9. Procedure

9.1 Preheat the oven to test temperature. Unless otherwise specified, the test shall be conducted at standard conditions of 100 +/- 0.5°C for 30 +/- 0.25 h.

9.2 Weigh the beaker to within 0.01 g, Wi.

9.3 Tare the assembled apparatus consisting of the sieve, cover, and beaker as shown in Fig. 1 to the nearest 0.01 g.

9.4 With a suitable spatula, fill the cone sieve with sufficient grease to approximate the level shown in Fig.1, being careful to avoid inclusion of air. Exercise care not to force grease through the screen. Smooth and shape the top of the grease into a slightly convex surface to prevent trapping free oil.

9.5 Assemble the entire apparatus as shown in Fig.1, and weigh to the nearest 0.01 g. Calculate the mass of the grease by difference, G.

9.6 Place the assembled apparatus in the oven for the specified time and temperature.

9.7 Remove the apparatus from the oven and cool to room temperature. Remove the cone from the beaker, tapping it gently against the inside of the beaker to take off any oil adhering to its tip. Weigh the beaker containing the collected oil to the nearest 0.01 g, Wf.

9.8 Soon after completion of the test, clean the apparatus (Section 8) in preparation for subsequent testing.

10. Calculation

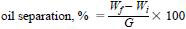

10.1 Calculate the oil separation as the percentage separated from the original sample as follows:

where:

Wi = mass of the beaker before heating,

Wf = mass of the beaker after heating, and

G = mass of the grease tested.