ASTM D7169 Standard Test Method for Boiling Point Distribution of Samples with Residues Such as Crude Oils and Atmospheric and Vacuum Residues by High Temperature Gas Chromatography

1. Scope

1.1 This test method covers the determination of the boiling point distribution and cut point intervals of crude oils and residues by using high temperature gas chromatography. The amount of residue (or sample recovery) is determined using an external standard.

1.2 This test method extends the applicability of simulated distillation to samples that do not elute completely from the chromatographic system. This test method is used to determine the boiling point distribution through a temperature of 720°C. This temperature corresponds to the elution of n-C100.

1.3 This test method is used for the determination of boiling point distribution of crude oils. This test method uses capillary columns with thin films, which results in the incomplete separation of C4-C8 in the presence of large amounts of carbon disulfide, and thus yields an unreliable boiling point distribution corresponding to this elution interval. In addition, quenching of the response of the detector employed to hydrocarbons eluting during carbon disulfide elution, results in unreliable quantitative analysis of the boiling distribution in the C4-C8 region. Since the detector does not quantitatively measure the carbon disulfide, its subtraction from the sample using a solvent-only injection and corrections to this region via quenching factors, results in an approximate determination of the net chromatographic area. A separate, higher resolution gas chromatograph (GC) analysis of the light end portion of the sample may be necessary in order to obtain a more accurate description of the boiling point curve in the interval in question (see Appendix X1).

1.4 This test method is also designed to obtain the boiling point distribution of other incompletely eluting samples such as atmospheric residues, vacuum residues, etc., that are characterized by the fact that the sample components are resolved from the solvent.

1.5 This test method is not applicable for the analysis of materials containing a heterogeneous component such as polyesters and polyolefins.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in Section 8.

2. Referenced Documents

2.1 ASTM Standards:

D2887 Test Method for Boiling Range Distribution of Petroleum Fractions by Gas Chromatography

D2892 Test Method for Distillation of Crude Petroleum (15-Theoretical Plate Column)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D6352 Test Method for Boiling Range Distribution of Petroleum Distillates in Boiling Range from 174 to 700°C by Gas Chromatography

D6729 Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 100 Metre Capillary High Resolution Gas Chromatography

D6730 Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 100-Metre Capillary (with Precolumn) High-Resolution Gas Chromatography

E594 Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

E1510 Practice for Installing Fused Silica Open Tubular Capillary Columns in Gas Chromatographs

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 cut point interval, n - the mass % obtained between two selected temperatures of the interval.

3.1.2 data acquisition rate, n - the speed of conversion of the analog signal to a digital signal, expressed in Hz (cycles/second).

3.1.3 final boiling point (FBP), n - the temperature, for fully eluting samples (recovery = 100 %), at which 99.5 % of the sample is eluted.

3.1.4 final elution time (FEt), n - the retention time of the component of the reference time standard sample that elutes at the end of the temperature ramp of the oven.

3.1.5 final elution temperature (FET), n - the boiling point of the normal paraffin that elutes at the time when the oven reaches its final temperature.

3.1.6 initial boiling point (IBP), n - the temperature corresponding to an accumulated 0.5 % of the total area of the eluted sample after correcting for the percent of sample recovery.

3.1.7 quenching factor (QF), n - a number that corrects for the diminished response due to the solvent profile co-eluting with sample components.

3.1.7.1 Discussion - Data acquired during the quenching interval (QI) shall be corrected by applying the quenching factor.

3.1.8 quenching interval (QI), n - the time interval of the start and end of elution of the CS2 used as a solvent.

3.1.8.1 Discussion - Sample components that elute during this time interval shall be corrected by a factor due to their diminished response resulting from the co-elution of the relatively large amount of solvent present in the sample with the light sample components.

3.1.9 residue (R), n - the mass % of the sample that has not eluted at the temperature of calculation.

3.1.9.1 Discussion - Residue is calculated from the % recovery.

3.1.10 response factor (RF), n - the factor used in order to calculate the % recovery of the sample.

3.1.10.1 Discussion - The response factor is determined from the net area of the standard (ASTD), mass of standard (MSTD), and mass of solvent (MSLSTD) used in the solution of the standard. A fully eluting sample, such as Reference Oil 5010, is used in obtaining the response factor.

3.1.11 sample area obtained (ASMP), n - the net chromatographic area (after baseline subtraction) obtained for the sample at the final elution time or temperature.

3.1.12 slice, n - the reciprocal of the data acquisition rate; the time interval used to accumulate data, expressed in seconds.

3.1.12.1 Discussion - Normally 0.1 s is used. In cases where sample elutes immediately after injection, 0.05 s is used.

3.1.13 start elution temperature (SET), n - the temperature at which the first amount of hydrocarbon is detected by the flame ionization detector above a predetermined threshold.

3.1.14 %recovery (RC), n - percentage of the sample eluted.

3.1.14.1 Discussion - % Recovery is calculated from the sample area (ASMP), the response factor (RF), the sample mass, (MSMP), and the solvent mass (MSLSMP) used in sample dissolution.

3.1.15 %recovery threshold (Rt), n - if the %recovery falls above a preset limit, the sample is considered fully eluted and its recovery is assumed to be 100 %.

3.1.15.1 Discussion - If the %recovery values found for duplicate analyses of a nearly completely eluting sample are 99.6 and 101.2 %, the %recovery threshold (Rt) may be set to 99.6 % and thus either of these results may be considered as fully eluted and set to 100 %.

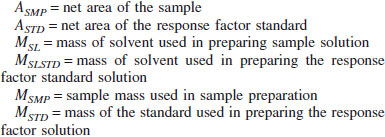

3.2 Symbols: