ASTM D6296 Standard Test Method for Total Olefins in Spark-ignition Engine Fuels by Multi-dimensional Gas Chromatography

11. Calibration

11.1 Blank Compensation - Analyze a sample of pure isooctane in duplicate and discard the first analysis. The blank signal from the second analysis is recorded and stored by the software to be subtracted from the signal obtained for the olefins during the calibration or sample analysis. The blank must be analyzed immediately before, and every time, a calibration is run.

11.2 Calibration - Confirms that the chromatographic separation is performed as required, determines the retention times of the olefins by carbon number, and determines the response factor on the FID for the olefins.

11.2.1 Analyze Calibration Standard 1 for all samples except those that contain ETBE as described in 10.3. When ETBE is present, analyze Calibration Standard 2.

11.2.1.1 A typical chromatogram of Calibration Standard 1 is shown in Fig. 2. Visually inspect the chromatogram obtained to verify that symmetrical peaks are obtained for all olefins, that undecane completely elutes before 10 min, and that no ether peak elutes immediately before pentene. From the recorded areas of the olefin peaks and the known concentrations in the blend, verify that the calculated concentration for the individual olefin peaks is satisfactory (see Note 12). If any of the above conditions is not met, reoptimize the system to confirm that column/trap temperatures and cut times are correct.

NOTE 15 - The recorded areas of the olefins are blank subtracted as described in 11.1.

11.2.2 Response Factor, mass % - Calculate a response factor for the total olefins in mass %/area, using Eq 3.

NOTE 16 - Only the integrated areas of the C6 through C9 olefin peaks are used for calculation of the response factor.

where:

Rfmass = response factor for total olefins, mass %/area,

Gmass = concentration of C6 through C9 olefins in the calibration standard (Standard 1 or 2), mass %, and

A = integrated area of the C6 through C9 olefin peaks in the calibration blend.

11.2.3 Response Factor, Volume % - To obtain a volume % result, the mass-based response of the olefins must be converted to a volume-based response. To accomplish this conversion, the density of the olefin fraction must be calculated. The computer software is able to perform this calculation using the retention times of the C5 to C10 olefins as recorded in the calibration run and the known densities of the individual blended olefins, which are similar to olefinic components in samples. The density for area slices at specific retention times (between carbon numbers) is calculated by using a linear interpolation of adjacent densities. The integrated area of each carbon number slice from the sample chromatogram is divided by the appropriate density. The corrected areas are then summed to produce a total area that is corrected for olefin density (see Note 15).

11.2.3.1 Calculate a response factor for the total olefins in volume %/area using Eq 4.

where:

Rfvol = response factor for total olefins, volume %/area,

Gvol = concentration of the C6 through C9 olefins in the calibration standard (Standard 1 or 2), volume %, and

Acor = integrated area of the C6 through C9 olefin peaks in the calibration blend corrected for density (see 11.2.3).

12. Calculation

12.1 Examine the report carefully to ensure that peak areas for the olefins have been properly integrated.

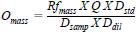

12.2 Total Olefins, mass % - To obtain a mass-percent result, the injected volume of sample must be converted to the injected mass of the sample. The density, which must be determined (see Eq 2), on each analyzed sample is used for this conversion. The calculation of total olefins can be performed by the software when the calibration standard density, sample density, and dilution have been entered prior to sample analysis, or the total olefins, mass %, can be calculated using Eq 5.

where:

Omass = total olefins, mass %,

Rfmass = response factor, previously defined, Eq 3,

Dstd = density of the calibration standard, kg/L,

Dsamp = density of the sample, kg/L, previously calculated, Eq 2,

Ddil = dilution factor for the sample, previously calculated, Eq 1, and

Q = integrated area of the total olefins from the sample chromatogram.

12.3 Total Olefins, Volume % - The calculation of total olefins can be performed by the software when the dilution factor has been entered prior to sample analysis, or the total olefins, volume %, can be calculated using Eq 6.

where:

OLV = total olefins, liquid-volume %,

Rfvol = response factor, previously defined, Eq 4,

Qcor = integrated area of the total olefins from the sample chromatogram corrected for density (see 11.2.3), and

Ddil = dilution factor for the sample, previously calculated, Eq 1.