1. Scope

1.1 This test method covers the determination of several elements (including iron, nickel, sulfur, and vanadium) occurring in crude oils.

1.2 For analysis of any element using wavelengths below 190 nm, a vacuum or inert gas optical path is required.

1.3 Analysis for elements such as arsenic, selenium, or sulfur in whole crude oil may be difficult by this test method due to the presence of their volatile compounds of these elements in crude oil; but this test method should work for resid samples.

1.4 Because of the particulates present in crude oil samples, if they do not dissolve in the organic solvents used or if they do not get aspirated in the nebulizer, low elemental values may result, particularly for iron and sodium. This can also occur if the elements are associated with water which can drop out of the solution when diluted with solvent.

1.4.1 An alternative in such cases is using Test Method D5708, Procedure B, which involves wet decomposition of the oil sample and measurement by ICP-AES for nickel, vanadium, and iron, or Test Method D5863, Procedure A, which also uses wet acid decomposition and determines vanadium, nickel, iron, and sodium using atomic absorption spectrometry.

1.4.2 From ASTM Interlaboratory Crosscheck Programs (ILCP) on crude oils data available so far, it is not clear that organic solvent dilution techniques would necessarily give lower results than those obtained using acid decomposition techniques.

1.4.3 It is also possible that, particularly in the case of silicon, low results may be obtained irrespective of whether organic dilution or acid decomposition is utilized. Silicones are present as oil field additives and can be lost in ashing. Silicates should be retained but unless hydrofluoric acid or alkali fusion is used for sample dissolution, they may not be accounted for.

1.5 This test method uses oil-soluble metals for calibration and does not purport to quantitatively determine insoluble particulates. Analytical results are particle size dependent and low results may be obtained for particles larger than a few micrometers.

1.6 The precision in Section 18 defines the concentration ranges covered in the interlaboratory study. However, lower and particularly higher concentrations can be determined by this test method. The low concentration limits are dependent on the sensitivity of the ICP instrument and the dilution factor used. The high concentration limits are determined by the product of the maximum concentration defined by the calibration curve and the sample dilution factor.

1.7 Elements present at concentrations above the upper limit of the calibration curves can be determined with additional appropriate dilutions and with no degradation of precision.

1.8 As a generality based on this interlaboratory study (see 18.1), the trace elements identifiable in crude oils can be divided into three categories:

1.8.1 Element levels that are too low for valid detection by ICP-AES and hence, cannot be determined: aluminum, barium, lead, magnesium, manganese, and silicon.

1.8.2 Elements that are just at the detection levels of the ICP-AES method and hence, cannot be determined with a great deal of confidence: boron, calcium, chromium, copper, molybdenum, phosphorus, potassium, sodium, and zinc. Perhaps the determination of these elements can be considered as semi-quantitative.

1.8.3 Elements that are at higher levels of concentration and can be determined with good precision: iron, nickel, sulfur, and vanadium.

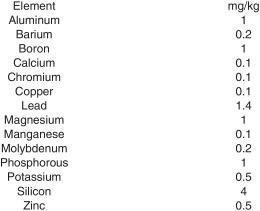

1.9 The detection limits for elements not determined by this test method follow. This information should serve as an indication as to what elements are not present above the detection limits typically obtainable by ICP-AES instruments.

1.10 This test method determines all possible elements simultaneously and is a simpler alternative to Test Methods D5184, D5708, or D5863.

1.11 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.12 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C1109 Practice for Analysis of Aqueous Leachates from Nuclear Waste Materials Using Inductively Coupled Plasma-Atomic Emission Spectroscopy

D1552 Test Method for Sulfur in Petroleum Products by High Temperature Combustion and IR Detection

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D4307 Practice for Preparation of Liquid Blends for Use as Analytical Standards

D5184 Test Methods for Determination of Aluminum and Silicon in Fuel Oils by Ashing, Fusion, Inductively Coupled Plasma Atomic Emission Spectrometry, and Atomic Absorption Spectrometry

D5185 Test Method for Multielement Determination of Used and Unused Lubricating Oils and Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

D5708 Test Methods for Determination of Nickel, Vanadium, and Iron in Crude Oils and Residual Fuels by Inductively Coupled Plasma (ICP) Atomic Emission Spectrometry

D5854 Practice for Mixing and Handling of Liquid Samples of Petroleum and Petroleum Products

D5863 Test Methods for Determination of Nickel, Vanadium, Iron, and Sodium in Crude Oils and Residual Fuels by Flame Atomic Absorption Spectrometry

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measurement System Performance

D6792 Practice for Quality System in Petroleum Products and Lubricants Testing Laboratories

D7260 Practice for Optimization, Calibration, and Validation of Inductively Coupled Plasma-Atomic Emission Spectrometry (ICP-AES) for Elemental Analysis of Petroleum Products and Lubricants

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

3. Terminology

3.1 For the definition of emission spectroscopy, refer to Terminology E135.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 analyte, n - element whose concentration is being determined.

3.2.2 Babington-type nebulizer, n - device that generates an aerosol by flowing a liquid over a surface that contains an orifice from which gas flows at a high velocity.

3.2.3 calibration, n - process by which the relationship between signal intensity and elemental concentration is determined for a specific element analysis.

3.2.4 calibration curve, n - plot of signal intensity versus elemental concentration using data obtained by making measurements with standards.

3.2.5 detection limit, n - concentration of an analyte that results in a signal intensity that is some multiple (typically two) times the standard deviation of the background intensity at the measurement wavelength.

3.2.6 inductively-coupled plasma (ICP), n - high-temperature discharge generated by flowing an ionizable gas through a magnetic field induced by a load coil that surrounds the tubes carrying the gas.

3.2.7 linear response range, n - elemental concentration range over which the calibration curve is a straight line, within the precision of the test method.

3.2.8 profiling, n - technique that determines the wavelength for which the signal intensity measured for a particular analyte is a maximum.

3.2.9 radio frequency (RF), n - range of frequencies between the audio and infrared ranges (3 GHz to 300 GHz).