ASTM D6730 Standard Test Method for Determination of Individual Components in Spark Ignition Engine Fuels by 100-Metre Capillary (with Precolumn) High-Resolution Gas Chromatography

6. Apparatus

6.1 Gas Chromatograph - Instrumentation capable of column oven temperature programming, from subambient (5°C) to at least 200°C, in 0.1°C/min or less rate increments, is required. Multi-step column oven temperature programming is required, consisting of an initial hold time, an initial temperature program followed by an isothermal temperature hold and another programmed temperature rise. A heated flash vaporizing injector designed to provide a linear sample split injection (that is, 200:1) is required for proper sample introduction. The associated carrier gas controls must be of sufficient precision to provide reproducible column flows and split ratios in order to maintain analytical integrity. A hydrogen flame ionization detector, with associated gas controls and electronics, designed for optimum response with open tubular columns, shall conform to the specifications as described in Practice E 594, as well as having an operating temperature range of up to at least 250°C.

6.2 Sample Introduction - Manual or automatic liquid sample injection to the splitting injector may be employed. Automated injections are highly recommended. Micro-syringes, auto-syringe samplers, or valves capable of 0.1 to 0.5 µL. injections are suitable. It should be noted that some syringes and improper injection techniques as well as inadequate splitter design could result in sample fractionation. This must be determined in accordance with Section 10.

6.3 Electronic Integrator - Any electronic integration device used for quantitating these analyses shall meet or exceed these minimum requirements:

6.3.1 Capacity to handle 400 or more peaks per analysis.

6.3.2 Normalized area percent calculation with response factors.

6.3.3 Noise and spike rejection.

6.3.4 Accurate area determination of fast (1 to 2 s) peaks (10 Hz or greater sampling rate).

6.3.5 Maintain peak detection sensitivity for narrow and broad peaks.

6.3.6 Positive and negative sloping baseline correction.

6.3.7 Perpendicular drop and tangent skimming as needed.

6.3.8 Display of baseline used to ensure correct peak area determination.

6.4 Open Tubular Column - The column used for this test method consists of a primary (100 m) analytical column and a precolumn. The ability to provide the required component separations is dependent on the precise control of the column selectivity, which is typically slightly more than that exhibited by current commercially available columns. Some older columns, and columns that have a sample residue from repeated use without conditioning, may exhibit the required polarity. Until adequate columns are commercially available, the currently used methyl silicone columns can be modified or tuned to meet the method column specifications. See Section 11 for a description of the column performance specifications and Annex A1 for a description of the column modification procedure.

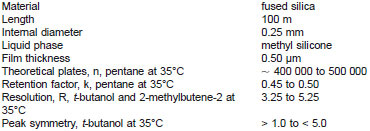

6.4.1 The primary gas chromatographic column used for this test method will meet the following specifications.

6.4.2 Precolumn - A variable length (1 to 4 m) of 5 % phenyl/95 % dimethylpolysiloxane fused silica open tubular column (0.25 mm inside diameter) is added to the front (injector) end of the 100 m column, as described in Annex A1.

7. Reagents and Materials

7.1 Carrier Gas - Helium, 99.999 % pure. (Warning - Helium, air, nitrogen, compressed gas under pressure.)

7.2 Oxidant - Air, 99.999 % pure. (Warning - see 7.1.)

7.3 Detector Makeup Gas - Nitrogen, 99.999 % pure. (Warning - see 7.1.)

7.4 Fuel Gas - Hydrogen, 99.999 % pure. (Warning - Hydrogen, flammable gas under high pressure.)

7.5 Reference Standards:

7.5.1 Purity of Reagents - Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents conform to the specifications of the Committee on Analytical Reagents of the American Chemical Society where such specifications are available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use without lessening the accuracy of the determination.

7.5.2 Methanol - (Warning - These materials are flammable and may be harmful or fatal, if ingested or inhaled.).

7.5.3 Ethanol - Only absolute ethanol of 99.5 minimum percent meets the requirements of this test method. (Warning - see 7.5.2.)

7.5.4 Hydrocarbon and Other Component References - Individual and mixed component reference materials are commercially available and may be used to establish qualitative and quantitative calibration. (Warning - see 7.5.2.)

7.5.5 System and Column Evaluation Mixture - A quantitatively prepared mixture, complying with Practice D4307, of individual hydrocarbons and oxygenates of interest is used for system and column evaluation (see Table 1). (Warning - see 7.5.2.) Fig. 1 is a chromatogram of the recommended mixture in Table 1.

8. Sampling

8.1 Hydrocarbon liquids with Reid vapor pressures of 110 kPa (16 psi) or less may be sampled either into a floating piston cylinder or into an open container (Practices D4057 and D4177). If the sample as received does not meet the upper boiling range requirements of 1.1, it may be necessary to extend the analysis time and raise the upper column temperature of this test method to ensure complete elution of higher boiling range sample material from the column.

8.1.1 Piston Cylinder Sampling - Refer to Practice D3700 for instructions on transferring a representative sample of a hydrocarbon fluid from a source into a floating piston cylinder. Add inert gas to the ballast side of the floating piston cylinder to achieve a pressure of 350 kPa (45 psi) above the vapor pressure of the sample.

8.1.2 Open Container Sampling - Refer to Practice D4057 for instructions on manual sampling from bulk storage into open containers. Stopper the container immediately after taking a sample.

8.2 Preserve the sample by cooling to approximately 4°C and maintaining that temperature prior to analysis.

8.3 Transfer an aliquot of the cooled sample to a precooled septum vial and seal immediately.

8.4 Obtain the test specimen for analysis directly from the sealed septum vial, for either manual or automatic injection.