ASTM D7112 Standard Test Method for Determining Stability and Compatibility of Heavy Fuel Oils and Crude Oils by Heavy Fuel Oil Stability Analyzer (Optical Detection)

15. Calculation of Results

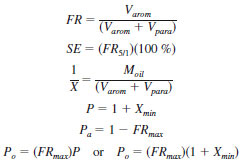

15.1 The instrument automatically calculates the stability parameters by linear regression and by extrapolation (see Fig. 4), using the following equations:

where:

FR = flocculation ratio,

FR5/1 = flocculation ratio at a dilution of 5 mL solution to 1 g of oil,

FRmax = maximum flocculation ratio (at 1/X = 0),

SE = aromatic solvent equivalent, expressed as a percent value,

1/X = oil to solution ratio, g/mL,

Xmin = paraffinic solvent consumption of undiluted oil, mL/g of oil (at FR = 0),

Moil = mass of oil, g,

Varom = volume of aromatic solvent in the mixture, mL,

Vpara = volume of paraffinic solvent in the mixture, mL,

P = P-value of an oil,

Pa = peptizability of an asphaltene, and

Po = peptizing power of the oil matrix.

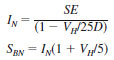

15.2 The instrument uses the following equations to determine compatibility parameters of crude oil samples, if required:

where:

IN = insolubility number,

SBN = solubility blending number,

D = density of oil, g/mL,

SE = aromatic solvent equivalent, volume %, and

VH = volume of paraffinic solvent that can be added to 5

mL of oil without asphaltene precipitation.

16. Report

16.1 Report the following information:

16.1.1 The identity of the sample,

16.1.2 The stability parameters: SE, P-value, and FR5/1,

16.1.3 The compatibility parameters: IN and SBN, if determined,

16.1.4 Reference to this test method, and

16.1.5 If an elevated temperature above ambient room temperature was used, report the temperature of the test.

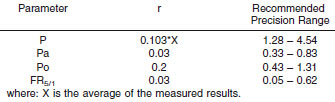

17. Precision and Bias

17.1 Precision - The precision statements for P, Pa, Po, and FR5/1 are based on results from an interlaboratory study that involved 11 samples (heavy fuel oils, atmospheric and visbroken residues and crude oils) that contained from 0.7 to 22.5 % by mass asphaltenes as measured using Test Method D6560. Five operators used three instruments at one location to develop the repeatability precision. The recommended ranges for applicability of the precision follow. The recommended precision range is determined by:

NOTE 9 - The precision of this test method may not apply to samples outside the range of materials examined in the research report.

17.1.1 Repeatability - The difference between successive results obtained by the same operator with the same apparatus, under constant operating conditions, on identical test materials would, in the long run, in the normal and correct operation of this test method, exceed the values in 17.1 only in one case in twenty.

The recommended precision range is determined by: (min. sample mean - repeatability) to (max. sample mean + repeatability).

17.1.2 Reproducibility - Reproducibility has not been evaluated because it is not relevant to the intended application of this test method, and typical samples are sufficiently unstable that results from different laboratories, performed at different times on samples that have been exposed to varying storage conditions, will be suspect.

17.2 This test method has no bias because the results of the test are defined only in terms of this test method.

18. Keywords

18.1 asphaltene precipitation; asphaltenes; compatibility; crude oil; heavy fuel oil; insolubility number; P-value; residual oil; solubility blending number; solvent equivalent; stability; stability reserve