13. Report

13.1 In cases in which no specific data requirements have been set by the operator, corrected temperatures readings versus corresponding percent recovered or evaporated are typically reported by the apparatus. Report typically contains the IBP, FBP, 5 %, 95 % and each 10 % increment from 10 % to 90 %, as well as percent recovery and percent residue.

13.1.1 If required, the percent loss is calculated by the following equation:

loss % = 100 - (percent recovery + percent residue)

13.2 Report all volumetric percentages to the nearest 0.1 % (V/V).

13.3 Report all temperature readings to the nearest 0.1 °C (see Note 3).

13.4 Report if a drying agent, as described in 8.3.2, was used.

13.5 The test report shall contain at least the following information:

13.5.1 Sufficient details for complete identification of the product tested;

13.5.2 A reference to this standard;

13.5.3 The result of the test;

13.5.4 Any deviation, by agreement or otherwise, from the procedure specified; and

13.5.5 The date of the test.

14. Precision and Bias

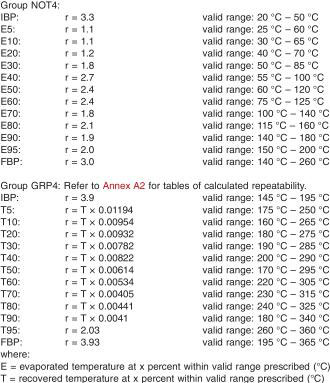

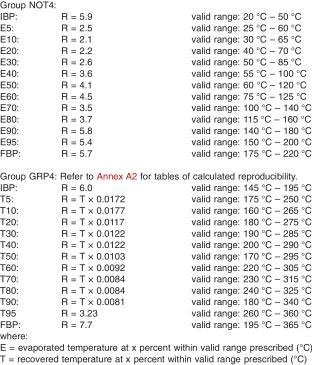

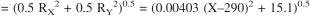

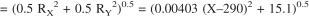

14.1 Precision - The precision of this test method as determined by the statistical examination of the interlaboratory test results is as follows:

NOTE 6 - Typically samples for distillation are classified according to a Group number (see Test Method D86). However, this test method does not require this classification, but for the purposes of precision and cross method reproducibility comparisons, the precisions and bias have been derived according to the group number in the following fashion. Group 1, 2, and 3 samples are labeled as NOT4, and Group 4 samples are labeled GRP4. See Appendix X1 for further information on typical samples and group classification.

NOTE 7 - Information on the precision of % evaporated or % recovered at a prescribed temperature can be found in Annex A4.

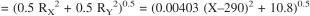

14.1.1 Repeatability - The difference between successive test results, obtained by the same operator using the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of this test method, exceed the following only in one case in twenty.

NOTE 8 - For naphthas, solvents, and other similar materials where percent recovered is reported and the percent loss is typically less than one percent, the percent recovered temperatures can be considered identical to the percent evaporated temperatures, and precision can be calculated as shown for Group NOT4.

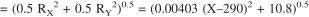

14.1.2 Reproducibility - The difference between two single and independent test results, obtained by different operators working in different laboratories on identical test material, would in the long run, in normal and correct operation of this test method, exceed the following only in one case in twenty.

NOTE 9 - See Note 8.

NOTE 10 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 Group NOT4 precision for E5 are 25. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

NOTE 11 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 Group NOT4 precision for E10 are 27. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

NOTE 12 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 Group NOT4 precision for E95 are 25. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

14.2 Bias - Since there is no accepted reference material suitable for determining the bias for the procedure in this Test Method, bias has not been determined.

14.3 Between-Method Bias - The Degree of Agreement between results by Test Method D7345 and Test Method D86 (automated) - Results on the same materials produced by Test Method D7345 and Test Method D86 have been assessed in accordance with procedures outlined in Practice D6708. The findings are:

IBP:

NOT4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 2. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X + 1.42 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 2 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (R xy ), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

No bias-correction considered in Practice D6708 can further improve agreement between results from Test Method D7345 and Test Method D86 (automated), for sample types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T5:

NOT4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 3. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 0.82 X + 11.25 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 4. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 1.1 X - 18.43 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 4 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (R xy ), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T10:

NOT4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 5. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 0.82 X + 11.1 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 6. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 1.09 X - 16.4 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 6 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T20:

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 7. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X + 0.96 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 8. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 1.09 X - 18.88 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 8 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T30:

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated) for the material types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 9. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 1.08X - 18.5 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 9 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T40:

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated) for the material types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 10. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 1.06 X - 15.71 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 10 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T50:

NOT4

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated) for the material types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 11. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X - 2.015 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T60:

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 12. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X =predicted Y = 0.68X + 35.86 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 13. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X - 1.84 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 13 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T70:

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 14. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 0.8X + 24.27 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 15. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X - 1.79 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 15 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T80:

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 16. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = 0.83X + 22.87 °C

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 17. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X - 1.46 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 17 and Test Method D86, for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T90:

NOT4

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated), for sample types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 18. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X - 0.67 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

T95:

NOT4

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated) for the material types and property ranges studied.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

No bias-correction considered in Practice D6708 can further improve the agreement between results from Test Method D7345 and Test Method D86 (automated) for the material types and property ranges studied. Sample-specific bias, as defined in Practice D6708, was observed for some samples.

Differences between results from Test Method D7345 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

FBP:

NOT4

The degree of agreement between results from Test Method D7345 and Test Method D86 (automated) can be further improved by applying the bias-correction outlined in Eq 19. Sample-specific bias, as defined in Practice D6708, was observed for some samples after applying the bias-correction.

