7. Apparatus

7.1 High-Performance Liquid Chromatograph (HPLC) - The required analytical apparatus, an HPLC, consists of an injection device with sample loop, pumping system capable of mixing at least two solvents, reversed phase analytical column, UV detector or detectors with the ability to operate at a minimum of two wavelengths, and a data recording device or integrator.

7.2 It is recommended that a precolumn packed with the same material as the analytical column be used to increase column life and remove interferences.

7.3 Helium sparging of the mobile-phase solvents is recommended in some cases and with some types of HPLC equipment to displace atmospheric gases dissolved in the mobile-phase solvents and to prevent the evolution of air bubbles.

7.4 The analytical apparatus may be heated several degrees Celsius above ambient if necessary to reduce variance in analytical results that may be caused by temperature fluctuations. Operation at ambient temperature or at a controlled temperature of 30 to 40°C has been found satisfactory by some laboratories.

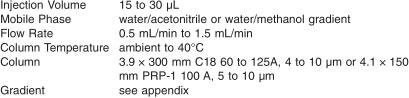

7.5 The following range of HPLC analytical conditions has been found to be satisfactory for extracted test specimens (specific examples are given in the appendix):

NOTE 1 - Some laboratories have found it beneficial to filter all mobile phase solvents with a 0.45-µm or smaller polytetrafluoroethylene or nylon filter. Store water in containers shielded from light. Some laboratories use 50 mL of methanol added to 4 L of water to inhibit biological growth.

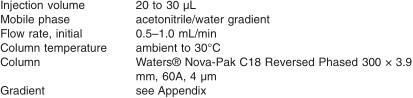

7.6 The following HPLC analytical conditions have been found to be satisfactory for direct injection of the oil:

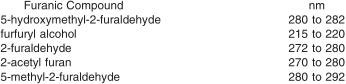

7.7 For direct injection, a fixed wavelength between 274 and 281 nm has been found to provide the best chromatography for all compounds of interest, except furfuryl alcohol, which is best measured with a separate test using a wavelength between 215 and 220 nm. Each furanic compound has a characteristic maximum light absorbance occurring within the indicated ranges of wavelengths. Use of variable wavelength or diode array detectors allows the selection ofa specific wavelength for each furanic compound. Each laboratory shall select the specific wavelength to yield maximum absorbance for each compound as follows:

7.8 After the last compound of interest elutes through the column, increase the acetonitrile or methanol to 100 % of the mobile phase to remove all oil contamination remaining in the analytical column.

7.9 Readjust the solvent ratio of the mobile phase to the initial conditions and allow 10 to 15 min for the column to come to equilibrium prior to the next injection.

8. Reagents and Materials

8.1 Acetonitrile - HPLC grade.

8.2 2-Acetylfuran - 99 % purity, CAS #1192-62-7.

8.3 Electrical Insulating Oil - Virgin oil of mineral origin.

8.4 2-Furaldehyde - 99 % purity, CAS #98-01-1.

8.5 Furfuryl Alcohol - ≥98 % purity, CAS #98-00-0.

8.6 Hexane - HPLC grade.

8.7 5-Hydroxymethyl-2-Furaldehyde - 99 % purity, CAS #67-47-0.

8.8 Methanol - HPLC grade.

8.9 5-Methyl-2-furaldehyde - ≥98 % purity, CAS #620-02-0.

8.10 Silica SPE Column - Solid-phase extraction column filled with 500 mg of silica.

8.11 Toluene - HPLC grade.

8.12 Vacuum Manifold - Device to pull vacuum on solid-phase extraction column in order to pass sample and eluent through SPE column.

8.13 Volumetric Test Tube - Test tube designed to volumetrically measure in 0.10-mL graduations.

8.14 Vortex Mixer.

8.15 Water - HPLC grade.

9. Sampling

9.1 Obtain test specimens (insulating fluid samples) in accordance with the procedures for sampling in Practices D923.