ASTM D5966 Standard Test Method for Evaluation of Engine Oils for Roller Follower Wear in Light-Duty Diesel Engine

1. Scope

1.1 This engine lubricant test method is commonly referred to as the Roller Follower Wear Test. Its primary result, roller follower shaft wear in the hydraulic valve lifter assembly, has been correlated with vehicles used in stop-and-go delivery service prior to 1993.3 It is one of the test methods required to evaluate lubricants intended to satisfy the API CG-4 performance category. This test has also been referred to as the 6.2 L Test.

1.2 The values of units used in this test method are stated in either inch-pound units or SI units and are to be regarded separately as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

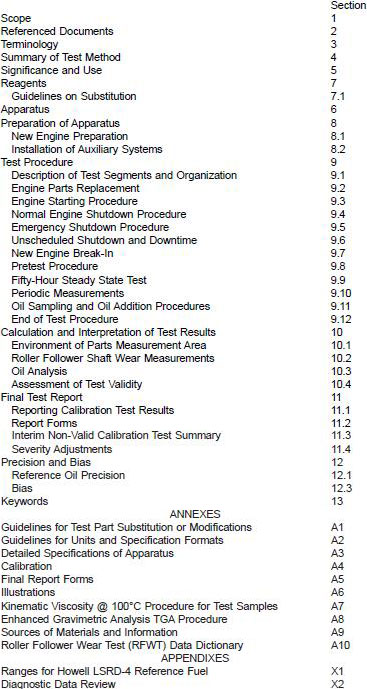

1.4 A Table of Contents follows.

2. Referenced Documents

2.1 ASTM Standards:

D86 Test Method for Distillation of Petroleum Products

D92 Test Method for Flash and Fire Points by Cleveland Open Cup

D97 Test Method for Pour Point of Petroleum Products

D130 Test Method for Detection of Copper Corrosion from Petroleum Products by the Copper Strip Tarnish Test

D235 Specification for Mineral Spirits (Petroleum Spirits) (Hydrocarbon Dry Cleaning Solvent)

D287 Test Method for API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and the Calculation of Dynamic Viscosity)

D446 Specifications and Operating Instructions for Glass Capillary Kinematic Viscometer

D482 Test Method for Ash from Petroleum Products

D524 Test Method for Ramsbottom Carbon Residue of Petroleum Products

D613 Test Method for Cetane Number of Diesel Fuel Oil

D1319 Test Method for Hydrocarbon Types in Liquid Petroleum Products by Fluorescent Indicator Adsorption

D2500 Test Method for Cloud Point of Petroleum Products

D2622 Test Method for Sulfur in Petroleum Products by X-Ray Spectrometry

D2709 Test Method for Water and Sediment in Distillate Fuels by Centrifuge

D4175 Terminology Relating to Petroleum, Petroleum Products, and Lubricants

D4485 Specification for Performance of Engine Oils

D4737 Test Method for Calculated Cetane Index by Four Variable Equation

D5185 Test Method for Determination of Additive Elements, Wear Metals, and Contaminants in Used Lubricating Oils and Determination of Selected Elements in Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry

D5186 Test Method for Determination of Aromatic Content of Diesel Fuels by Supercritical Fluid Chromatography

D5302 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Deposit Formation and Wear in a Spark-Ignition Internal Combustion Engine Fueled with Gasoline and Operated Under Low-Temperature, Light-Duty Conditions

D5844 Test Method for Evaluation of Automotive Engine Oils for Inhibition of Rusting (Sequence IID)

E 29 Practice for Using Significant Digits in Test Data to Determine Conformance With Specifications

E 344 Terminology Relating to Thermometry and Hydrometry

2.2 Society of Automotive Engineers (SAE):

SAE J183 Engine Oil Performance and Engine Service Classification

SAE J726 Air Cleaner Test Code (Includes Piezometer Ring Specifications)

2.3 American Petroleum Institute (API):

API 1509 Oil Licensing and Certification System

2.4 American National Standards Institute (ANSI):

MC96.1 Temperature Measurement Thermocouples

3. Terminology

3.1 Definitions:

3.1.1 blowby, n - in internal combustion engines, the combustion products and unburned air-and-fuel mixture that enter the crankcase.

3.1.2 BTDC, adj - abbreviation for Before Top Dead Center, used with the degree symbol to indicate the angular position of the crankshaft relative to its position at the point of uppermost travel of the piston in the cylinder.

3.1.3 calibrate, v - to determine the indication or output of a measuring device with respect to that of a standard.

3.1.4 candidate oil, n - an oil which is intended to have the performance characteristics necessary to satisfy a specification and is tested against that specification.

3.1.5 engine oil, n - a liquid that reduces friction or wear, or both, between the moving parts within an engine; removes heat, particularly from the underside of pistons; and serves as a combustion gas sealant for piston rings.

3.1.5.1 Discussion - It may contain additives to enhance certain properties. Inhibition of engine rusting, deposit formation, valve train wear, oil oxidation and foaming are examples.

3.1.6 light-duty, adj - in internal combustion engine operation, characterized by average speeds, power output, and internal temperatures that are generally much lower than the potential maximums.

3.1.7 light-duty engine, n - in internal combustion engine types, one that is designed to be normally operated at substantially less than its peak output.

3.1.8 lubricant, n - any material interposed between two surfaces that reduces friction or wear, or both, between them.

3.1.9 lubricating oil, n - a liquid lubricant, usually comprising several ingredients, including a major portion of base oil and minor portions of various additives.

3.1.10 reference oil, n - an oil of known performance characteristics, used as a basis for comparison.

3.1.10.1 Discussion - Reference oils are used to calibrate testing facilities, to compare the performance of other oils, or to evaluate other materials (such as seals) that interact with oils.

3.1.11 used oil, n - any oil that has been in a piece of equipment (for example, an engine, gearbox, transformer, or turbine), whether operated or not.

3.1.12 wear, n - the loss of material from, or reduction of material on, a surface.

3.1.12.1 Discussion - Wear generally occurs between two surfaces moving relative to each other, and is the result of mechanical or chemical action or a combination of both.