ASTM D6379 Standard Test Method for Determination of Aromatic Hydrocarbon Types in Aviation Fuels and Petroleum Distillates - High Performance Liquid Chromatography Method with Refractive Index Detection

9. Apparatus Preparation

9.1 Set up the chromatograph, injection system, column and column oven, refractive index detector, and computing integrator in accordance with the appropriate equipment manuals. The HPLC column shall be installed in the column oven.

NOTE 8 - The column oven is optional if alternative arrangements are made to maintain a constant temperature environment, for example, a temperature-controlled laboratory (see 6.5).

9.2 Adjust the flow rate of the mobile phase to a constant 1.0 more or less 0.2 mL/min and ensure that the reference cell of the refractive index detector is full of mobile phase (see 6.6.1). Allow the temperature of the column oven (and refractive index detector if equipped with temperature control) to stabilize.

9.2.1 To minimize drift, it is essential to make sure that the reference cell is full of solvent. The best way to accomplish this is either to (1) flush the mobile phase through the reference cell (then isolate the reference cell to prevent evaporation of the solvent) immediately prior to analysis, or (2) continuously make up for solvent evaporation by supplying a steady flow through the reference cell. The makeup flow is optimized so that reference and analytical cell mismatch due to drying-out, temperature, or pressure gradients are minimized. Typically this can be accomplished with a makeup flow set at one tenth of the analytical flow.

NOTE 9 - The flow rate may be adjusted (typically within the range from 0.8 to 1.2 mL/min) to an optimum value to meet the resolution requirements specified in 9.4.3.

9.3 Prepare a system resolution standard (SRS) by weighing cyclohexane (1.0 more or less 0.1 g), o-xylene (0.5 more or less 0.05 g), and 1-methylnaphthalene (0.05 more or less 0.005 g) into a 100 mL volumetric flask and making up to the mark with heptane.

NOTE 10 - The SRS may be kept for up to one year if stored in a tightly stoppered bottle in a dark place between 5 and 25°C.

9.4 When operating conditions are steady, as indicated by a stable horizontal baseline, inject 10 µL of the SRS (see 9.3) and record the chromatogram using the data system.

NOTE 11 - Baseline drift over the period of the HPLC analysis run should be less than 0.5 % of the peak height for cyclohexane. A baseline drift greater than this indicates problems with the temperature control of the column/refractive index or polar material eluting from the column, or both. A period of up to 1 h may be required before the liquid chromatograph reaches steady state conditions.

9.4.1 Ensure that baseline separation is obtained between all three components of the SRS.

9.4.2 Ensure that the data system can accurately measure the peak area of 1-methylnaphthalene.

NOTE 12 - The S/N (signal to noise) ratio for 1-methylnaphthalene should be 3:1 or greater.

9.4.3 Ensure that the resolution between cyclohexane and o-xylene is not less than five.

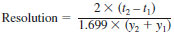

9.4.3.1 Column Resolution - Calculate the resolution between cyclohexane and o-xylene as follows:

where:

t1 = retention time of cyclohexane peak in seconds,

t2 = retention time of o-xylene peak in seconds,

y1 = half-height peak width of cyclohexane in seconds, and

y2 = half-height peak width of o-xylene in seconds.

If the resolution is less than five, check to see that all system components are functioning correctly and that the chromatographic dead volume has been minimized. Adjust the flow rate to see if this improves the resolution, and make sure that the mobile phase is of sufficiently high quality. Finally, regenerate or replace the column.

9.5 Repeat 9.4, and ensure that the repeatabilities for peak area measurements of o-xylene and 1-methylnaphthalene are within the precision of this test method.

NOTE 13 - If peak area repeatabilities are poor, check to see that the injection system is working optimally and that the baseline is stable (minimal drift) and noise-free.