ASTM D5986 Standard Test Method for Determination of Oxygenates, Benzene, Toluene, C8-C12 Aromatics and Total Aromatics in Finished Gasoline by Gas Chromatography/Fourier Transform Infrared Spectroscopy

9. Calibration Procedure

9.1 Preparation of Calibration Standards - Prepare multicomponent calibration standards using the compounds listed in Table 1 and Table 2 by mass according to Practice D4307. Prepare calibration solutions as described in 9.1-9.1.4 for each set. Adjust these concentrations, as necessary, to ensure that the concentrations of the components in the actual samples are bracketed by the calibration concentrations. Solid components are weighed directly into the flask or vial. The specified volumes of each calibration component are weighed into 100 mL volumetric flasks or 100 mL septum capped vials. Prepare a calibration standard as follows. Cap and record the tare weight of the 100 mL volumetric flask or vial to 0.1 mg. Remove the cap and carefully add components to the flask or vial starting with the least volatile component. Cap the flask and record the net mass (Wi) of the aromatic component added to 0.1 mg. Repeat the addition and weighing procedure for each component. Similarly add the internal standard and record its net mass (Ws) to 0.1 mg. Store the capped calibration standards in a refrigerator at 0 to 5°C (32 to 40°F) when not in use.

NOTE 2 - Mix all calibration solutions for at least 30 s on a Vortex mixer after preparation or equivalent. Highly precise sample robotic sample preparation systems are available commercially. These systems may be used provided that the results for the quality control reference material (Section 11) are met when prepared in this manner.

9.1.1 Ethers and Alcohols:

9.1.1.1 Three sets of at least six calibration levels each (eighteen total solutions) are prepared bracketing the 0 to 20 volume % range. Set 1: for MTBE, DIPE, ETBE, TAME; Set 2: MeOH, EtOH, 2-PrOH, t-BuOH; and Set 3: 1-PrOH, 2-BuOH, i-BuOH, 1-BuOH.

9.1.1.2 For each above Set: 1, 3, 5, 10, 15, and 20 mL aliquots of each component are pipetted into respective 100 mL volumetric flasks or vials while accurately recording the masses. For example, for Set 1, into flask one add 1.0 mL MTBE, 1.0 mL DIPE, 1.0 mL ETBE, 1.0 mL TAME; into flask two add 3.0 mL MTBE, 3.0 mL DIPE, 3.0 mL ETBE, 3.0 mL TAME; and so forth. Add the oxygenate in reverse order of their boiling points. The above procedure produces six calibration solutions for each set with the concentrations of each analyte at 1, 3, 5, 10, 15, and 20 volume %. 10.0 mL of DME (internal standard) is then added at constant volumes to each flask or vial while recording its mass. The flasks or vials are then filled to 100 mL total volume with toluene. It is not necessary to weigh the amount of solvent added since the calculations are based on the absolute masses of the calibration components and the internal standard components.

9.1.1.3 For best accuracy at concentrations below 1 %, prepare calibration standard sets to bracket the expected concentration. Some of the alcohols are present at low concentrations in gasoline blends. In this case, for example, if the expected analyte concentration is 0.5 volume %, prepare calibration solutions by mass in the range of 0.1 to 1.0 volume %. Furthermore, if the components in Set 3 are all at these low concentrations then for calibration they can be added to Set 2, thus reducing the calibration solutions to Sets 1 and 2.

9.1.2 Benzene, Toluene, Ethylbenzene, Xylenes (BTEX) (Table 3/Set A):

9.1.2.1 To each of six 100 mL volumetric flasks or vials, add 10.0 mL of DME and record the mass.

9.1.2.2 For ethylbenzene, m, p, and o-xylenes (EX): 1, 3, 5, 7, 9 and 10 mL of each analyte is added to the respective flasks above while accurately recording the masses.

9.1.2.3 For toluene (T): 1, 3, 5, 7, 10, 15 mL aliquots are added to respective flasks above (that is, least concentrated toluene is in solution with least concentrated ethylbenzene and xylenes-EX) while accurately recording the masses.

9.1.2.4 For benzene (B): 0.10 mL, 0.30 mL, 0.50 mL, 1 mL, 2 mL, 3 mL of benzene are weighed into respective 100 mL flasks or vials (that is, least concentrated benzene is in solution with least concentrated TEX above).

9.1.2.5 The flasks or vials are then filled to 100 mL with n-heptane. This procedure generates calibration solutions containing increasing amounts of benzene from 0.1 to 3 volume %, toluene from 1 to 15 volume %, and ethylbenzene and m, p, and o-xylenes each from 1 to 10 volume % with the internal standard (DME) at a constant 10 volume %.

9.1.3 C9 Aromatics (Table 3/Set B):

9.1.3.1 Add 0.5, 1.0, 2.0, 3.0, 5 mL of each of the C9-aromatics in Table 2 to the respective five flasks or vials (that is, add all of the 0.5 mL concentrations together in flask one, all of the 1.0 mL concentrations to flask two, and so forth) while accurately recording the masses.

