6. Apparatus

6.1 Pour Point Test Apparatus Assembly (see Fig.1):

6.1.1 Test Jar, cylindrical, of clear glass, flat bottomed, outside diameter 33.2 to 34.8 mm, and height 115 to 125 mm. The inside diameter of the jar can range from 30.0 to 32.4 mm, within the constraint that the wall thickness shall be no greater than 1.6 mm. The jar shall have a line to indicate a sample height 54 +/- 3 mm above the inside bottom. The inside of the test jar (up to the mark) shall be visibly clean and free of scratches.

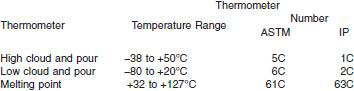

6.1.2 Thermometers, having ranges shown in the following table and conforming to the requirements prescribed in Specification E 1 for thermometers:

6.1.2.1 Since separation of liquid column thermometers occasionally occurs and may escape detection, the ice point of the thermometers shall be checked prior to the test and used only if they are accurate within +/-1°C (see Test Method E 77).

6.1.3 Cork, to fit the test jar, center bored for the test thermometer.

6.1.4 Jacket, watertight, cylindrical, metal, flat bottomed, 115 +/- 3 mm depth, with inside diameter of 44.2 to 45.8 mm. It shall be supported in a vertical position in the cooling bath (6.1.7) so that no more than 25 mm projects out of the cooling medium. The jacket shall be capable of being cleaned.

6.1.5 Disk, cork or felt, 6 mm thick to fit loosely inside the jacket.

6.1.6 Gasket, to fit snugly around the outside of the test jar and loosely inside the jacket. The gasket shall be made of rubber, leather, or other material that is sufficiently elastic to cling to the test jar and hard enough to hold its shape. Its purpose is to prevent the test jar from touching the jacket.

6.1.7 Cooling Bath or Baths, of a type suitable for obtaining the required temperatures. The size and shape of the bath are options, but a support to hold the jacket firmly in a vertical position is essential. The bath temperature shall be monitored by means of the appropriate thermometer (6.1.2) or any other temperature measuring device capable of measuring and displaying the designated temperature with the required precision and accuracy. The required bath temperatures shall either be maintained by refrigeration or by suitable freezing mixtures (Note 1) and shall maintain the designated temperatures to within +/-1.5°C.

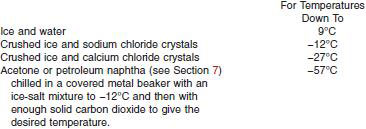

NOTE 1 - The cooling mixtures commonly used are as follows:

6.2 Water Bath - The size and shape of the bath are optional, but a support to hold the test jar immersed in the bath to above the sample height in the test jar and in a firm vertical position is required. The required bath temperature may be maintained by any suitable means, provided the temperature can be monitored and controlled to the designated temperature (+/-1°C (9.1.4; 9.2.4)).

6.3 Pressure Vessel, constructed of stainless steel according to the dimensions given in Fig. 2, and capable of withstanding a test pressure of 700 kPa. Alternative designs for the pressure vessel cap and synthetic rubber gasket may be used provided that the internal dimensions of the pressure vessel are the same as those shown in Fig. 2.

6.4 Timing Device, capable of measuring up to 30 s with a resolution of at least 0.1 s and an accuracy of +/-0.2 s or better.

7. Reagents and Materials

7.1 The following solvents of technical grade are appropriate for low-temperature bath media.

7.1.1 Acetone, (Warning - Extremely flammable.)

7.1.2 Alcohol, Ethanol, (Warning - Flammable.)

7.1.3 Alcohol, Methanol, (Warning - Flammable. Vapor harmful.)

7.1.4 Petroleum Naphtha, (Warning - Combustible. Vapor harmful.)

NOTE 2 - Typical petroleum naptha used for cleaning purposes are VM and P napthas.

7.2 Toluene, technical grade (Warning - Flammable. Vapor harmful.).

7.3 Solid Carbon Dioxide, (Warning - Extremely cold (-78.5°C).)

8. Sampling, Test Samples, and Test Specimens

NOTE 3 - Sampling is defined as all steps required to obtain a portion of the contents of any pipe, tank, or other system and to place the sample into the laboratory test container.

8.1 Laboratory Sample - It is essential that the sample received by the laboratory is representative of the batch or lot of crude oil from which it was taken. Practices D4057 and D4177 provide guidance for obtaining such representative samples.

8.2 Preparation of Test Samples - The pour point of crude oils is very sensitive to trace amounts of high melting waxes. Exercise meticulous care to ensure such waxes, if present, are either completely melted or, if volatility constraints prevent heating to complete melting, homogeneously suspended in the sample (Appendix X1). Inspect the walls of the original container to ensure that no high melting point material is left sticking to the wall.

NOTE 4 - It is not possible to define universal mandatory rules for the preparation of crude oil test samples. Guidelines for sample handling for the most common situations are given in Appendix X1.