11. Report (See Annex A2 for Report Format)

11.1 Report the raw data of the calibration and the analysis of the NIST reference oil SRM1085a.

11.2 Report concentrations of copper, lead, and tin in oil before and after adjustment based on the internal standard, and the difference (C in 10.3).

11.2.1 Report the corrected change in lead concentration (CLead Corrected in 10.3.1), and the applied correction factor (0.276), for non-reference oils.

11.3 Report the tarnish rating of the copper coupon based on the highest rating (most corrosion) if the rating is different for either side.

11.4 Report the change in weight of each of the coupons in mg/cm2.

12. Precision and Bias

12.1 Precision - The precision of the test method was determined by performing round robin tests in seven participating labs in accordance with guidelines set in Practice E 691.

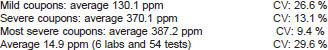

12.1.1 Lead - Precision was established at three severity levels with 7 labs and 21 tests at each level:

12.1.2 Copper:

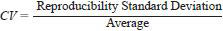

NOTE 4 - CV is the coefficient of variance and is obtained by the following equation:

where:

Reproducibility Standard Deviation is defined in Practice E 691.

13. Keywords

13.1 corrosion; diesel engines; lubricants; wear