ASTM D6593 standard test method for Evaluation of Automotive Engine Oils for Inhibition of Deposit Formation in a Spark-Ignition Internal Combustion Engine Fueled with Gasoline and Operated Under Low-Temperature, Light-Duty Conditions

1. Scope

1.1 This test method is commonly referred to as the Sequence VG test and has been correlated with vehicles used in stop-and-go service prior to 1996, particularly with regard to sludge and varnish formation. It is one of the test methods required to evaluate oils intended to satisfy the API SL performance category.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in 7.7, 7.10.2.2, 8.3.4.2, 8.4.4.3, 9.2.6, 9.3.4.5, 12.1.1.7, 12.2.1.4, and Annex A1.

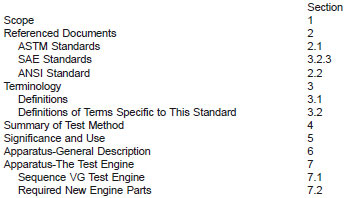

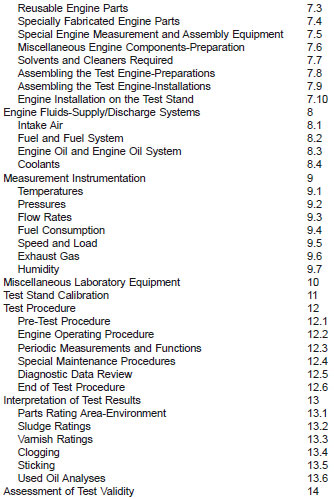

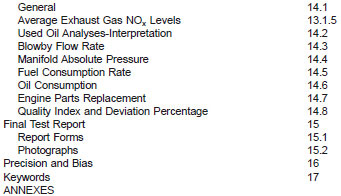

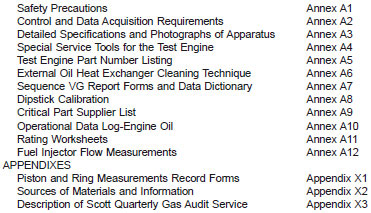

1.4 A Table of Contents follows:

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products at Atmospheric Pressure

D287 Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)

D323 Test Method for Vapor Pressure of Petroleum Products (Reid Method)

D381 Test Method for Gum Content in Fuels by Jet Evaporation

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (the Calculation of Dynamic Viscosity)

D525 Test Method for Oxidation Stability of Gasoline (Induction Period Method)

D873 Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D1298 Test Method for Density, Relative Density (Specific Gravity) or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

D2622 Test Method for Sulfur in Petroleum Products by Wavelength Dispersive X-ray Fluorescence Spectrometry

D2789 Test Method for Hydrocarbon Types in Low Olefinic Gasoline by Mass Spectrometry

D3237 Test Method for Lead in Gasoline by Atomic Absorption Spectrometry

D3525 Test Method for Gasoline Diluent in Used Gasoline Engine Oils by Gas Chromatography

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D4294 Test Method for Sulfur in Petroleum and Petroleum Products by Energy-Dispersive X-ray Fluorescence Spectrometry

D4485 Specification for Performance of Engine Oils

D4863 Test Method for Determination of Lubricity of Two-Stroke-Cycle Gasoline Engine Lubricants

D5059 Test Method for Lead in Gasoline by X-Ray Spectroscopy

D5185 Test Method for Determination of Additive Elements, Wear Metals, and Contaminants in Used Lubricating Oils and Determination of Selected Elements in Base Oils by Inductively Coupled Plasma Atomic Emissions Spectrometry (ICP-AES)

D5302 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Deposit Formation and Wear in a Spark-Ignition Internal Combustion Engine Fueled with Gasoline and Operated Under Low-Temperature, Light-Duty Conditions

D5844 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Rusting (Sequence IID)

D5862 Test Method for Evaluation of Engine Oils in Two-Stroke Cycle Turbo-Supercharged 6V92TA Diesel Engine

D6304 Test Method for Determination of Water in Petroleum Products, Lubricating Oils, and Additives by Coulometric Karl Fischer Titration

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

G 40 Terminology Relating to Erosion and Wear

2.2 ANSI Standard:

ANSI MC96.1 Temperature Measurement-Thermocouples

3. Terminology

3.1 Definitions:

3.1.1 air-fuel ratio, n - in internal combustion engines, the mass ratio of air-to-fuel in the mixture being inducted into the combustion chambers.

3.1.1.1 Discussion - In this test method, air-fuel ratio (AFR), is controlled by the EEC IV engine control module.

3.1.2 blowby, n - in internal combustion engines, the combustion products and unburned air and fuel mixture that enter the crankcase.

3.1.3 cold-stuck piston ring, n - in internal combustion engines, a piston ring that is stuck when the piston and ring are at room temperature, but inspection shows that it was free during engine operation.

3.1.3.1 Discussion - A cold-stuck piston ring cannot be moved with moderate finger pressure. It is characterized by a polished face over its entire circumference, indicating essentially no blowby passed over the ring face during engine operation.

3.1.4 debris, n - in internal combustion engines, solid contaminant materials unintentionally introduced into the engine or resulting from wear.

3.1.4.1 Discussion - Examples include such things as gasket material, silicone sealer, towel threads, and metal particles.

3.1.5 hot-stuck piston ring, n - in internal combustion engines, a piston ring that is stuck when the piston and ring are at room temperature, and inspection shows that it was stuck during engine operation.

3.1.5.1 Discussion - The portion of the ring that is stuck cannot be moved with moderate finger pressure. A hot-stuck piston ring is characterized by varnish or carbon across some portion of its face, indicating that portion of the ring was not contacting the cylinder wall during engine operation.

3.1.6 filtering, n - in data acquisition, a means of attenuating signals in a given frequency range. They can be mechanical (volume tank, spring, mass) or electrical (capacitance, inductance) or digital (mathematical formulas), or a combination thereof. Typically, a low-pass filter attenuates the unwanted high frequency noise.

3.1.7 knock, n - in a spark ignition engine, abnormal combustion, often producing audible sound, caused by autoignition of the air/fuel mixture.

3.1.8 out of specification data, n - in data acquisition, sampled value of a monitored test parameter that has deviated beyond the procedural limits

3.1.9 reading, n - in data acquisition, the reduction of data points that represent the operating conditions observed in the time period as defined in the test procedure.

3.1.10 scoring, n - in tribology, a severe form of wear characterized by the formation of extensive grooves and scratches in the direction of sliding.

3.1.11 scuffing, n - in lubrication, damage caused by instantaneous localized welding between surfaces in relative motion that does not result in immobilization of the parts.

3.1.12 sludge, n - in internal combustion engines, a deposit, principally composed of insoluble resins and oxidation products from fuel combustion and the lubricant, that does not drain from engine parts but can be removed by wiping with a cloth.

3.1.13 time constant, n - in data acquisition, A value which represents a measure of the time response of a system. For a first order system responding to a step change input, it is the time required for the output to reach 63.2 % of its final value.

3.1.14 varnish, n - in internal combustion engines, a hard, dry, generally lustrous deposit that can be removed by solvents but not by wiping with a cloth.

3.1.15 wear, n - loss of material from, or relocation of material on, a surface.

3.1.15.1 Discussion - Wear generally occurs between two surfaces moving relative to each other, and is the result of mechanical or chemical action or by a combination of mechanical and chemical actions.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 clogging, n - the restriction of a flow path due to the accumulation of material along the flow path boundaries.

3.2.2 enrichment, n - in internal combustion engine operation, a fuel consumption rate in excess of that which would achieve a stoichiometric air-to-fuel ratio.

3.2.2.1 Discussion - Enrichment is usually indicated by elevated CO levels and can also be detected with an extended range air/fuel ratio sensor.

3.2.3 Lambda, n - the ratio of actual air mass induced, during engine operation, divided by the theoretical air mass requirement at the stoichiometric air-fuel ratio for the given fuel.

3.2.3.1 Discussion - A Lambda value of 1.0 denotes a stoichiometric air-fuel ratio.

3.2.4 low-temperature, light-duty conditions, n - indicative of engine oil and coolant temperatures that average below normal warmed-up temperatures, and engine speeds and power outputs that average below those encountered in typical highway driving.

3.2.5 ramping, n - the prescribed rate of change of a variable when one set of operating conditions is changed to another set of operating conditions.