9.1.3.2 Add 10.0 mL of DME to each of the five flasks or vials and record the mass of DME.

9.1.3.3 The flasks or vials are then filled to 100 mL with n-heptane. This procedure generates calibration solutions for the C9 aromatics in the range of 0.5 to 5 volume %.

9.1.4 C10 + Aromatics (Table 3/Set C):

9.1.4.1 Add 0.5, 1.0, 2.0, 3.0, 4 mL or grams, if solids, of each of the C10-aromatics in Table 2 to the respective five flasks or vials (that is, add all of the 0.5 mL concentrations together in flask one, all of the 1.0 mL concentrations to flask two, etc.) while accurately recording the masses.

9.1.4.2 Add 10.0 mL of DME to each of the five flasks or vials and record the mass of DME.

9.1.4.3 The flasks or vials are then filled to 100 mL with toluene. This procedure generates calibration solutions for the C10 aromatics in the range of 0.5 to 4 volume %.

9.1.4.4 Ensure that all of the prepared standards are thoroughly mixed and transfer approximately 2 mL of the solution to a vial compatible with the autosampler. Chill the vials until ready for loading on the autosampler.

9.2 GC/FTIR Procedure:

9.2.1 Before initiating the calibration procedure ensure that the GC/FTIR system has been set up according to the manufacturer's instructions.

9.2.2 The WCOT must meet the resolution requirements described in Table 4 when installed in the GC/FTIR system.

9.2.3 Prepare a solution of 0.01 mass % of naphthalene and ensure that it is detected with at least a signal/noise ratio of five.

9.2.4 Sequentially analyze all of the calibration standards.

9.2.5 Table 5 gives suggested operating conditions.

9.3 Calibration Calculations:

9.3.1 After the analyses of the calibration standards is complete, the GC/FTIR is calibrated by generating the selective reconstruction chromatograms for each analyte and the internal standard from the frequency ranges in Table 6. These GC peaks are integrated and calibration curves for each analyte are obtained.

9.3.2 Plot the response ratio rspi:

rspi = (Ai/As)

where:

Ai = area of aromatic compound "i", and

As = area of internal standard.

as the y-axis versus the amount ratio amti:

amti = Wi/Ws

where:

Wi = mass of aromatic compound "i" in the calibration standard, and

Ws = mass of internal standard in the calibration standard.

as the x-axis to generate calibration curves for each oxygenate and aromatic component in Table 1 and Table 2.

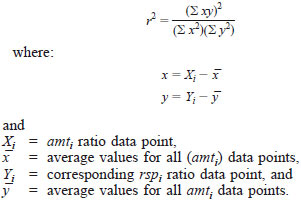

9.3.3 Check the correlation r2 value for each aromatic calibration. The value r2 should be at least 0.99 or better and is calculated as follows:

Table 7 gives an example of the calculation for an ideal data set Xi and Yi.

9.3.4 Linear Least Squares Fit - For each aromatic "i" calibration data set, obtain the linear least squares fit equation in the form:

(rspi) = (mi)(amti) + bi

where:

rspi = response ratio for aromatic "I" (y-axis),

mi = slope of linear equation for aromatic "I",

amti = amount ratio for aromatic "I" (x-axis), and

bi = y-axis intercept.

The values mi and bi are calculated as follows:

Therefore, the least square equation for the above example in Table 7 is:

(rspi) = 0.5(amti) + 0

NOTE 3 - Normally the bi term is not zero and may be positive or negative.

9.3.4.1 The calibration response for benzene with a MCT detector may be nonlinear. In the round robin of this test method a linear fit was used for concentrations up to approximately one mass % benzene and a point to point or quadratic fit used for higher concentrations. The region of linearity may vary among instrument types and needs to be determined during calibration.

9.3.5 Y-intercept Criteria - For an optimum calibration, the absolute of the y-intercept bi must be at a minimum, that is, the calibration curves must not deviate significantly from a y-intercept equal to zero value. Ai approaches zero when wi is less than 0.1 mass %. As Ai approaches zero, the equation to determine the mass % aromatics reduces to Eq 12. Therefore, the y-intercept can be tested using Eq 12:

wi = (bi/mi)(Ws/Wg)100 %

where:

wi = mass % aromatic "I", where wi is <0.1 mass %,

Ws = mass of internal standard added to the gasoline samples for the quantitation of the aromatic component "i", g, and

Wg = mass of gasoline samples, g.

NOTE 4 - Since in practice Ws and Wg vary slightly from sample to sample, typical values for these parameters are used to test the y-intercept.

9.3.6 The GC/FTIR system must be recalibrated whenever results of the quality control reference material do not agree within the tolerance levels specified in 11.1.