ASTM D6379 Standard Test Method for Determination of Aromatic Hydrocarbon Types in Aviation Fuels and Petroleum Distillates - High Performance Liquid Chromatography Method with Refractive Index Detection

10. Procedure

10.1 Calibration:

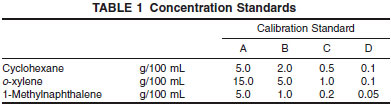

10.1.1 Prepare four calibration standards (A, B, C, and D), in accordance with the concentrations given in Table 1, by weighing, to the nearest 0.0001 g, the appropriate materials into 100 mL volumetric flasks and making up to the mark with heptane.

NOTE 14 - The recommended concentrations in Table 1 will cover most petroleum materials distilling in the kerosine boiling range. Other standard concentrations may be used provided they meet the requirements of the test method (that is, linearity, detector sensitivity, and column resolution).

NOTE 15 - The calibration standard solutions should be stored in tightly stoppered bottles (for example, 100 mL volumetric flasks) in a dark place between 5 and 25°C. Under these conditions, the solutions are viable for at least six months.

10.1.2 When operating conditions are steady (see 9.4), inject 10 µL of Calibration Standard A. Record the chromatogram, and measure the peak areas for each aromatic standard. Ensure that baseline separation is obtained between all three components.

10.1.3 Repeat 10.1.2 using Calibration Standards B, C, and D.

10.1.4 Plot percent m/v (g/100 mL) concentration against area counts for each aromatic standard, that is, o-xylene and 1-methylnaphthalene. Calibration plots should be linear with a correlation coefficient greater than 0.999 and an intercept of less than more or less 0.01. A computer or data system may be used to interpret these calibrations.

NOTE 16 - It should only be necessary to calibrate the refractive index detector on a daily basis.

NOTE 17 - It is recommended that a reference kerosine or one of the four calibration standards be run after every five samples to check the stability of the system.

NOTE 18 - To determine % (V/V) aromatic hydrocarbon types, establish % (V/V) calibration plots (mL/100 mL versus peak area) in place of % (m/V) calibration plots (g/100 mL versus peak area). Divide the % (m/V) concentrations of o-xylene and 1-methylnaphthalene by their respective densities at 20°C to convert to % (V/V) (mL/100 mL). See also Note 19 and Note 22.

10.2 Analysis of Samples:

10.2.1 Weigh, to the nearest 0.001 g, between 4.9 and 5.1 g of test portion into a 10 mL volumetric flask, and make up to the mark with heptane. Shake thoroughly to mix. Allow solution to stand for 10 min and filter (see 6.3), if necessary, to remove insoluble material.

10.2.1.1 For products in which the concentration of one or more aromatic hydrocarbon types fall outside the calibration range, prepare a more concentrated (for example, 10 g/10 mL) or more dilute (2 g/10 mL) test portion solution as appropriate.

NOTE 19 - To determine % (V/V) aromatic hydrocarbon types, prepare a V/V dilution of the test portion by either (1) accurately pipetting 5 mL of test portion into a 10 mL volumetric flask and making up to the mark with heptane, or (2) dividing the test portion weight by its density determined using Test Method D4052 to convert to a volume. See also Note 18 and Note 22.

10.2.2 When operating conditions are steady (see 9.4) and identical to those used for obtaining the calibration data (see 10.1), inject 10 µL of the test portion solution (see 10.2.1) and start data collection.

10.2.3 With reference to Fig. 1, devise a suitable method to find and identify correctly the MAHs and DAHs. Fig. 1 shows a typical chromatogram for an aviation fuel.

10.2.4 Draw a baseline from just before the beginning of the non-aromatics peak to a point on the chromatogram where the baseline is stable and flat and all components have eluted. Drop vertical lines from valley to baseline at the appropriate points (see Fig. 1), and measure peak areas for MAHs and DAHs.

NOTE 20 - If the chromatographic data have been processed automatically, visually check to see that the integration parameters have correctly identified and integrated the peaks.

11. Calculation

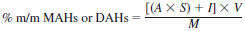

11.1 Percent m/m Aromatic Hydrocarbon Type Contents - Calculate the percent m/m contents for MAHs and DAHs using the following equation:

where:

A = MAH or DAH peak area for the sample,

S = slope of MAH or DAH calibration plot (% m/v versus peak area),

I = intercept of MAH or DAH % m/v calibration plot,

M = mass (g) of test portion taken (see 10.2.1), and

V = total volume (mL) of test portion solution (see 10.2.1).

NOTE 21 - This calculation may be performed directly by the data system.

NOTE 22 - To determine % (V/V) aromatic hydrocarbon types, use slope and intercept values from the % (V/V) calibration plots (see Note 18) and sample volume (see Note 19) in place of S, I, and M.

11.2 Total Aromatic Hydrocarbon Content - Calculate the total aromatic hydrocarbon content of the sample (percent m/m) as the sum of the individual hydrocarbon types (that is, MAHs + DAHs).