12. Report

12.1 Report the temperature recorded in 11.9 together with the testing interval as pour point Test Method D5949.

13. Precision and Bias

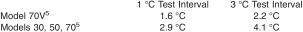

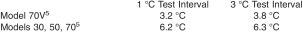

13.1 Precision - The precision of this test method as determined by the statistical examination of the interlaboratory test results is as follows:

13.1.1 Repeatability - The difference between successive test results, obtained by the same operator using the same apparatus under constant operating conditions on identical test material, would in the long run, in the normal and correct operation of this test method, exceed the following values only in one case in twenty.

13.1.2 Reproducibility - The difference between two single and independent test results, obtained by different operators working in different laboratories on identical test material, would in the long run, in normal and correct operation of this test method, exceed the following values only in one case in twenty.

13.2 Bias - Since there is no accepted reference material suitable for determining the bias for the procedure in this test method, bias has not been determined.

13.3 Relative Bias:

13.3.1 Pour points at 3 °C testing intervals were compared to the results from Test Method D97. Relative bias among certain samples was observed; however, the observed bias does not appear to be of a systematic nature. Biases relative to Test Method D97/IP 15 may conceivably occur for sample types not included in the 1998 interlaboratory test program.

NOTE 4 - Large differences in results were observed between methods for one sample in the 1998 interlaboratory test study. The sample was a high-sulfur winter diesel. When cooled during the performance of a test method, this sample formed thin, but very large, crystals, that could be described as large plates. These crystals formed wherever sample-glass contact was made as well as covered the top surface of the sample. The entire sample, except for this all encasing thin skin of crystals, remained liquid with apparent low viscosity. When this occurred and the sample was handled gently, the sample did not pour, but with rougher handling, the crust broke and the sample poured readily. Users of this test method are advised to be alert for differences in results between test methods when this behavior is observed in the sample being tested.

13.3.2 Pour point results at 1 °C testing intervals were examined for bias relative to the pour point results at 3 °C intervals. A bias of 1.1 °C on average was observed.

13.3.2.1 It shall be noted that when a specimen is tested at 1 °C intervals, statistically the results will be 1 °C lower than the results produced by 3 °C testing intervals. This is due to test increment and reporting differences. Differences greater than 1 °C over a number of samples would be from another cause. In the interlaboratory test program, the tests at 1 °C intervals yielded a pour point lower than those obtained from the tests at 3 °C intervals by 1.1 °C in average.

13.4 The precision statements and the relative bias information were derived from a 1998 interlaboratory test program. Participants analyzed two sets of duplicate diesel fuel oils, five sets of duplicate base oils, three sets of duplicate multigrade lubricating oils, and one set each of duplicate hydraulic oils and automatic transmission fluid in the temperature range from -51 °C to -11 °C. Nine laboratories participated with the Models 30, 50, 70 apparatus and six laboratories participated with the Model 70V, all testing at 1 °C and 3 °C intervals. Seven laboratories participated with the manual Test Method D97 apparatus. Information on the types of samples and their average pour points are in the research report available at ASTM International Headquarters.

13.5 Relative Bias Between Models 70V and 70X - The statistical analysis by Practice D6708 of between-method bias indicates the following statistical bias between the average results of the models of instruments.

13.5.1 For 3 °C interval, no correction can statistically improve agreement between 70V and 70X.

13.5.2 For 1 °C interval, the degree of agreement from Models 70V and Models 70X can be further improved by applying a constant bias-correction outlined in Eq 1.

X = Y - 2.5

where:

X = 70V Models result in °C, and

Y = 70X Models result in °C.

13.6 Participants in 2013 analyzed two sets of duplicate diesel fuel oils, two sets of duplicate base oils, and two sets of duplicate formulated lubricating oils. Four laboratories participated with the Models 70V apparatus and eight laboratories participated with the Model 70X, all testing at 1 °C and 3 °C intervals. Information on the types of samples and their average pour points are in the research report available at ASTM International Headquarters.

14. Keywords

14.1 Peltier; petroleum products; pour point; pressure pulsing; thermoelectric