ASTM D6069 Standard Test Method for Trace Nitrogen in Aromatic Hydrocarbons by Oxidative Combustion and Reduced Pressure Chemiluminescence Detection

13. Procedure

13.1 Sample sizes from 5 to 50 µL are acceptable. Although, at the concentration range from 0.2 to 2 µg N/mL, it is recommended that the same size sample be used for all standards and samples analyses.

NOTE 4 - When an organic sample is injected into the pyrolysis furnace a pressure wave is formed. The initial flash vaporization forms a positive pressure pulse, thus decreasing detector sensitivity. After pyrolysis of the organic material in the high-temperature furnace a reduced pressure pulse is formed, resulting in increased detector sensitivity. Thus, maintaining the same sample size for all injections (that is, samples and standards) will improve repeatability and reproducibility. As mentioned in 8.4, Solvent, using a solvent with a boiling point similar to that of the sample being analyzed is generally recommended.

13.1.1 Always flush the syringe several times with the material to be injected. To prevent contamination do not return the first couple of flushes back into the specimen bottle.

13.1.2 If the instrument is equipped with a pyrolysis tube for direct syringe injection, see 13.2. If the instrument is equipped with a boat inlet system, see 13.3.

13.2 Fill syringe to approximately 1.5 times the volume to be injected (that is, to inject 10 µL, fill a 25-µL syringe with 15 to 20 µL of sample or standard), taking care not to pull air bubbles into the syringe with the sample. With the syringe needle pointed up, push the plunger in to the desired volume, tap the last drop off the needle point, and pull the plunger back until air can be seen in the syringe barrel.

NOTE 5 - The inherent accuracy of this technique is dependent upon the ability of the analyst to repeatability inject the same volume for each injection. Air bubbles lodged between the syringe plunger and the specimen will result in variable specimen volumes. If bubbles persist, try cleaning the syringe with a different solvent or try inserting the needle into a septum and gently putting pressure on the syringe plunger (this may cause persistent bubbles to break free).

NOTE 6 - If the detector response continuously increases or decreases, this is indicative of contamination. If this occurs, continue injecting the specimen until the detector signal shows a typical variance.

13.2.1 Insert the syringe needle through the inlet septum as far as it will go (the syringe barrel should be touching the septum). Allow the residual sample in the needle to burn-off. When the instrument returns to a stable baseline, zero or clear the detector display and inject the specimen or standard at a constant rate of 0.5 to 1.0 µL/s.

13.2.2 If an autosampler is used the detector will be automatically zeroed prior to injection.

13.2.3 Repeat 13.2 analyzing each standard and sample in triplicate. Average the three results for each standard or sample and record the results.

13.3 With the boat inlet system, a specimen is injected into a cool boat and the boat carried into the pyrolysis furnace. Before analyzing standards or samples introduce the boat into the furnace to burn-off any possible contamination.

13.3.1 Fill the syringe as described in 13.2. Inject the standard or specimen into the cooled boat. Move the boat containing the specimen into the furnace at a controlled and repeatable rate.

NOTE 7 - The boat may be stopped at the furnace inlet to permit evaporation, if a controlled combustion is necessary. Although, if the boat is stopped, it must then be stopped at the same place and for the same length of time for all analyses (see Note 4, Note 5, and Note 6).

13.3.2 Repeat 13.3 analyzing each sample, or standard in triplicate. Average the three results for each sample and record the results.

14. Calculation

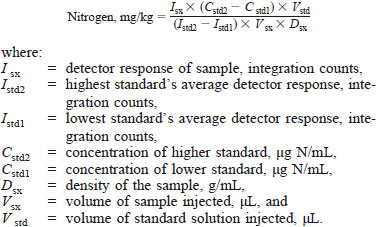

14.1 Calculate the concentration of nitrogen as follows: