7. Interpretation of Results

7.1 The designation determined for a hydraulic fluid as described in 6.4 may be used in combination with a manufacturer's viscosity recommendations for specific equipment to estimate an acceptable temperature range over which that fluid may be used in that equipment.

7.2 The low temperature grade determined in 6.1, Lyy, defines the lowest recommended fluid temperature at which the fluid may be used in equipment with a start-up, under load limit of 750 mPa•s, max.

7.2.1 The low temperature limit is determined by comparing the Lyy designation with the corresponding temperature in Table 1.

7.2.2 Example 1a - For an oil with the designation:

ISO VG 46

L32-40 ,

the low temperature grade is defined by L32. Reference to Table 1 indicates that this oil has a viscosity of 750 mPa•s at a temperature between -8 and -14°C. Hence, in equipment which has a low temperature start-up viscosity limit of 750 mPa•s, the oil in this example may be used down to at least -8°C.

7.2.3 Example 2a - For an oil with the designation:

ISO VG 68

L46-57

the low temperature grade is defined by L46. Reference to Table 1 indicates that this oil has a viscosity of 750 mPa•s at a temperature between -2 and -7°C. Hence, in equipment which has a low temperature start-up viscosity limit of 750 mPa•s, the oil in this example may be used down to at least -2°C.

7.2.4 This practice is not quantitative when a manufacturer specifies lower or higher start-up viscosity limits. However, the process described in 6.1 can be used to determine low temperature limitations corresponding to any start-up viscosity.

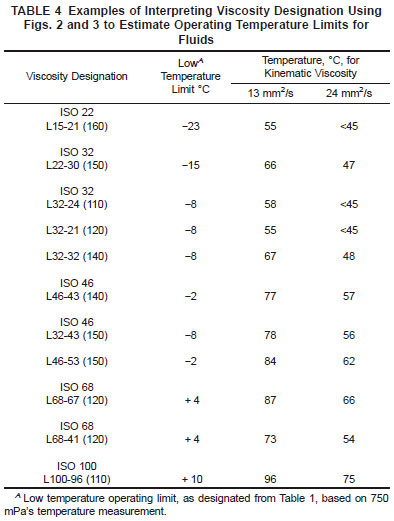

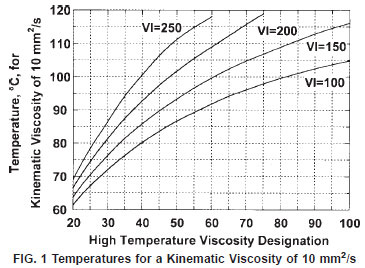

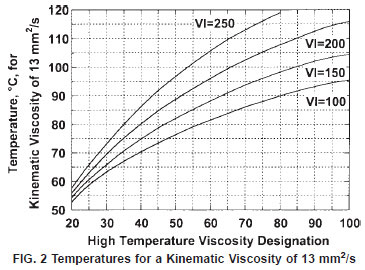

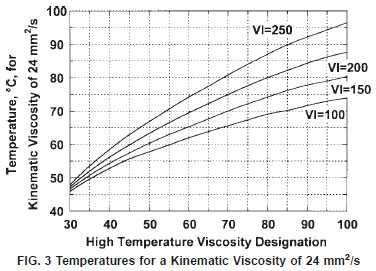

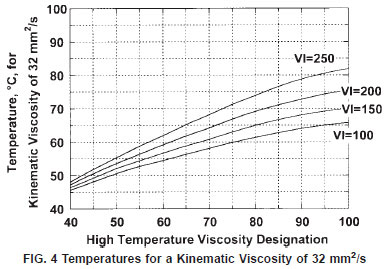

7.3 The high temperature designation determined in 6.2 and the viscosity index determined in 6.3, zz (VI), can be used in combination with the data in Figs. 1-4 to estimate high temperature operating limits (Fig. 1 and Fig. 2) and optimum operating temperatures (Fig. 3 and Fig. 4) for the fluid.

7.3.1 Fig. 1 and Fig. 2 apply directly to equipment which has minimum operating kinematic viscosity limits of 10 and 13 mm2/s, respectively.

7.3.1.1 Find the value zz on the horizontal axis labeled High Temperature Viscosity Designation.

7.3.1.2 Read vertically from the point defined by 7.3.1.1 to the curve corresponding to the viscosity index, VI, interpolating, if necessary.

7.3.1.3 Read horizontally from the point defined by 7.3.1.2 to the vertical axis labeled Temperature, °C, for a Kinematic Viscosity of 10 (or 13) mm2/s. This is the upper temperature limit for fluid operation.

