6. Procedure

6.1 The low temperature viscosity grade of a fluid is based on the viscosity of new oil measured using a Brookfield viscometer, Test Method D2983.

6.1.1 The viscosity shall be interpolated from measurements at three temperatures spanning the temperature at which the viscosity is 750 mPa•s. A smooth graph of these data (log viscosity versus temperature) determines the temperature at which the oil has a viscosity of 750 mPa•s.

6.1.2 The lower viscosity limit for Test Method D2983 is currently stated to be 1000 mPa•s. This equipment limitation is shown in Table 1 of that method. Newer equipment is available which permits measurement of lower viscosities and Test Method D2983 is currently being revised with a lower viscosity limit of 500 mPa•s.

6.1.3 The temperature determined in 6.1.1 shall be rounded to a whole number in accordance with Practice E 29.

6.1.4 The low temperature viscosity grade is determined by matching the temperature determined in 6.1.3 with the requirements shown in Table 1.

6.2 The high temperature viscosity designation of a fluid is the 40°C kinematic viscosity (Test Method D445) of a fluid which has been sheared using Test Method D5621.

6.2.1 The kinematic viscosity determined in 6.2 shall be rounded to a whole number in accordance with Practice E 29.

6.2.2 For a fluid known to contain no polymeric components which will shear degrade, the high temperature viscosity designation is the 40°C kinematic viscosity (Test Method D445) of the new fluid, rounded per 6.2.1.

6.2.3 If the 40°C kinematic viscosity from 6.2.1 fails to meet the same designation consistently (for example, it varies because of spread in base stock or component specifications, or variability in kinematic viscosity or shear stability measurements), the lower designation must be used to ensure conformance with 6.5 below.

6.3 The viscosity index designation of the fluid is based on the viscosity index as determined using Practice D2270 on fluid which has been sheared using Test Method D5621.

6.3.1 The viscosity index determined in 6.3 shall be rounded to the nearest ten units in accordance with Practice E 29. This value is the viscosity index designation.

6.3.2 For fluids which do not contain polymeric components, the viscosity index is determined on the new fluid using Practice D2270. The viscosity index designation for the fluid is established by rounding this viscosity index to the nearest ten units in accordance with Practice E 29.

NOTE 2 - The guidelines for rounding viscosity in 6.2.1 and 6.2.2 and viscosity index in 6.3.1 and 6.3.2 are specific to this practice and should not be confused with the larger number of significant figures that can be reported when Test Methods D445 and D2270 are used for other purposes.

6.3.3 If the viscosity index fails to meet the same designation consistently, that is, it varies between the lower values for one designation and the higher values for the next lower designation (for example, it varies because of spread in base stock or component specifications, or variability in kinematic viscosity or shear stability measurements), the lower designation must be used to ensure conformance with 6.5 below.

6.4 For the sake of uniformity of nomenclature in identifying the viscosity characteristics of hydraulic fluids, the following designation shall be used:

ISO VG xx

Lyy-zz (VI)

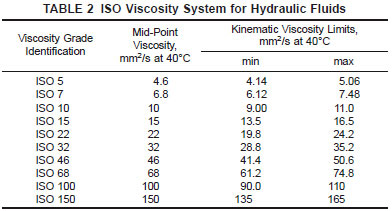

where xx is the new oil viscosity grade as determined by Classification D2422 (Table 2); Lyy is the low temperature viscosity grade as determined in 6.1; zz is the high temperature sheared viscosity designation as determined in 6.2; and VI is the viscosity index designation as determined in 6.3.

6.4.1 If the new oil viscosity does not meet a grade described by Classification D2422, the ISO VG xx portion of the designation does not apply. In such cases, the Lyy-zz (VI) designation may still be used, and the use of any other descriptors for the new oil is at the discretion of the fluid marketer.

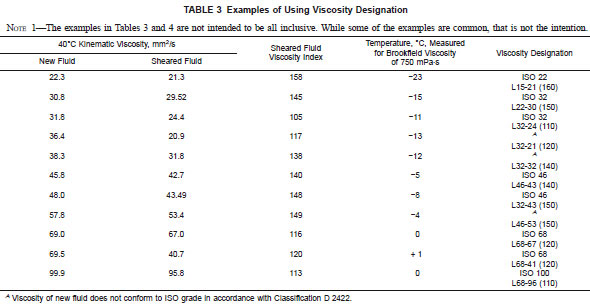

6.4.2 Examples of use of this practice are shown in Table 3.

6.5 An oil blender may use any manufacturing control that seems appropriate to his operation. However, it is the responsibility of the blender to ensure that all production fully meets the requirements for the viscosity designation on the container.