9. Procedure

9.1 Prepare the instrument for measuring by turning it on at least 1 h before use, and make preparation so that one scan can be run automatically every 60 s for 15 min. For more detailed instructions, see Annex A2 and Annex A3.

9.2 Sample to be placed in an oven at 60°C for 24 h to ensure homogeneity.

9.3 Remove the sample from the oven and shake for 1 min to ensure mixing.

9.4 With the aim to increase and achieve a comparable transmittance for all types of oils, weigh in 5 +/- 0.01 g of the oil sample on a balance. Record the weight of oil added to four decimal places and dilute with toluene, in a weight ratio from 1:3 to 1:20 to have a baseline under 15% of transmittance, for guidance see Annex A1, in a bottle with cap (6.6). Carefully add a magnetic bar to the oil-toluene solution ensuring none of the oil/toluene mixture is lost, and seal the bottle. Shake the jar well until the oil/toluene mixture no longer adheres to the bottom of the jar. Put the bottle on a magnetic stirrer and stir the mixture for 90 +/- 5 min.

9.5 Using a 25 mL burette (6.12), add 23 mL of n-heptane into a glass bottle (6.7). Use a pipette to add 2.0 mL of the oil/toluene mixture prepared in 9.4 to the heptane and shake the mixture briskly for 6 s.

9.6 Use a pipette to transfer 7 mL of the oil-toluene-heptane mixture in a period of less than 10 s into the cylindrical clear glass vial and screw the cap on (6.3), taking care not to deposit material on the tube walls. If 10 s is exceeded, the rest should be stopped and the sample retested.

9.7 Immediately place the cylindrical glass vial, with cap, in the instrument at ambient temperature (20 to 25°C) and start to measure at once.

NOTE 1 - The transmittance through the cylindrical glass vial is now recorded every 60 s for 15 min and stored by the software on the hard disk of the computer.

9.8 When the measurement is finished, remove the glass vial from the optical scanning device and clean the glass vial with toluene in a fume hood.

10. Calculation and Interpretation of Results

10.1 Calculation of Results:

10.1.1 The following calculations may be completed either manually, by using a spreadsheet program (described in Annex A2) or automatically, using the software Heavy Fuel v. 1.0 (described in Annex A3).

10.1.2 Analyze the transmittance between 10 to 55 mm (10 mm from the bottom of the glass vial), that is, calculate the average transmittance (Xi) recorded in this region for each minute.

10.1.3 Calculate the total average transmittance (XT) of each of the 16 scans.

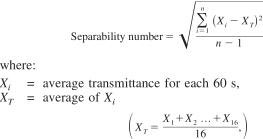

10.1.4 Calculate the separability number using the equation for standard deviation:

and

n = the set of replicate measurements (16 in the method).

10.2 Interpretation ofResults:

10.2.1 The separability number is a rate-related factor that gives a measure of how easily an oil phase separates upon addition of heptane. Phase separation is due to asphaltene flocculation and sedimentation. As asphaltenes fall out of solution, the transmittance through the sample increases. There will be a rapid change in transmittance if this process is quick, resulting in a high separability number. A high number shows that the stability reserve of the oil is poor, while a low number shows that there is a stability reserve in the oil. The separability number is presented in percent transmittance.