Bias-corrected X = predicted Y = X + 1.09 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 19 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group NOT4: Refer to Annex A3.

GRP4

Bias-corrected results from Test Method D7345, as per the bias correction equation (Eq 20), may be considered as practically equivalent to results from Test Method D86 (automated), for sample types and property ranges studied. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction, for the materials studied.

Bias-corrected X = predicted Y = 1.02 X - 5.90 °C

where:

X = result obtained by Test Method D7345 (this test method), and bias-corrected X = predicted Y = result that would have been obtained by Test Method D86 (automated) on the same sample.

Differences between bias-corrected results from Eq 20 and Test Method D86 (automated), for the sample types and property ranges studied, are expected to exceed the following cross method reproducibility (Rxy), as defined in Practice D6708, about 5 % of the time.

Group GRP4: Refer to Annex A3.

14.4 The precision statements for Group GRP4 were derived according to Practice D6300 from a 2005 interlaboratory cooperative test program. Sixteen laboratories have participated and analyzed 18 sample sets comprising specification grade diesel (with a B5 and B20 biodiesel), specification grade heating oil, aviation turbine fuels, marine fuels, mineral spirits, and toluene. The temperature range covered was 145 °C to 365 °C. Information on the type of samples and their average boiling points are in the research report.

14.5 The precision statements for Group NOT4 were derived from a 2010 interlaboratory cooperative test program. Twenty-six laboratories participated and analyzed twenty-one sample sets comprised of specification grade gasoline, both conventional and oxygenated, some containing up to 20 % ethanol. The temperature range covered was 20 °C to 220 °C. Information on the type of samples and their average boiling points are in the research report.

14.6 Precision (Biodiesel B100) - The precision of this test method when applied to biodiesel (FAME) as determined by the statistical examination of the interlaboratory test results is as follows:

14.6.1 Repeatability - The difference between successive test results, obtained by the same operator using the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of this test method, exceed the values in Table 1 only in one case in twenty.

14.6.2 Reproducibility - The difference between two single and independent test results, obtained by different operators working in different laboratories on identical test material, would in the long run, in normal and correct operation of this test method, exceed the values in Table 1 only in one case in twenty.

NOTE 13 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 biodiesel (B100) precision for IBP are 20. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

NOTE 14 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 biodiesel (B100) precision for 5 % to 95 % are 15. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

NOTE 15 - The degrees of freedom associated with the reproducibility estimate from this interlaboratory study for D7345 biodiesel (B100) precision for FBP are 21. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

14.6.3 The precision statements for biodiesel (B100) were derived from a 2012 interlaboratory cooperative test program. The precision and relative bias are applicable only to the biodiesel sample types listed in the research report. A total of nine participating laboratories using various Test Method D1160 automated, automatic, or manual apparatus; and twelve participating laboratories using D7345 apparatus; analyzed blind replicates of eleven sample sets comprised of eight specification grade biodiesel (B100) (derived from soy, canola, tallow and yellow grease), two mixed blends of biodiesel (B100) (soy and tallow), and a mustard oil. The distillation range was from 274 °C to 400 °C. Information on the type of samples and their average boiling points are in the research report.

14.7 Bias (Biodiesel B100) - Since there is no accepted reference material suitable for determining the bias for the procedure in this test method, bias has not been determined.

14.8 Relative Bias (Biodiesel B100) - The degree of agreement between results by Test Method D7345 and Test Method D1160; results on the same materials produced by Test Method D7345 and Test Method D1160 have been assessed in accordance with procedures outlined in Practice D6708. The findings are:

14.8.1 For IBP - Test material property differences cannot be reliably distinguished by either Test Method D7345, or Test Method D1160, or both.

14.8.2 For T5 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 21) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = 1.164 (X - 343.2) + 343.8

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.2.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.3 For T10 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 22) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = X + 0.66

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.3.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.4 For T20 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 23) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = X + 0.79

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.4.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.5 For T30 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 24) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = X + 1.07

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.5.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.6 For T40 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 25) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = 0.781 (X - 346.7) + 347.9

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.6.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.7 For T50 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 26) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = 0.742 (X - 347.3) + 348.8

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.7.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.8 For T60 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 27) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = 0.681 (X - 348) + 349.8

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.8.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.9 For T70 - The degree of agreement between results from Test Method D7345 and Test Method D1160, can be further improved by applying correction equation (Eq 28) as listed below. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials and property range studied.

Bias-corrected X = predicted Y = 0.522 (X - 348.8) + 350.6

where:

X = result in °C obtained by Test Method D7345 (this test method), and

bias-corrected X = predicted Y = result that would have been obtained by Test Method D1160 on the same sample.

14.8.9.1 Differences between bias-corrected results from Test Method D7345 and Test Method D1160, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. Between Methods R

14.8.10 For T80 - Test material property differences cannot be reliably distinguished by either Test Method D7345, or Test Method D1160, or both.

14.8.11 For T90 - Test material property differences cannot be reliably distinguished by either Test Method D7345, or Test Method D1160, or both.

14.8.12 For T95 - There is an insufficient degree of agreement (correlation) between Test Method D7345 and Test Method D1160.

14.8.13 For FBP - Test material property differences cannot be reliably distinguished by either Test Method D7345, or Test Method D1160, or both.

15. Keywords

15.1 batch distillation; boiling range distribution; distillates; distillation; laboratory distillation; micro distillation; petroleum products