1. Scope

1.1 This test method evaluates an engine oil's resistance to aeration in automotive diesel engine service. It is commonly referred to as the Caterpillar-C13 Engine-Oil Aeration Test (COAT). The test is conducted under high-engine-speed (1800 r/min), zero-load conditions using a specified Caterpillar 320 kW, direct-injection, turbocharged, after-cooled, six-cylinder diesel engine designed for heavy-duty, on-highway truck use. This test method was developed as a replacement for Test Method D6894.

NOTE 1 - Companion test methods used to evaluate engine oil performance for specification requirements are discussed in the latest revision of Specification D4485.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception - Where there is no direct SI equivalent, for example, screw threads, national pipe threads/diameters, and tubing size.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See Annex A2 for general safety precautions.

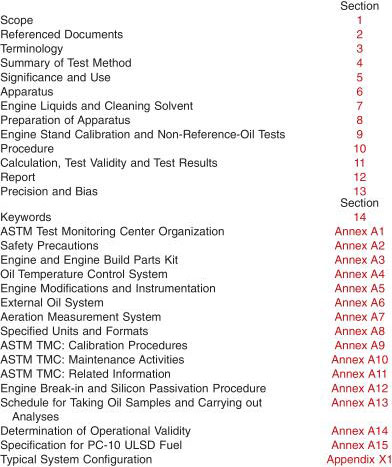

1.4 This test method is arranged as follows:

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products and Liquid Fuels at Atmospheric Pressure

D93 Test Methods for Flash Point by Pensky-Martens Closed Cup Tester

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Corrosiveness to Copper from Petroleum Products by Copper Strip Test

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D482 Test Method for Ash from Petroleum Products

D524 Test Method for Ramsbottom Carbon Residue of Petroleum Products

D613 Test Method for Cetane Number of Diesel Fuel Oil

D664 Test Method for Acid Number of Petroleum Products by Potentiometric Titration

D975 Specification for Diesel Fuel Oils

D976 Test Method for Calculated Cetane Index of Distillate Fuels

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D2274 Test Method for Oxidation Stability ofDistillate Fuel Oil (Accelerated Method)

D2709 Test Method for Water and Sediment in Middle Distillate Fuels by Centrifuge

D3524 Test Method for Diesel Fuel Diluent in Used Diesel Engine Oils by Gas Chromatography

D4052 Test Method for Density, Relative Density, and API Gravity of Liquids by Digital Density Meter

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4485 Specification for Performance ofActive API Service Category Engine Oils

D5185 Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

D5186 Test Method for Determination of the Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels By Supercritical Fluid Chromatography

D5453 Test Method for Determination of Total Sulfur in Light Hydrocarbons, Spark Ignition Engine Fuel, Diesel Engine Fuel, and Engine Oil by Ultraviolet Fluorescence D6078 Test Method for Evaluating Lubricity ofDiesel Fuels by the Scuffing Load Ball-on-Cylinder Lubricity Evaluator (SLBOCLE)

D6894 Test Method for Evaluation ofAeration Resistance of Engine Oils in Direct-Injected Turbocharged Automotive Diesel Engine

D7549 Test Method for Evaluation of Heavy-Duty Engine Oils under High Output Conditions - Caterpillar C13 Test Procedure

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

3. Terminology

3.1 Definitions:

3.1.1 automotive, adj - descriptive of equipment associated with self-propelled machinery, usually vehicles driven by internal combustion engines.

3.1.2 blowby, n - in internal combustion engines, that portion of the combustion products and unburned air/fuel mixture that leaks past piston rings into the engine crankcase during operation.

3.1.3 break-in, v - in internal combustion engines, the running of a new engine under prescribed conditions to help stabilize engine response and help remove initial friction characteristics associated with new engine parts.

3.1.4 calibrate, v - to determine the indication or output of a measuring device or a given engine with respect to a standard.

3.1.5 calibrated test stand, n - a test stand on which the testing of reference material(s), conducted as specified in the standard, provided acceptable test results.

3.1.5.1 Discussion - In several automotive lubricant standard test methods, the ASTM Test Monitoring Center provides testing guidance and determines acceptability.

3.1.6 calibration oil, n - an oil that is used to determine the indication or output of a measuring device or a given engine with respect to a standard.

3.1.7 calibration test, n - an engine test conducted on a reference oil under carefully prescribed conditions, the results of which are used to determine the suitability of the engine stand/laboratory for such tests on non-reference oils.

3.1.7.1 Discussion - A calibration test also includes tests conducted on parts to ensure their suitability for use in reference and non-reference tests.

3.1.8 candidate oil, n - an oil that is intended to have the performance characteristics necessary to satisfy a specification and is to be tested against that specification.

3.1.8.1 Discussion - These oils are mainly submitted for testing as candidates to satisfy a specified performance; hence the designation of the term.

3.1.9 engine oil, n - a liquid that reduces friction or wear, or both, between the moving parts within an engine; removes heat particularly from the underside of pistons; and serves as combustion gas sealant for the piston rings.

3.1.9.1 Discussion - It may contain additives to enhance certain properties. Inhibition of engine rusting, deposit formation, valve train wear, oil oxidation, and foaming are examples.

3.1.10 foam, n - in liquids, a collection of bubbles formed in the liquid or on (at) its surface in which the air (or gas) is the major component on a volumetric basis.

3.1.11 heavy-duty engine, n - in internal combustion engine types, one that is designed to allow operation continuous at or close to its peak output.

3.1.11.1 Discussion - This type of engine is typically installed in large trucks and buses as well as farm, industrial, and construction equipment.

