ASTM D7169 Standard Test Method for Boiling Point Distribution of Samples with Residues Such as Crude Oils and Atmospheric and Vacuum Residues by High Temperature Gas Chromatography

16. Calculations

NOTE 2 - The calculations are listed in this section. The chromatogram for the reference oil, the sample, and the baseline shall be zeroed as given in 16.1.2.

NOTE 3 - The baseline chromatogram is subtracted from the Reference Oil 5010 and from the sample chromatogram in order to obtain the net area as shown in 16.1.4.

16.1 Zeroing of the Reference Oil Chromatogram:

16.1.1 Examine the chromatogram obtained for Reference Oil 5010 (external standard), and ensure, by visual inspection of the chromatogram in the data system, that the first 5 slices contain neither sample nor solvent elution.

16.1.2 Set up an array that contains slices obtained from the Reference Oil 5010 chromatogram. Calculate the average of the first five area slices. Subtract the average slice area from each slice in the Reference Oil 5010 chromatogram. Set negative numbers to zero.

16.1.3 Zero the blank baseline chromatogram by carrying out an analogous calculation as in 16.1.2.

16.1.4 Blank Baseline Subtraction from the Reference Oil 5010 Chromatogram - Subtract each zeroed blank baseline slice from the corresponding zeroed Reference Oil 5010 slice. If there are negative slices, set the slice values to zero.

16.1.5 Determination of the End of Elution Time of Reference Oil 5010 - Since it is a requirement that the sample chosen to obtain a response factor shall fully elute prior to the FEt time, the end of sample elution for this chromatogram is to be determined as described in Test Method D6352, using the algorithm to determine the time the signal of the completely eluted sample returns to baseline.

16.1.6 Determination of the Area of the Chromatogram for Reference Oil 5010 - Determine the end time of solvent elution. Sum all of the slices from the end of solvent elution to the end of sample elution. This is the area of the standard, ASTD.

16.1.7 Calculation of the Boiling Point Distribution of Reference Oil 5010 - The resulting corrected slices obtained for Reference Oil 5010 are submitted to a Test Method D6352 calculation for boiling point distribution. A comparison of the values obtained with the consensus values listed in Table 2 shall be made and all the boiling point values shall fall within the specified windows. If this requirement is not met, correct any chromatographic problems prior to proceeding with sample analysis. Typical problems found in this step are: contaminated solvent; problems in sample preparation; sample residue in the inlet or column, or both; quality of the baseline used, a partially blocked detector jet, or a combination thereof.

16.2 Zeroing of Sample Chromatograms:

16.2.1 In the case of crude oil analysis or samples in which the solvent peak is not resolved from the sample components, ensure, by visual inspection of the chromatogram in the data system, that the first 5 slices contain neither sample nor solvent elution. If there is sample elution, decrease the number of slices for the averaging to 3 or increase the digitization rate given in 12.2.

16.2.2 Zeroing the Sample Chromatogram - Proceed in a manner analogous to that described in 16.1.2.

16.2.3 Zeroing the Blank Baseline Chromatogram - Carry out an analogous calculation as in 16.1.3.

16.3 Blank Baseline Subtraction from the Sample Chromatogram - Carry out an analogous calculation as in 16.1.4.

16.4 Quenching Correction - For crude oil samples, a quenching factor is used to correct for the diminished FID response when the CS2 co-elutes with sample components. This factor is applied to the time segment corresponding to the elution of CS2. In the interlaboratory study, the factor of 1.930 was applied. This value is determined from experiments made by dissolving butane, pentane, and hexane in toluene. The solution is analyzed by injecting it under conditions identical to sample analysis. The areas for the components are compared to the areas obtained by gradually adding weighed aliquots of CS2 to the original solution. Alternatively the quenching value can be checked by performing a glass distillation by Test Method D2892. Samples that do not have components that co-elute with solvent, for example, residues or the Reference Oil 5010, do not require the quenching correction.

16.4.1 Determine the Quenching Interval - Select the time that the solvent peak starts to elute. Determine when the solvent peak has eluted. Note the times of this interval in minutes. An expanded time scale chromatogram of the solvent peak is shown in Fig. A1.7.

16.4.2 Locate the slices of the quenching interval. For samples in which the solvent component co-elutes with the sample chromatogram (that is, crude oils), determine the quenching interval, Q.I., as described in 16.4.1. Find the closest slice corresponding to the beginning of elution of the solvent peak as well as the final slice corresponding to the end of elution of the solvent peak.

