9. Procedure

9.1 Carefully place 1 kg of the steel balls and 100 g +/- 0.5 g of the 4 mm to 8 mm fraction of the sieved test sample in each grinding vessel and close the lid. Record the weight to the nearest 0.1 g. Attach the vessels to the vibration mill.

9.2 Turn the mill on and grind the sample for 3.5 min +/- 2 s as measured by the timer switch.

9.3 Carefully empty the contents of one vessel on to an 8 mm sieve, placed on top of a 4 mm sieve. Screen by hand, using approximately 60 horizontal movements in about half a minute. The steel balls will remain on the 8 mm sieve, and part of the granular material will remain on the 4 mm sieve.

9.4 Weigh the portion of granular material that remains on the 4 mm sieve to the nearest 0.01 g and record as vessel 1, m3.

9.5 Repeat with the contents of the other vessel and record as vessel 2, m4.

10. Calculation

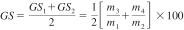

10.1 The grain stability (GS) of the calcined petroleum coke, expressed in percent, is given by the equation:

where:

GS1 = grain stability for vessel 1 in %,

GS2 = grain stability for vessel 2 in %,

m1 = mass of test sample placed in vessel 1, g,

m2 = mass of test sample placed in vessel 2, g,

m3 = mass of test sample from vessel 1 retained on the 4 mm sieve, g, and

m4 = mass of test sample from vessel 2 retained on the 4 mm sieve, g.

10.2 If GS 1 and GS 2 differ by less than √2 x the repeatability of the test method, report the result, GS, as the mean of the simultaneous duplicate determinations GS1 and GS2 , to the nearest 0.01 %.

10.3 If GS 1 and GS 2 differ by more than √2 x the repeatability of the test method, repeat the procedure detailed in Section 10. Reject all the results.