ASTM D5769 Standard Test Method for Determination of Benzene, Toluene, and Total Aromatics in Finished Gasolines by Gas Chromatography/Mass Spectrometry

6. Apparatus

6.1 Gas Chromatography:

6.1.1 System equipped with temperature-programmable gas chromatograph suitable for split injections with WCOT column or cool-on-column injector that allows the injection of small (for example, 0.1 µL) samples at the head of the WCOT column or a retention gap. An autosampler is mandatory for the on-column injections.

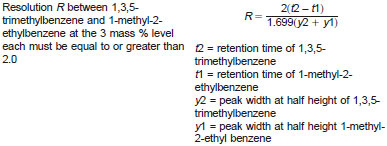

6.1.2 WCOT column containing dimethylpolysiloxane bonded stationary phase, meeting the specification in the following table. For on-column injections, a column containing a thicker film of stationary phase, such as 4–5 µm, is recommended to prevent column sample overload.

6.2 Mass Spectrometry:

6.2.1 Mass spectrometer capable of producing electron impact spectra at 70, or higher, electron volts or equivalent, and capable of scanning the range of the specified quantitation masses or m/e. The mass scan range shall cover the masses of interest for quantitation and should yield at least 5 scans across the peak width at half peak width for a 1 to 3 mass percent toluene and cover the masses of interest for quantitation. A scan range of 41 to 200 daltons is adequate.

6.2.2 The mass spectrometer must be capable of being interfaced to a gas chromatograph and WCOT columns. The interface must be at a high enough temperature to prevent condensation of components boiling up to 220°C, usually 20°C above the final column temperature is adequate. Direct column interface to the mass spectrometer can be used. An open split interface with computer controlled programmable flow controller(s) can also be used, particularly with cool on-column injections, to maintain all aromatic components within the linearity of the mass spectrometer and at the same time maintain detectability of lower concentration aromatic components. For example, a higher open-split-interface make-up gas flow can be used for the high concentration components, such as toluene and xylenes, and a lower make-up gas flow rate may be used during the elution of the lower concentration benzene and C9+ components. Other interfaces may be used provided the criteria specified in Sections 9 and 10 are met.

6.2.3 A computer system shall be interfaced to the mass spectrometer to allow acquisition of continuous mass scans or total ion chromatogram (TIC) for the duration of the chromatographic program and be able to analyze repeatedly 0.01 mass percent 1,4-diethylbenzene with the specified signal/noise ratio of 5. Software must be available to allow searching any GC/MS run for specific ions or reconstructed ions and plotting the intensity of the ions with respect to time or scan number. The ability to integrate the area under a specific ion plot peak is essential for quantitation. The quantitation software must allow linear least squares or quadratic nonlinear regression and quantitation with multiple internal standards. It is also recommended that software be available to automatically perform the identification of aromatic components as specified in 13.1.1.

7. Reagents and Materials

7.1 Carrier Gas - Helium and hydrogen have been used successfully. The recommended minimum purity of the carrier gas used is 99.999 mol percent. Additional purification using commercially available scrubbing reagents may be necessary to remove trace oxygen, which may deteriorate the performance of the GC WCOT. (Warning - Helium and hydrogen are supplied under high pressure. Hydrogen can be explosive and requires special handling. Hydrogen monitors that automatically shut off supply to the GC in case of serious leaks are available from GC supply manufacturers.)

7.2 Dilution Solvents - Reagent grade 2,2,4-trimethylpentane (iso-octane), n-heptane, n-nonane, cyclohexane, or toluene, or a combination thereof, used as a solvent in the preparation of the calibration mixtures. (Warning - The gasoline samples and solvents used as reagents such as iso-octane, cyclohexane, n-heptane, n-octane, and toluene, are flammable and may be harmful or fatal if ingested or inhaled. Benzene is a known carcinogen. Use with proper ventilation. Safety glasses and gloves are required while preparing samples and standards. Samples should be kept in well ventilated laboratory areas.)

NOTE 1 - Toluene should be used as a solvent only for the preparation of C9+ components and shall be free from interfering aromatics.

7.3 Internal Standards - Deuterated analogs of benzene, ethylbenzene, and naphthalene, as specified in Table 1, shall be used as internal standards because of their similar chromatographic characteristics as the components analyzed. The use of a fourth internal standard toluene-d8 is recommended. Deuterated naphthalene is hygroscopic and should be stored away from high humidity.

7.4 Standards for Calibration and Identification - Aromatic hydrocarbons used to prepare standards should be 99 % or greater purity (see Table 1). If reagents of high purity are not available, an accurate assay of the reagent shall be performed using a properly calibrated GC or other techniques. The concentration of the impurities that overlap the other calibration components shall be known and used to correct the concentration of the calibration components. The use of only high purity reagents is strongly recommended because of the error that may be introduced from impurity corrections. Standards are used for calibration as well as for establishing the identification by retention time in conjunction with mass spectral match (see 13.1.1). Naphthalene is hygroscopic and should be stored away from high humidity.

8. Sampling

8.1 Every effort should be made to ensure that the sample is representative of the fuel source from which it is taken. Follow the recommendations of Practice D4057, or its equivalent, when obtaining samples from bulk storage or pipelines. Sampling to meet certain regulatory specifications may require the use of specific sampling procedures. Consult appropriate regulations.

8.2 Appropriate steps should be taken to minimize the loss of light hydrocarbons from the gasoline sample while sampling and during analyses. Upon receipt in the laboratory, chill the sample in its original container to between 0 to 5°C (32 to 40°F) before and after a sample aliquot is removed for analysis.

8.3 After the sample is prepared for analysis with internal standard(s), chill the sample and fill the autosampler vial to approximately 90 % of its volume. The remainder of the sample should be re-chilled immediately and protected from evaporation for further analyses, if necessary. To prevent evaporation of the sample, the autosampler vials should be stored at 0 to 5°C (32 to 40°F) until ready for loading on the autosampler.