5. Materials and Manufacture

5.1 Unleaded aviation gasoline, except as otherwise specified in this specification, shall consist of blends of refined hydrocarbons derived from crude petroleum, natural gasoline, or blends, thereof, with synthetic hydrocarbons or aromatic hydrocarbons, or both.

5.2 Additives - These may be added to each grade of unleaded aviation gasoline in the amount and of the composition specified in the following list of approved materials. The quantities and types shall be declared by the manufacturer. Additives added after the point of manufacture shall also be declared.

5.2.1 Antioxidants - The following oxidation inhibitors may be added to the gasoline separately, or in combination, in total concentration not to exceed 12 mg of inhibitor (not including weight of solvent) per litre of fuel.

5.2.1.1 2,6-ditertiary butyl-4-methylphenol.

5.2.1.2 2,4-dimethyl-6-tertiary butylphenol.

5.2.1.3 2,6-ditertiary butylphenol.

5.2.1.4 75 % minimum 2,6-ditertiary butylphenol plus 25 % maximum mixed tertiary and tritertiary butylphenols.

5.2.1.5 75 % minimum di- and tri-isopropyl phenols plus 25 % maximum di- and tri-tertiary butylphenols.

5.2.1.6 72 % minimum 2,4-dimethyl-6-tertiary butylphenol plus 28 % maximum monomethyl and dimethyl tertiary butylphenols.

5.2.1.7 N,N’-di-isopropyl-para-phenylenediamine.

5.2.1.8 N,N’-di-secondary-butyl-para-phenylenediamine.

5.2.2 Fuel System Icing Inhibitor (FSII) - One of the following may be used:

5.2.2.1 Isopropyl Alcohol (IPA, propan-2-ol), in accordance with the requirements of Specification D4171 (Type II). May be used in concentrations recommended by the aircraft manufacturer when required by the aircraft owner/operator.

NOTE 2 - Addition of isopropyl alcohol (IPA) can reduce knock ratings below minimum specification values (see X1.2.3).

5.2.2.2 Di-Ethylene Glycol Monomethyl Ether (Di-EGME), conforming to the requirements of Specification D4171 (Type III) may be used in concentrations of 0.10 to 0.15 volume % when required by the aircraft owner/operator.

5.2.2.3 Test Method D5006 may be used to determine the concentration of Di-EGME in aviation fuels.

5.2.3 Electrical Conductivity Additive - Stadis 450 in concentrations up to 3 mg/L is permitted. When loss of fuel conductivity necessitates retreatment with electrical conductivity additive, further addition is permissible up to a maximum cumulative level of 5 mg/L of Stadis 450.

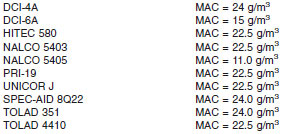

5.2.4 Corrosion Inhibitor Additive - The following corrosion inhibitors may be added to the gasoline in concentrations not to exceed the maximum allowable concentration (MAC) listed for each additive.

6. Detailed Requirements

6.1 The unleaded aviation gasoline shall conform to the requirements prescribed in Table 1.

6.2 Test results shall not exceed the maximum or be less than the minimum values specified in Table 1. No allowance shall be made for the precision of the test methods. To determine the conformance to the specification requirement, a test result may be rounded to the same number of significant figures as in Table 1 using Practice E29. Where multiple determinations are made, the average result, rounded according to Practice E29, shall be used.

7. Workmanship, Finish, and Appearance

7.1 The unleaded aviation gasoline specified in this specification shall be free from undissolved water, sediment, and suspended matter. The odor of the fuel shall not be nauseating or irritating. No substances of known dangerous toxicity under usual conditions of handling and use shall be present.

8. Sampling

8.1 Because of the importance of proper sampling procedures in establishing fuel quality, use the appropriate procedures in Practice D4057 or Practice D4177.

8.1.1 Although automatic sampling following Practice D4177 may be useful in certain situations, initial refinery specification compliance testing shall be performed on a sample taken following procedures in Practice D4057.

8.2 A number of unleaded aviation gasoline properties, including copper corrosion, electrical conductivity, and others are very sensitive to trace contamination which can originate from sample containers. For recommended sample containers, refer to Practice D4306.