ASTM D6300 Standard Practice for Determination of Precision and Bias Data for Use in Test Methods for Petroleum Products and Lubricants

1. Scope

1.1 This practice covers the necessary preparations and planning for the conduct of interlaboratory programs for the development of estimates of precision (determinability, repeatability, and reproducibility) and of bias (absolute and relative), and further presents the standard phraseology for incorporating such information into standard test methods.

1.2 This practice is generally limited to homogeneous products with which serious sampling problems do not normally arise.

1.3 This practice may not be suitable for solid or semisolid products such as petroleum coke, industrial pitches, paraffin waxes, greases, or solid lubricants when the heterogeneous properties of the substances create sampling problems. In such instances, use Practice E 691 or consult a trained statistician.

2. Referenced Documents

2.1 ASTM Standards:

D 123 Terminology Relating to Textiles

D 3244 Practice for Utilization of Test Data to Determine Conformance with Specifications

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E 456 Terminology Relating to Quality and Statistics

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

2.2 ISO Standards:

ISO 4259 Petroleum Products-Determination and Application of Precision Data in Relation to Methods of Test

3. Terminology

3.1 Definitions:

3.1.1 analysis of variance (ANOVA), n - a procedure for dividing the total variation of a set of data into two or more parts, one of which estimates the error due to selecting and testing specimens and the other part(s) possible sources of added variation.

3.1.2 bias, n - the difference between the population mean of the test results and an accepted reference value.

3.1.3 bias, relative, n - the difference between the population mean of the test results and an accepted reference value, which is the agreed upon value obtained using an accepted reference method for measuring the same property.

3.1.4 degrees of freedom, n - the divisor used in the calculation of variance.

3.1.4.1 Discussion - This definition applies strictly only in the simplest cases. Complete definitions are beyond the scope of this practice.

3.1.5 determinability, n - a quantitative measure of the variability associated with the same operator in a given laboratory obtaining successive determined values using the same apparatus for a series of operations leading to a single result; it is defined as that difference between two such single determined values as would be exceeded in the long run in only one case in 20 in the normal and correct operation of the test method.

3.1.5.1 Discussion - This definition implies that two determined values, obtained under determinability conditions, which differ by more than the determinability value should be considered suspect. If an operator obtains more than two determinations, then it would usually be satisfactory to check the most discordant determination against the mean of the remainder, using determinability as the critical difference (2).

3.1.6 mean square, n - in analysis of variance, a contraction of the expression "mean of the squared deviations from the appropriate average(s)" where the divisor of each sum of squares is the appropriate degrees of freedom.

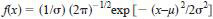

3.1.7 normal distribution, n - the distribution that has the probability function:

where:

x = a random variate,

µ = the mean distribution, and

s = the standard deviation of the distribution. (Syn. Gaussian distribution, law of error)

3.1.8 outlier, n - a result far enough in magnitude from other results to be considered not a part of the set.

3.1.9 precision, n - the degree of agreement between two or more results on the same property of identical test material. In this practice, precision statements are framed in terms of repeatability and reproducibility of the test method.

3.1.9.1 Discussion - The testing conditions represented by repeatability and reproducibility should reflect the normal extremes of variability under which the test is commonly used. Repeatability conditions are those showing the least variation; reproducibility, the usual maximum degree of variability. Refer to the definitions of each of these terms for greater detail.

3.1.10 random error, n - the chance variation encountered in all test work despite the closest control of variables.

3.1.11 repeatability, n - the quantitative expression of the random error associated with a single operator in a given laboratory obtaining repetitive results with the same apparatus under constant operating conditions on identical test material. It is defined as the difference between two such results at the 95 % confidence level.

3.1.11.1 Discussion - Interpret as the value equal to or below which the absolute difference between two single test results obtained in the above conditions may expect to lie with a probability of 95 %.

3.1.11.2 Discussion - The difference is related to the repeatability standard deviation but it is not the standard deviation or its estimate.

3.1.12 reproducibility, n - a quantitative expression of the random error associated with different operators using different apparatus, etc., each obtaining a single result on an identical test sample when applying the same method. It is defined as the 95 % confidence limit for the difference between two such single and independent results.

3.1.12.1 Discussion - Interpret as the value equal to or below which the absolute difference between two single test results on identical material obtained by operators in different laboratories, using the standardized test, may be expected to lie with a probability of 95 %.

3.1.12.2 Discussion - The difference is related to the reproducibility standard deviation but is not the standard deviation or its estimate.

3.1.12.3 Discussion - In those cases where the normal use of the test method does not involve sending a sample to a testing laboratory, either because it is an in-line test method or because of serious sample instabilities or similar reasons, the precision test for obtaining reproducibility may allow for the use of apparatus from the participating laboratories at a common site (several common sites, if feasible). The statistical analysis is not affected thereby. However, the interpretation of the reproducibility value will be affected, and therefore, the precision statement shall, in this case, state the conditions to which the reproducibility value applies.

3.1.13 standard deviation, n - the most usual measure of the dispersion of observed values or results expressed as the positive square root of the variance.

3.1.14 sum of squares, n - in analysis of variance, a contraction of the expression "sum of the squared deviations from the appropriate average(s)" where the average(s) of interest may be the average(s) of specific subset(s) of data or of the entire set of data.

3.1.15 variance, n - a measure of the dispersion of a series of accepted results about their average. It is equal to the sum of the squares of the deviation of each result from the average, divided by the number of degrees of freedom.

3.1.16 variance, between-laboratory, n - that component of the overall variance due to the difference in the mean values obtained by different laboratories.

3.1.16.1 Discussion - When results obtained by more than one laboratory are compared, the scatter is usually wider than when the same number of tests are carried out by a single laboratory, and there is some variation between means obtained by different laboratories. Differences in operator technique, instrumentation, environment, and sample "as received" are among the factors that can affect the between laboratory variance. There is a corresponding definition for between-operator variance.

3.1.16.2 Discussion - The term "between-laboratory" is often shortened to "laboratory" when used to qualify representative parameters of the dispersion of the population of results, for example as "laboratory variance".

3.2 Definitions of Terms Specific to This Standard:

3.2.1 determination, n - the process of carrying out a series of operations specified in the test method whereby a single value is obtained.

3.2.2 operator, n - a person who carries out a particular test.

3.2.3 probability density function, n - function which yields the probability that the random variable takes on any one of its admissible values; here, we are interested only in the normal probability.

3.2.4 result, n - the final value obtained by following the complete set of instructions in the test method.

3.2.4.1 Discussion - It may be obtained from a single determination or from several determinations, depending on the instructions in the method. When rounding off results, the procedures described in Practice E 29 shall be used.