ASTM D6550 Standard Test Method for Determination of Olefin Content of Gasolines by Supercritical-Fluid Chromatography

8. Preparation of Apparatus

8.1 Install the SFC instrumentation in accordance with the manufacturer's instructions. System operating conditions will depend on the column used and optimization of performance. The conditions listed in Table 1 have been used successfully. If the performance characteristics in terms of retention and resolution, specified in 8.2, are not achieved, the temperature, pressure, or mobile-phase flow rate can be modified to achieve compliance. A silica column of low activity can be reactivated by solvent rinsing, using accepted liquid-chromatographic activation strategies.

8.2 System Performance:

8.2.1 System Optimization - The operation of the SFC system shall be optimized in order to achieve the required separation on the silica column. This process is different if an optional UV detector is available.

8.2.1.1 When the optional UV detector is installed, the separation between the three different classes of compounds can be monitored directly. Saturates show no UV absorption. Olefins show significant absorption at wavelengths up to about 220 nm but no absorption at 250 nm or higher. Aromatics show considerable absorption at low wavelengths, extended to a wavelength of 250 nm and higher. The onset of the elution of the olefin fraction (following the saturates fraction) can be monitored at 220 nm. The elution of the aromatic fraction can be monitored at 250 nm. In this case, the performance mixture (see 7.6) can be used to optimize the separation of the olefins and aromatics.

8.2.1.2 Without a UV detector being installed, individual pure components and the performance mixture (see 7.6) can be used to optimize the system.

8.2.2 Column Requirements:

8.2.2.1 Silica Column - The critical requirement for the silica column is its ability to achieve a quantitative separation between the olefins and aromatics. The performance of this column can be verified independently of that of the silver-loaded column by switching the valves to the appropriate position (see 6.1.7.4).

8.2.2.1.1 When using a UV detector, the requirement is baseline resolution between the olefin and aromatic signals. The resulting switching time (see Section 9) shall be chosen to occur just before the onset of the aromatics signal.

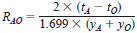

8.2.2.1.2 When using only an FID, the resolution (RAO) between the olefinic compound and the aromatic compound in the performance mixture shall be at least three when measured as follows:

where:

tA = retention time for the aromatic reference compound, s,

tO = retention time for the olefinic reference compound, s,

yA = peak width at half height for the aromatic reference compound, s, and

yO = peak width at half height for the olefinic reference compound, s.

8.2.2.2 All aromatic compounds, as well as oxygenates and other polar molecules, are eluted from the silica column in the backflush mode during a time, tAR, which shall be less than five times the loading time, tL. The elution of the aromatics and polars can be observed using an FID. Complete elution is thought to have occurred if the detector value (SEnd) has returned to the baseline value observed before the elution of any peaks (SBaseline) to within 0.1 % of the height of the aromatics peak (hAromatics), that is,

SEnd ≤ SBaseline + hAromatics/1000

8.2.2.3 Silver-loaded Column - This column is operated exclusively as an olefin trap. Its stability and chromatographic efficiency are not critical as long as the following two requirements are met. The column shall allow a quantitative separation between the saturates and the olefins and the quantitative release of all olefins under appropriate conditions. The performance of the silver-loaded column can be verified independently of that of the silica column by switching the valves to the appropriate position (see 6.1.7.3).

NOTE 5 - It is recommended that aromatic solutes should not be introduced on the silver-loaded column. This can be achieved by using a loading-time mixture, which does not contain aromatics, or by using the silica column to trap the latter.

(a) When using a quality control sample for optimization, as will typically be the case when a UV detector is installed, no oleflns shall elute from the silver-loaded column in the forward-flush mode in a time, tL, defined as:

tL = tSAT + 3 x ySAT

where:

tSAT = time for the saturated-peak apex, s, and

ySAT = peak width at half height of the saturates peak, s.

(b) When using a performance mixture for optimization, as will typically be the case when using only an FID detector, no olefins shall elute from the silver-loaded column in the forward-flush mode in a time, tL, defined as:

tL = tS + 5 x yS

where:

tS = retention time for the saturates reference compound, s, and

yS = peak width at half height for the saturates reference compound, s.

(c) All olefins shall be released from the silver-loaded column in the backflush mode within a time, tBF, that is less than five times the total time during which the olefins are loaded onto the column in the forward-flush mode (tFF), that is,

tBF ≤ 5 x tFF

The total time tFF is the sum of the loading time (tL) and a cleaning time (tC):

tFF = tL + tC

During the time tC, any non-olefinic (saturates or cyclic) compounds that have remained in the olefin trap are eluted in the forward-flush mode. The absence of an FID signal at the end of the time tC confirms proper separation between saturated (including cyclic) and olefinic compounds. The elution of the olefins can be observed using either a UV-absorbance detector set at 220 nm or an FID. Complete elution is thought to have occurred if the detector value (SEnd) has returned to the baseline value observed before the elution of the saturates or olefins (SBaseline), or both, to within 0.1 % of the height of the olefins peak (hOlefins), that is,

SEnd ≤ SBaseline + hOlefins/1000

NOTE 6 - It may be necessary to change the operating conditions in order to meet the requirement of Eq 5. Increasing the mobile-phase density or the column temperature may facilitate the elution of the olefins. However, the best precision can be achieved if the conditions are kept constant.

8.2.3 Retention-time Precision:

8.2.3.1 Repeatability - The repeatability of the retention times has a direct influence on the precision of the total olefin content determined because column switching is performed on a time basis (see Section 9). Retention times obtained for performance mixtures and standard gasolines on a given instrument and column set shall be repeatable within 0.5 % (relative) over a period of several days.

NOTE 7 - It has been observed that the first analysis after an idle period often results in somewhat different retention times than those previously determined for the test method.

8.2.3.2 Reproducibility - The reproducibility of the retention times from column to column and from instrument to instrument is not critical, provided that the column performance requirements (see 8.2) are met.

8.2.4 Calibration Curve:

8.2.4.1 A calibration curve shall be generated by blending at least four different calibration solutions of known olefin content. Olefin-free gasoline blending components and aromatics shall be used to dilute a known olefin mixture to produce standards. A mixture of alkylate, toluene, xylenes, and appropriate oxygenates (MTBE, and so forth) shall be used to prepare calibration solutions. These calibration solutions shall be of known density (see 9.1)

8.2.4.2 These calibration standards shall be blended to cover the entire range of olefin content for which the test method will be used. The calibration curve is a plot of the observed peak area for the entire olefin signal against the known mass percentage of olefins in the calibration standards. Analysis of a blank shall also be used to confirm no olefin contamination in the hydrocarbon mixture used to prepare the standards.

8.2.4.3 The intercept of the calibration curve (extrapolated peak area to zero olefin concentration) shall not be statistically different from zero.

NOTE 8 - If the intercept of the calibration curve is not zero, then one of the materials (alkylate, reformate, and so forth) used to blend the standards may not be olefin free. These shall be analyzed individually to determine which is contaminated.