14. Report

14.1 Report the following information:

14.1.1 Mass loss of the ring and vanes in milligrams.

14.1.2 Flow rate at start and end of test.

14.1.3 Any unusual observations on wear, scuffing, deposits, cavitation damage, deterioration of seals, and bushing replacement.

14.1.4 List any modifications to the test method procedure, conditions, or apparatus, and report them as Modified Test Method D7043.

15. Precision and Bias

15.1 The precision of this test method is based on an interlaboratory study conducted in 2016. Each of seven laboratories tested three different hydraulic fluids. Every "test result" represents an individual determination, and all participants were instructed to report duplicate test results. Practice D6300 was followed for the design and analysis of the data; the details are given in ASTM Research Report No. RR:D02-1863.

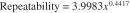

15.1.1 Repeatability (r) - The difference between repetitive results obtained by the same operator in a given laboratory applying the same test method with the same apparatus under constant operating conditions on identical test material within short intervals of time would in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in 20.

15.1.1.1 Repeatability can be interpreted as maximum difference between two results, obtained under repeatability conditions, that is accepted as plausible due to random causes under normal and correct operation of the test method.

where x is the average of two results.

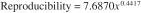

15.1.2 Reproducibility (R) - The difference between two single and independent results obtained by different operators applying the same test method in different laboratories using different apparatus on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following values only in one case in 20.

15.1.2.1 Reproducibility can be interpreted as maximum difference between two results, obtained under reproducibility conditions, that is accepted as plausible due to random causes under normal and correct operation of the test method.

where x is the average of two results.

15.1.3 The above terms (repeatability limit and reproducibility limit) are used as specified in Practice E177.

15.1.4 Note that there were fewer than the required 30 degrees of freedom available for analysis in the calculation of precision for this test method, and the applicability of the results of this study should be assessed accordingly.

15.1.5 Any judgment in accordance with statements 15.1.1 and 15.1.2 would normally have an approximate 95 % probability of being correct, however the precision statistics obtained in this ILS must not be treated as exact mathematical quantities which are applicable to all circumstances and uses. The limited number of materials tested and laboratories reporting results guarantees that there will be times when differences greater than predicted by the ILS results will arise, sometimes with considerably greater or smaller frequency than the 95 % probability limit would imply. The repeatability limit and the reproducibility limit should be considered as general guides, and the associated probability of 95 % as only a rough indicator of what can be expected.

15.2 Bias - At the time of the study, there was no accepted reference material suitable for determining the bias for this test method, therefore no statement on bias is being made.

15.3 The precision statement was determined through statistical examination of 39 results, from seven laboratories, on three hydraulic fluids.

15.4 To judge the equivalency of two test results, it is recommended to choose the fluid closest in characteristics to your test material.

NOTE 27 - The ILS did not meet the minimum sample design nor degree of freedom for reproducibility as required by Practice D6300. The total number of samples is 3, and the df achieved for R is 10.

16. Keywords

16.1 hydraulic fluid; vane pump; wear