12. Procedure

12.1 Bracketing by Handwheel Procedure - See Appendix X2 for the details of engine operation and the adjustment of each of the individual operating variables.

12.1.1 Check that all engine operating conditions are in compliance and equilibrated with the engine running on a typical diesel fuel oil. (Warning - In addition to other precautions, always position the ignition delay meter (Mark II and earlier models) to CALIBRATE before proceeding with fuel switching so that violent meter needle full-scale pegging does not occur. Calibration adjustment should be checked before each rating but never changed during a rating.)

12.1.2 Introduce the sample to an empty fuel tank, rinse the fuel buret, purge any air from the fuel line to the pump and position the fuel-selector valve to operate the engine on this fuel. (Warning - Sample and Fuel - Combustible. Vapor Harmful. See Annex A1.)

12.1.3 Fuel Flow Rate - Check the fuel flow rate and adjust the flow-rate-micrometer of the fuel pump to obtain 13 mL per min consumption. The final flow rate measurement shall be made over a full 60 more or less 1 s period. Note the flow-rate-micrometer reading for reference.

12.1.4 Fuel Injection Timing - After establishing the fuel flow rate, adjust the injection-timing-micrometer of the fuel pump assembly to obtain a 13.0 more or less 0.2° injection advance reading. Note the injection-timing-micrometer reading for reference.

12.1.5 Ignition Delay - Adjust the handwheel to change the compression ratio and obtain a 13.0 more or less 0.2° ignition delay reading. Make the final handwheel adjustment in the clockwise direction (viewed from front of engine) to eliminate backlash in the handwheel mechanism and a potential error.

12.1.6 Equilibration - It is important to achieve stable injection advance and ignition delay readings.

12.1.6.1 Stable readings should typically occur within 5 to 10 min.

12.1.6.2 The time used for the sample and each of the reference fuels should be consistent and shall not be less than 3 min.

12.1.7 Handwheel Reading - Observe and record the handwheel reading as the representative indication of the combustion characteristic for this fuel sample.

12.1.8 Reference Fuel No. 1 - Select a secondary reference fuel (T Fuel and U Fuel) blend close to the estimated cetane number of the sample.

NOTE 1 - The handwheel reading vs cetane number relationship based on this procedure is engine and overhaul dependent but it can be established for each engine as testing experience is gained after each overhaul. A plot or table of handwheel readings provides a simple guide to selection of the reference fuel.

12.1.8.1 Prepare a fresh 400 or 500 mL batch of the selected reference blend.

12.1.8.2 Introduce Reference Fuel No. 1 to one of the unused fuel tanks taking care to flush the fuel lines in the same manner as noted for the sample.

12.1.8.3 Perform the same adjustment and measurement steps used for the sample and record the resulting handwheel reading.

12.1.9 Reference Fuel No. 2 - Select another secondary reference fuel blend which can be expected to result in a handwheel reading that causes the two reference fuel handwheel readings to bracket that for the sample. The difference between the two reference fuel blends shall not exceed 5.5 cetane numbers. Typically, blends differing by 5 volume percent T Fuel will span about 2.7 cetane numbers and those differing by 10 volume percent T Fuel will span about 5.3 cetane numbers.

12.1.9.1 Prepare a fresh 400 or 500 mL batch of the selected reference fuel blend.

12.1.9.2 Introduce Reference Fuel No. 2 to the third fuel tank taking care to flush the fuel lines in the same manner as noted for the sample.

12.1.9.3 Perform the same adjustment and measurement steps used for the sample and first reference fuel and record the resulting handwheel reading.

NOTE 2 - Typically, the fuel-flow-rate should be the same for both reference fuels because they are sufficiently similar in composition.

12.1.9.4 If the handwheel reading for the sample is bracketed by those of the reference fuel blends, continue the test; otherwise try an additional reference fuel blend(s) until this requirement is satisfied.

12.1.10 Repeat Readings - After operation on a satisfactory second reference fuel blend, perform the necessary steps to rerun Reference Fuel No. 1, then the sample and finally Reference Fuel No. 2. For each fuel, be certain to check all parameters carefully and allow operation to reach equilibrium before recording the handwheel readings. The fuel switching shall be as illustrated in Fig. 3 Sample and Reference Fuel Reading Sequence A.

12.1.10.1 If a sample is tested immediately following one for which the Reference Fuel No. 2 will be applicable, that reference fuel handwheel reading can be utilized for the new sample. The fuel switching shall thus be as illustrated in Fig. 3, Sample and Reference Fuel Reading Sequence B.

13. Calculation of Cetane Number

13.1 Calculate the average handwheel readings for the sample and each of the reference fuel blends.

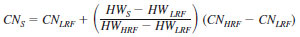

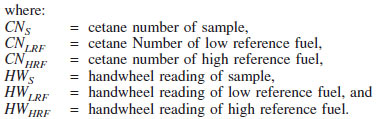

13.2 Calculate the cetane number by interpolation of these average handwheel readings proportioned to the cetane numbers of the bracketing reference fuel blends in accordance with Eq 4. See Fig. 4.

13.2.1 For the Handwheel Bracketing Procedure:

13.2.2 Do not interpolate using reference fuel blend volume percent of T Fuel values and convert that equivalent percent to cetane number.

13.3 Round the calculated cetane number to the nearest tenth. Any cetane number ending in exactly 5 in the second decimal place shall be rounded to the nearest even tenth number; for example, round 35.55 and 35.65 to 35.6 cetane number.