10. Calculation and Report

10.1 Add 3°C to the temperature recorded in 9.1.8 and report as Maximum Pour Point, ASTM D5853, Procedure A, or Minimum Pour Point, ASTM D5853, Procedure B, if the procedure in 9.2 has been followed.

10.2 If the test was discontinued (9.1.8.1), report the pour point as not more than -36°C.

11. Precision and Bias

11.1 The following criteria are to be used for judging the acceptability of results (95 % confidence):

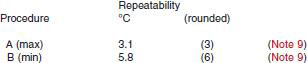

11.1.1 Repeatability - The difference between successive test results obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following value only in 1 case in 20.

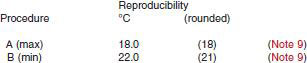

11.1.2 Reproducibility - The difference between two, single and independent results, obtained by different operators working in different laboratories on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the following value only in 1 case in 20.

NOTE 9 - These precision values are derived from a 1994 cooperative program and the current Committee D-2 Statistical Method, RR:D02-1007. A summary of the cooperative program and the relevant statistics is given in Appendix X2.

11.2 Bias - The procedure in this test method has no bias because the value of pour point is defined only in terms of this test method.

12. Keywords

12.1 cold flow; crude oil; pour point