14. Report

14.1 Report the following information:

14.1.1 The type and identification of the product tested.

14.1.2 The reference to this test method.

14.1.3 Any deviation, by agreement or otherwise, from the procedure specified.

14.1.4 The test results for the dynamic or kinematic viscosity, or both, to four significant figures, optionally also for the density to three decimal places in g/cm3 or integer in kg/cm3 (example: 0.877 g/cm3 or 877 kg/cm3), together with the test temperature.

14.1.5 Date and time of the test.

14.1.6 Name and address of the test laboratory.

15. Precision and Bias

15.1 Comparison ofResults:

15.1.1 Determinability, (d) - Quantitative measure of the variability associated with the same operator in a given laboratory, obtaining successive determined values using the same apparatus for a series of operations leading to a single result. It is defined as that difference between two such single determined values as would be exceeded in the long run, in only one case in 20, in the normal and correct operation of the test method. (See Table 1.)

15.2 Comparison ofResults:

15.2.1 Repeatability (r) - The difference between successive results obtained by the same operator in the same laboratory with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of this test method, exceed the values indicated only in one case in twenty. (See Table 2.)

15.2.2 Reproducibility (R) - The difference between two single and independent results obtained by different operators working in different laboratories on nominally identical test material would, in the long run, in the normal and correct operation of this test method, exceed the values indicated only in one case in twenty. (See Table 3.)

15.3 Bias - No information can be presented on the bias of the procedure in this test method, because no material having an accepted reference value has been tested.

15.4 Relative Bias - No bias to Test Methods D445 and D4052 was found to exist for base oils (see Appendix X1 and Appendix X2).

15.4.1 Degree ofAgreement between Results by Test Method D7042 and Test Method D445 - Results on the same materials produced by Test Method D7042 and Test Method D445 have been assessed in accordance with procedures outlined in Practice D6708. The findings are:

15.4.2 For formulated oils, RR:D02-1741 suggests a bias correction of:

Y-Estimate = 0.996 X at 40 °C

Y-Estimate = X - 2.3538e - 02 at 100 °C

where:

Y-Estimate = estimated D445 result using D7042 result.

Bias-corrected kinematic viscosity results from Test Method D7042, as per the bias correction equation that follows, may be considered as practically equivalent to results from Test Method D445, for sample types and property ranges studied. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials studied.

bias-corrected X (predicted Y) = mX + b;

m = 0.996;

b = 0 at 40 °C

and

bias-corrected X (predicted Y) = mX + b;

m = 1;

b = -2.3538e - 02 at 100 °C

where:

X = result obtained by Test Method D7042, and bias-corrected X = predicted Y result that would have been obtained by Test Method D445 on the same sample.

Differences between bias-corrected results from Test Method D7042 and Test Method D445, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. The RXY at 40 mm2/s was found to be 0.52156 mm2/s at 40 °C and RXY at 10 mm2/s was found to be 0.08819 mm2/s at 100 °C.

15.4.3 For diesel fuels, RR:D02-1742 suggests a bias correction of:

Y-Estimate = 0.9872X - 0.00015 at 40 °C

where:

Y-Estimate = estimated D445 result using D7042 result.

Bias-corrected kinematic viscosity results from Test Method D7042, as per the bias correction equation that follows, may be considered as practically equivalent to results from Test Method D445, for sample types and property ranges studied. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction, for the materials studied.

bias-corrected X (predicted Y) = mX + b;

m = 0.9872;

b = -0.00015

where:

X = result obtained by Test Method D7042, and

bias-corrected X = predicted Y result that would have been obtained by Test Method D445 on the same sample.

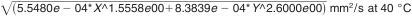

Differences between bias-corrected results from Test Method D7042 and Test Method D445, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. The RXY at 2 mm2/s was found to be:

15.4.4 For jet fuel at -20 °C, RR:D02-1750 has determined relative bias as follows:

Bias-corrected kinematic viscosity results from Test Method D7042, as per the bias correction equation that follows, may be considered as practically equivalent to results from Test Method D445, for sample types and property ranges studied. No sample-specific bias, as defined in Practice D6708, was observed after the bias-correction for the materials studied.

bias-corrected X (predicted Y) = mX + b; m = 1; b = -0.013373

where:

X = result obtained by Test Method D7042, and

bias-corrected X = predicted Y result that would have been obtained by Test Method D445 on the same sample.

