7. Apparatus

7.1 Pyrolysis Furnace, a furnace capable of maintaining a temperature sufficient to volatilize and combust all of the sample and oxidize the sulfur to SO2. The furnace temperatures for petroleum substances shall be as recommended by the manufacturer.

7.2 Quartz Combustion Tube, capable of withstanding 900 to 1200°C. The inlet end of the tube holds a septum for syringe entry of the sample and has inlet fittings or side arms for the introduction of oxygen (O2) and inert gas. The construction is such that the inert gas (or inert gas and oxygen mixture) sweeps the inlet zone transporting all of the volatilized sample into a high temperature oxidation zone. The oxidation section shall be large enough to ensure complete oxidation of the sample.

7.3 Drier Tube - The reaction products include water vapor that must be removed prior to measurement by the electrochemical detector. This can be accomplished with a magnesium perchlorate scrubber or a membrane drying tube (permeation drier), or both.

7.4 Electrochemical Detector, capable of measuring SO2 in the combustion gas stream.

7.5 Data Reduction System, having the capability of measuring, amplifying, and integrating the current from the electrochemical detector. The amplified or integrated output signal shall be applied to a digital display or some other data reporting device.

7.6 Microlitre Syringe, of 5, 10, 25, 50, or 100 µL capacity capable of accurately delivering microlitre quantities is required. The needle should be long enough to reach the hottest portion of the inlet section of the furnace when injecting the sample.

7.7 Recorder (Optional).

7.8 Constant Rate Injector or Automatic Sampler System(s) (Optional), capable of delivering a sample at a precisely controlled rate.

8. Reagents

8.1 Purity of Chemicals - Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents shall conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

8.2 Magnesium Perchlorate, Mg(ClO4)2 - (Warning - Magnesium perchlorate is a strong oxidizer, and is an irritant) for drying products of the combustion (if a permeation drier is not used).

8.3 Inert Gas - Either argon (Ar) or helium (He) may be used. The purity should be no less than 99.99 mol %.

8.4 Oxygen - The purity should be no less than 99.99 mol % (Warning - Oxygen of this purity will vigorously accelerate combustion).

8.5 Solvent - The solvent chosen should be capable of dissolving the sulfur-containing compound used to prepare the standard and, if necessary, the samples. The solvent of choice should have a boiling point similar to the samples being analyzed and it should contain less sulfur than is in the lowest sample to be analyzed. Suggested possibilities include, but are not limited to: toluene, iso-octane, methanol, cetane, or other solvent similar to the compound present in the sample to be analyzed (Warning - Flammable solvents).

NOTE 2 - A quick screening can be conducted by injecting the solvent and sample once or twice and comparing relative integral response.

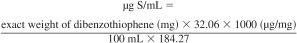

8.6 Sulfur Stock Solution, 1000 µg S/mL - Prepare a stock solution by accurately weighing to the nearest 0.1 mg, 0.576 g of dibenzothiophene into a tared 100-mL volumetric flask. Dilute to volume with selected solvent. This stock may be further diluted to desired sulfur concentrations.

NOTE 3 - Dibenzothiophene may be used for calibration throughout the boiling range of this test method.

8.7 Dibenzothiophene (C12H8S), CAS 132650 - (Warning - Dibenzothiophene is an irritant) molecular weight 184.27, purity >99.8 %.

8.8 Sulfur Working Standard Solutions, 0.5, 1.0, 10.0, and 100.0 µg S/mL - The working standards are prepared by accurately pipetting and diluting each to volume with solvent. To obtain the following concentrations 100.0, 10.0, 1.0, and 0.5 µg S/mL see Table 1.

NOTE 4 - Working standards should be prepared fresh on a regular basis, depending upon frequency of use and age.