3.1.12 lubricant, n - any material interposed between two surfaces that reduces the friction or wear, or both, between them.

3.1.13 lubricant test monitoring system (LTMS), n - an analytical system in which ASTM calibration test data are used to manage lubricant test precision and severity (bias).

3.1.14 mass fraction of B, wB , n - mass of a component B in a mixture divided by the total mass ofall the constituents ofthe mixture.

3.1.14.1 Discussion - Values are expressed as pure numbers or the ratio of two units of mass (for example, mass fraction of lead is wB = 1.3 x 10(-6) = 1.3 mg/kg).

3.1.15 non-reference oil, n - any oil other than a reference oil; such as a research formulation, commercial oil, or candidate oil.

3.1.16 quality index (QI), n - a mathematical formula that uses data from controlled properties to calculate a value indicative of control performance.

3.1.17 quantity, n - in the SI, a measurable property of a body or substance where the property has a magnitude expressed as the product of a number and a unit; there are seven, well-defined base quantities (length, time, mass, temperature, amount of substance, electric current, and luminous intensity) from which all other quantities are derived (for example, volume, whose SI unit is the cubic metre).

3.1.17.1 Discussion - Symbols for quantities must be carefully defined; are written in italic font, can be upper or lower case, and can be qualified by adding further information in subscripts, or superscripts, or in parentheses (for example, Tfuel = 40 °C, where T is used as the symbol for the quantity temperature and T fuel is the symbol for the specific quantity fuel temperature).

3.1.18 reference oil, n - an oil of known performance characteristics, used as a basis for comparison.

3.1.18.1 Discussion - Reference oils are used to calibrate testing facilities, to compare the performance of other oils, or to evaluate other materials (such as seals) that interact with oils.

3.1.19 test oil, n - any oil subjected to evaluation in an established procedure.

3.1.19.1 Discussion - It can be any oil selected by the laboratory conducting the test. It could be an experimental product or a commercially available oil. Often it is an oil that is a candidate for approval against engine oil specifications (such as manufacturers' or military specifications, and so forth).

3.1.20 volume fraction ofB, φB , n - volume of component B divided by the total volume of the all the constituents of the mixture prior to mixing.

3.1.20.1 Discussion - Values are expressed as pure numbers or the ratio of two units of volume (for example, φB = 0.012 = 1.2 % = 1.2 cL/L).

3.2 Definitions of Terms Specific to This Standard:

3.2.1 aeration, n - in lubricants, the action of impregnating with air that forms foam bubbles in or on the surface of a lubricant or is entrained as a dispersion in that lubricant.

3.2.2 flush, n - the action of cleaning out the engine oil system using new test oil to remove any residues as well as to minimize possible carryover effect from the previous test oil.

3.3 Abbreviations and Acronyms:

3.3.1 ACERT - Advanced Combustion Emission Reduction Technology

3.3.2 ACM - Alkyl Acrylate Copolymer

3.3.3 BL - Baseline (refers to density of fresh, un-aerated oil at 90 °C)

3.3.4 BOT - Beginning of Test

3.3.5 CARB - California Air Resources Board

3.3.6 Cat - abbreviation for Caterpillar

3.3.7 COAT - Caterpillar-C13 Oil-Aeration Test

3.3.8 ELC - Extended-Life Coolant

3.3.9 EOAT - Engine-Oil Aeration Test

3.3.10 ET - Engine Technician

3.3.11 EOT - End of Test

3.3.12 FDM - Flow and Density Meter

3.3.13 ICP-AES - Inductively Coupled Plasma Atomic Emission Spectrometry

3.3.14 ID - Internal Diameter

3.3.15 LTMS - Lubricant Test Monitoring System

3.3.16 NPT - National Pipe Thread

3.3.17 OA - Oil Aeration

3.3.18 P/N - Part Number (applies only to parts sourced from Caterpillar)

3.3.19 QI - Quality Index

3.3.20 SLBOCLE - Scuffing Load Ball-on-Cylinder Lubricity Evaluator

3.3.21 TMC - Test Monitoring Center of ASTM

3.3.22 ULSD fuel - Ultra-Low-Sulfur Diesel fuel

3.4 Quantity Symbols:

3.4.1 OA - Oil Aeration, %, (see 11.1.1.3)

3.4.2 PSAMPLE - Pressure of the aerated oil sampled during the 50 h test determined as the average of the FDM inlet- and outlet-pressures (see 10.5.6.3)

3.4.3 T - Temperature (see 10.4.2.3)

3.4.4 TSAMPLE - Temperature of the aerated oil sampled during the 50 h test determined as the average of the FDM inlet- and outlet-temperatures (see 10.5.6.4)

3.4.5 ρ - density (see 10.4.2.3)

3.4.6 ρAIR - air density calculated at the temperature and pressure of the aerated oil sample during the 50 h test (see 11.1.1.2)

3.4.7 ρBL, 90 - baseline density of the unaerated fresh oil at 90 °C determined as the intercept of the D4052 density versus temperature regression (see 10.4.2.3)

3.4.8 ρSAMPLE - the measured FDM density of the aerated oil sampled during the 50 h test at the temperature TSAMPLE (see 10.5.6.4)

3.4.9 ρSAMPLE, 90 - the calculated FDM density of the aerated oil sampled during the 50 h test at 90 °C (see 11.1.1.1)

3.4.10

- temperature dependence of the baseline density of fresh, un-aerated oil determined as the slope of the density vs. temperature regression of fresh, un-aerated oil (see 10.4.2.3)

- temperature dependence of the baseline density of fresh, un-aerated oil determined as the slope of the density vs. temperature regression of fresh, un-aerated oil (see 10.4.2.3)