16.4.3 Correct the diminished response of the interval by multiplying each slice of this interval by the quenching factor, Q.F. Use the value as discussed in 16.4.

16.5 Determination of the Sample Final Elution Time - Determine the time at which the oven reaches the isothermal portion of the temperature program. This is usually recognized as an inflection point in the baseline. This point is called the final elution time (FEt). The conversion of this slice to temperature will yield the final elution temperature, FET. This conversion is carried out in 16.9.4.

16.6 Determination of the Sample Area - The net sample area is obtained by adding all slices from time t = 0 to the final elution time, FEt. This net area is the ASMP.

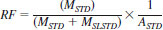

16.7 Calculate the Response Factor, RF, as follows:

where:

RF = response factor,

ASTD = net area obtained for the Reference Oil 5010 chromatogram after baseline subtraction and after excluding the solvent peak (this area was determined in 16.1.6),

MSLSTD = solvent mass, in grams, used for Reference Oil dissolution, and

MSTD = mass, in grams, of Reference Oil 5010 used in preparing the response factor solution.

16.7.1 The mass term in Eq 4 has been expressed as a fraction of the mass of solute and solvent.

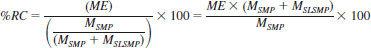

16.8 Calculation of the %Recovery - The %recovery is defined as:

where:

ME = mass, in grams, of the sample eluted,

MSMP = sample mass, in grams, and

MSLSMP = mass of solvent, in grams, used in the sample solution.

Since:

ME = (ASMP) x (RF)

where:

ASMP = net sample area, and

RF = response factor of the Reference Oil 5010.

Substituting Eq 6 for the value of ME in Eq 5 yields:

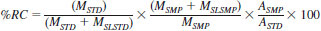

Substituting Eq 4 in Eq 7 for the value of RF yields:

16.8.1 Determine whether the %recovery, (%RC) falls below the recovery threshold (Rt) limits set. If it is less than or equal to the recovery threshold (Rt), use the %recovery (%RC) determined in 16.8. If the %recovery is greater than the recovery threshold (Rt), then the recovery is set to 100 %. If the %recovery is larger than 102 % (1 standard deviation of the residue), repeat the analysis or determine the chromatographic problem.

16.9 Determination of the Boiling Point Distribution:

16.9.1 Multiply each slice of the sample chromatogram by the %recovery as established in 16.8.1. Divide each slice by the total area of the sample obtained in 16.6. This will express the slices in a percent scale.

16.9.2 Add the slices that will yield 0.5 %, 1 %, 2 %, . . . %recovery. Determine, at 1 % intervals, the time of the slice yielding exactly 0.5, 1 %, 2 %, ...%recovery. Use an interpolation procedure to find the fractional slices required to yield exactly 0.5, 1 %, ...2 %, ...%recovery.

16.9.3 Stop the calculation carried out in 16.9.2 when obtaining a slice summation equal to the nearest whole integer of the %recovery.

16.9.4 Convert the retention times to boiling points as outlined in the Test Method D6352 algorithm. Use the boiling point temperatures listed in Table 3. For each retention time obtained in 16.9.2, find the corresponding temperature from the Boiling Point vs. Retention Time function as shown in Fig. A1.8. Calculate the corresponding boiling points as determined in the Test Method D2887 algorithm.

16.10 Calculation of Cut Point Intervals:

16.10.1 For the two temperatures that define the cut point interval, find the two corresponding slices.

16.10.2 Using the calibration curve, convert this temperature range to a time range.

16.10.3 Convert the time range to a slice number range by multiplying by 60 and dividing by the slice width in seconds.

16.10.4 Sum the normalized slices, starting with the initial slice of the cut and terminating with the last slice after the cut. This sum will be equal to the %mass of the cut.

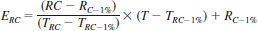

16.10.5 The %recovery, RC, determined at a temperature TRC that is equal to or less than FET, can be determined at a new temperature TN by using the following equation:

where:

ERC = estimated recovery at temperature T,

%RC = %recovery determined at temperature TRC in 16.8.1,

%RC-1% = %recovery determined at 1 % below the %RC, and

TRC-1% = temperature corresponding to RC-1%.

16.10.5.1 The use of this equation for values TN > FET is not recommended.