Differences between results from Test Method D7042 and Test Method D445, for the sample types and property ranges studied, are expected to exceed the following between methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time. RXY = 0.162 mm2/s at -20 °C.

15.4.5 For Biodiesel and Biodiesel blend fuels at 40 °C, RR:D02-1776 has determined relative bias as follows:

Degree ofAgreement between kinematic viscosity results by Test Method D7042 and Test Method D445 (manual method) - Results on the same materials produced by Test Method D7042 and Test Method D445 (manual method) have been assessed in accordance with procedures outlined in Practice D6708. The findings are:

D6708 Outcome: A3

Bias-corrected kinematic viscosity results from Test Method D7042, as per the bias correction equation that follows, may be considered as practically equivalent to kinematic viscosity results from Test Method D445 (manual method), for sample types and property ranges studied. No sample-specific bias, as defined in Practice D6708, was observed after the biascorrection, for the materials studied.

bias-corrected X (predicted Y) = 0.992X + 0.022

where:

X = result obtained by Test Method D445 (manual), and

bias-corrected X = predicted Y result that would have been obtained by Test Method D445 (manual method) on the same sample.

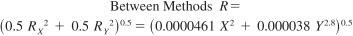

Differences between bias-corrected kinematic viscosity results from Test Method D7042 and Test Method D445 (manual method), for the sample types and property ranges studied, are expected to exceed the following between-methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time:

where:

RX = reproducibility of D7042 as determined from ILS #895, and

RY = reproducibility of D445 (manual method) as determined from ILS #895.

15.4.6 For residual fuel oils at 50 °C, RR:D02-1837 has determined that no bias correction is required and no sample specific biases were identified. For residual fuel oil at 100 °C, RR:D02-1837 has determined a bias correction of 0.251 mm2/s while no sample specific biases were identified.

Bias-corrected X (predicted Y) = 1X + 0.251 mm2/s

Differences between bias-corrected kinematic viscosity results from Test Method D7042 and Test Method D445 (manual method), for the sample types and property ranges studied, are expected to exceed the following between-methods reproducibility (RXY), as defined in Practice D6708, about 5 % of the time:

Between-methods RXY = (0.5 RX2 + 0.5 RY2)0.5

where:

RX = reproducibility of D7042 as determined from ILS #1003, and

RY = reproducibility of D445 (manual method) as determined from ILS #1003.

15.5 Interlaboratory Study - Precision values for base oils were obtained by statistical examination of interlaboratory results obtained by twelve laboratories from ten mineral oils (base oils without additive package) in the dynamic viscosity range from 2.05 mPa·s to 456 mPa·s at 40 °C and from 0.83 mPa·s to 31.6 mPa·s at 100 °C and in the density range from 0.82 g/cm3 to 0.92 g/cm3 at 15 °C. Density results at 15 °C were calculated by linear extrapolation from the results obtained at 40 °C and 100 °C. The number of replicates was two, obtained in the shortest possible time interval, typically 10 min, using the standard procedure described in 11.1.

15.5.1 Precision values for base oils were first published in 2003.

NOTE 4 - Base oil precision values were determined on instruments using manual sample introduction only.

15.5.2 Precision values for formulated oils (commercially available formulated oils like motor oils, hydraulic oils, and synthetic gear oils) were obtained by statistical examination of interlaboratory results as follows:

15.5.2.1 The dynamic viscosity range from 34 mPa·s to 411 mPa·s at 40 °C from 10 formulated oils by 19 laboratories and from 5.24 mPa·s to 39.2 mPa·s at 100 °C from 10 formulated oils by 18 laboratories.

15.5.2.2 The kinematic viscosity range from 40.164 mm2/s to 150.71 mm2/s at 40 °C from 9 formulated oils by 19 laboratories and from 6.4682 mm2/s to 48.292 mm2/s at 100 °C from 10 formulated oils by 18 laboratories.

15.5.2.3 The density range from 0.82989 g/cm3 to 0.87300 g/cm3 at 40 °C from 10 formulated oils by 20 laboratories and from 0.79192 g/cm3 to 0.83512 g/cm3 at 100 °C from 10 formulated oils by 19 laboratories.

