ASTM D6201 Standard Test Method for Dynamometer Evaluation of Unleaded Spark-Ignition Engine Fuel for Intake Valve Deposit Formation

1. Scope

1.1 This test method coves an engine dynamometer test procedure for evaluation of intake valve deposit formation of unleaded spark-ignition engine fuels. This test uses a Ford Ranger 2.3 L four-cylinder engine. The following details the procedure, hardware, and operations used for this test.

1.2 The ASTM Test Monitoring Center (TMC) is responsible for engine test stand certification as well as issuance of information letters after test method modifications are approved by Subcommittee D02.A and Committee D02. Users of this test method shall request copies of recent information letters from the TMC to ensure proper conduct of the test method.

1.3 The values stated in SI units are to be regarded as the standard. Approximate inch-pound units are shown in parenthesis for information.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine applicability of regulatory limitations prior to use. Specific precautionary statements are given throughout this test method.

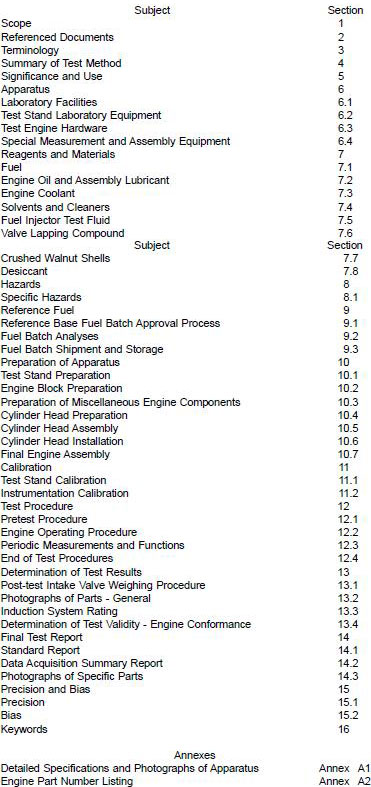

1.5 This test method is arranged as follows:

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvents)

D287 Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)

D381 Test Method for Existent Gum in Fuels by Jet Evaporation

D525 Test Method for Oxidation Stability of Gasoline (Induction Period Method)

D873 Test Method for Oxidation Stability of Aviation Fuels (Potential Residue Method)

D1266 Test Method for Sulfur in Petroleum Products (Lamp Method)

D1298 Practice for Density, Relative Density (Specific Gravity), or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D1744 Test Method for Determination of Water in Liquid Petroleum Products by Karl Fischer Reagent

D2427 Test Method for Determination of C2 Through C5 Hydrocarbons in Gasolines by Gas Chromatography

D2622 Test Method for Sulfur in Petroleum Products by X-ray Spectrometry

D3237 Test Method for Lead in Gasoline by Atomic Absorption Spectrometry

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4294 Test Method for Sulfur in Petroleum Products by Energy-Dispersive X-ray Fluorescence Spectroscopy

D4814 Specification for Automotive Spark-Ignition Engine Fuel

D4953 Test Method for Vapor Pressure of Gasoline and Gasoline-Oxygenate Blends (Dry Method)

D5059 Test Method for Lead in Gasoline by X-ray Spectroscopy

D5190 Test Method for Vapor Pressure of Petroleum Products (Automatic Method)

D5191 Test Method for Vapor Pressure of Petroleum Products (Mini Method)

D5302 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Deposit Formation and Wear in a Spark-Ignition Internal Combustion Engine Fueled with Gasoline and Operated under Low-Temperature, Light-Duty Conditions

D 5482 Test Method for Vapor Pressure of Petroleum Products (Mini Method - Atmospheric)

E 203 Test Method for Water Using Volumetric Karl Fischer Titration

E 1064 Test Method for Water in Organic Liquids by Coulometric Karl Fischer Titration

2.2 ANSI Standard:

MC96.1 Temperature Measurement-Thermocouples

2.3 Coordinating Research Council (CRC):

CRC Manual 16, Carburetor and Induction System Rating Manual

2.4 SAE Standard:

J254 Instrumentation and Techniques for Exhaust Gas Emissions Measurement

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 base fuel, n - unleaded automotive spark-ignition engine fuel that does not contain a deposit control additive, but may contain antioxidants, corrosion inhibitors, metal deactivators, dyes, or oxygenates, or a combination thereof.

3.1.2 blowby, n - the combustion products and unburned air/fuel mixture that enter the crankcase.

3.1.3 deposit control additive, n - material added to the base fuel to prevent or remove deposits in the entire engine intake system.

3.1.3.1 Discussion - For the purpose of this test method, the performance evaluation of a deposit control additive is limited to the tulip area of intake valves.

3.1.4 exhaust emissions, n - combustion products from the test fuel including unburned hydrocarbons (HC), carbon monoxide (CO), carbon dioxide (CO2), unreacted oxygen (O2), and oxides of nitrogen (NOx).

3.1.5 intake system, n - components of the engine whose function it is to prepare and deliver an air/fuel mixture to the combustion chamber and includes the throttle, intake manifold, exhaust gas recirculation (EGR) and positive crankcase ventilation (PCV) ports, cylinder head runners and ports, intake valves, and fuel injectors.

3.1.6 intake valve deposit, n - material accumulated on the tulip area of the intake valve, generally composed of carbon, other fuel, lubricant, and additive decomposition products, and atmospheric contaminants.

3.1.7 test fuel, n - base fuel with or without the addition of a deposit control additive.