7.3.1.4 Example 1b - For the oil in Example 1a in 7.2.2, the high temperature designation and VI are 40 and 150, respectively. Assume that the equipment of interest has a recommended kinematic viscosity minimum of 13 mm2/s; hence, Fig. 2 should be used. As described in 7.3.1.1, find the value 40 on the horizontal axis labeled High Temperature Viscosity Designation. As described in 7.3.1.2, read vertically from 40 until intersecting the curve labeled VI = 150. Finally, as described in 7.3.1.3, read horizontally to the vertical axis labeled Temperature, °C, for a Kinematic Viscosity of 13 mm2/s. The value corresponding to a high temperature viscosity designation of 40 and a viscosity index of 150 is 75°C. Hence, in equipment which has a recommended kinematic viscosity minimum of 13 mm2/s, fluid temperature for the oil in this example should not exceed 75°C.

7.3.1.5 Example 2b - For the oil in Example 2a in 7.2.3, the high temperature designation and VI are 57 and 170, respectively. Assume that the equipment of interest has a recommended kinematic viscosity minimum of 10 mm2/s; hence, Fig. 1 should be used. Find the value 57 on the horizontal axis labeled High Temperature Viscosity Designation. Read vertically from 57 until intersecting the curves labeled VI = 150 and VI = 200. Interpolate between the curves to a value of VI = 170 and read horizontally to the vertical axis labeled Temperature, °C, for a Kinematic Viscosity of 10 mm2/s. The value corresponding to a high temperature viscosity designation of 57 and a viscosity index of 170 is 102°C. Hence, in equipment which has a recommended kinematic viscosity minimum of 10 mm2/s, fluid temperature for the oil in this example should not exceed 102°C.

7.3.1.6 Approximate maximum fluid operating temperature can also be estimated for other minimum operating viscosities in the range of 10 to 13 mm2/s by interpolation between Fig. 1 and Fig. 2.

7.3.2 Fig. 3 and Fig. 4 apply directly to equipment which has optimum operating viscosities of either 24 or 32 mm2/s, respectively.

7.3.2.1 Find the value zz on the horizontal axis labeled High Temperature Viscosity Designation.

7.3.2.2 Read vertically from the point defined by 7.3.2.1 to the curve corresponding to the viscosity index, VI, interpolating, if necessary.

7.3.2.3 Read horizontally from the point defined by 7.3.2.2 to the vertical axis labeled Temperature, °C, for a Kinematic Viscosity of 24 (or 32) mm2/s. This is the optimum temperature for fluid operation.

7.3.2.4 Example 1c - For the oil in Example 1a in 7.2.2, the high temperature designation and VI are 40 and 150, respectively. Assume that the equipment of interest has a recommended optimum operating kinematic viscosity of 24 mm2/s; hence, Fig. 3 should be used. As described in 7.3.2.1, find the value 40 on the horizontal axis labeled High Temperature Viscosity Designation. As described in 7.3.2.2, read vertically from 40 until intersecting the curve labeled VI = 150. Finally, as described in 7.3.2.3, read horizontally to the vertical axis labeled Temperature, ° C, for a Kinematic Viscosity of 24 mm2/s. The value corresponding to a high temperature viscosity designation of 40 and a viscosity index of 150 is 54 to 55°C. Hence, in equipment which has a recommended optimum operating kinematic viscosity of 24 mm2/s, fluid temperature for the oil in this example should be maintained at about 54 to 55°C.

7.3.2.5 Example 2c - For the oil in Example 2a in 7.2.3, the high temperature designation and VI are 57 and 170, respectively. Assume that the equipment of interest has a recommended optimum operating kinematic viscosity of 32 mm2/s; hence, Fig. 4 should be used. Find the value 57 on the horizontal axis labeled High Temperature Viscosity Designation. Read vertically from 57 until intersecting the curves labeled VI = 150 and VI = 200. Interpolate between the curves to a value of VI = 170 and read horizontally to the vertical axis labeled Temperature, °C, for a Kinematic Viscosity of 32 mm2/s. The value corresponding to a high temperature viscosity designation of 57 and a viscosity index of 170 is 56°C. Hence, in equipment which has a recommended optimum operating kinematic viscosity of 32 mm2/s, fluid temperature for the oil in this example should be maintained at about 56°C.

7.3.2.6 Approximate optimum fluid operating temperature can also be estimated for other optimum operating viscosities in the range of 24 to 32 mm2/s by interpolation between Fig. 3 and Fig. 4.

7.4 Examples of the application of Fig. 2 and Fig. 3 to the oils described in Table 3 (6.4.2) are shown in Table 4.