15.5.2.4 Precision values for formulated oils were first published in 2012.

15.5.3 Precision values for diesel fuels were obtained by statistical examination ofinterlaboratory results obtained by 18 laboratories from eight diesel fuel grades (#1, #2, and #4 diesel fuels according to Specification D975) in the dynamic viscosity range from 1 mPa·s to 6 mPa·s at 40 °C (kinematic viscosity range from 1.6477 mm2/s to 7.2315 mm2/s at 40 °C) and ten diesel fuel grades (#1, #2, and #4 diesel fuels according to Specification D975) in the density range from 0.76920 g/cm3 to 0.89174 g/cm3 at 40 °C.

15.5.3.1 Precision values for diesel fuels were first published in 2012.

15.5.4 Precision values for jet fuel at -20 °C were obtained by statistical examination of interlaboratory results obtained by:

13 laboratories from 12 jet fuel grades (Jet-A, Jet-A1, JP8, SPK, SPK blend, and N2B viscosity standard) in the dynamic viscosity range from 3.1705 mPa·s to 6.7489 mPa·s at -20 °C.

13 laboratories from 12 jet fuel grades (Jet-A, Jet-A1, JP8, SPK, SPK blend and N2B viscosity standard) in the kinematic viscosity range from 3.8087 mm2/s to 7.9824 mm2/s at -20 °C.

13 laboratories from 12 jet fuel grades (Jet-A, Jet-A1, JP8, SPK, SPK blend and N2B viscosity standard) in the density range from 0.78672 g/cm 3 to 0. 85998 g/cm3 at -20 °C. The degrees of freedom associated with the reproducibility estimate from this round robin study are 18. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

15.5.4.1 Precision values for jet fuel at -20 °C were first published in 2012.

15.5.5 Precision values for Biodiesel and Biodiesel blend fuels at 40 °C were obtained by statistical examination of interlaboratory results obtained by:

13 laboratories from 12 biodiesel and biodiesel blend fuels and one synthetic viscosity standard (B100, B6, B10 and B20 from varying feedstock and meeting the specifications of D6751 and D7467) representing a dynamic viscosity range from 1.9818 mPa.S to 4.4196 mPa.S and a kinematic viscosity range from 2.404 mm2/S to 5.0767 mm2/S.

17 laboratories from 12 biodiesel and biodiesel blend fuels and one synthetic viscosity standard (B100, B6, B10 and B20 from varying feedstock and meeting the specifications of D6751 and D7467) representing a density range from 0.8237 g/cm 3 to 0.8704 g/cm3.

NOTE 5 - The degrees of freedom associated with the reproducibility estimate for density is 19. Since the minimum requirement of 30 (in accordance with Practice D6300) is not met, users are cautioned that the actual reproducibility may be significantly different than these estimates.

15.5.5.1 Precision values for biodiesel and biodiesel blend fuels at 40 °C were first published in 2014.

15.5.6 Precision values for residual fuel oils at 50 °C and 100 °C were obtained by statistical examination of interlaboratory results obtained by 10 laboratories from 10 residual fuel samples conforming to D396 Grades No. 5 or 6 and/or ISO 8217 RMG and RMK representing a dynamic viscosity range from 25.31 mPa.s to 2212 mPa.s at 50 °C and 5.493 mPa.s to 109.1 mPa.s at 100 °C.

15.5.6.1 The kinematic viscosity range spanned 27.6 mm2/s to 2230 mm2/s at 50 °C and 6.202 mm2/s to 108.1 mm2/s at 100 °C.

15.5.6.2 The density range spanned 0.09173 g/cm3 to 0.9937 g/cm3 at °C and 0.8831 g/cm3 to 0.9611 g/cm3 at 100 °C.

15.5.7 The interlaboratory studies were performed according to Practices D6300 and D6708. For the determination of the relative bias the samples were also tested by kinematic viscometers according to Test Method D445 and for base oils by digital density meters according to Test Method D4052 in the same laboratories.

16. Keywords

16.1 density; dynamic viscosity; kinematic viscosity; Stabinger viscometer; viscosity; viscosity index