ASTM D5599 Standard Test Method for Determination of Oxygenates in Gasoline by Gas Chromatography and Oxygen Selective Flame Ionization Detection

13. Quality Control Checks

13.1 Routinely monitor the intralaboratory repeatability and accuracy of the analysis as follows:

13.1.1 Intralaboratory Repeatability:

13.1.1.1 Quality control check standards may be prepared from the same oxygenate stocks prepared in 10.2 and covering the range given in 13.1.1.4.

13.1.1.2 Prepare and analyze duplicates of the quality control check standards at a rate of one per analysis batch or at least one per ten samples, whichever is more frequent.

13.1.1.3 Duplicates should be carried through all sample preparation steps independently.

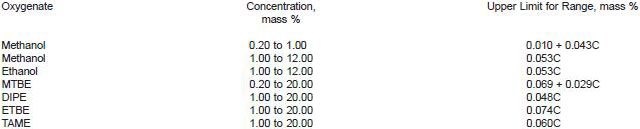

13.1.1.4 The range (R) for duplicate samples should be less than the following limits:

where:

C = (Co + Cd)/2

R = (Co - Cd)

Co = concentration of the original sample, and

Cd = concentration of the duplicate sample.

13.1.2 If these limits are exceeded, the sources of error in the analysis should be determined, corrected, and all analyses subsequent to and including the last duplicate analysis confirmed to be within the compliance specifications should be repeated.

13.2 Intralaboratory Accuracy:

13.2.1 If the measured concentration of a quality control check standard is outside the range of 100.0 +/- 6.0 % of the theoretical concentration for a selected oxygenate of 1.0 mass % or above, the sources of error in the analysis should be determined, corrected, and all analyses subsequent to and including the last standard analysis confirmed to be within the compliance specifications should be repeated.

13.2.2 Independent reference standards may be purchased or prepared from materials that are independent of the quality control standards and should not be prepared by the same analyst. For the specification limits listed in 13.2.2.2, the concentration of the reference standards should be in the range given in 13.1.1.4.

13.2.2.1 Independent reference standards should be analyzed at a rate of one per analysis batch or at least one per 100 samples, whichever is more frequent.

13.2.2.2 If the measured concentration of an independent reference standard is outside the range of 100.0 +/- 10.0 % of the theoretical concentration for a selected oxygenate of 1.0 mass % or above, the sources of error in the analysis should be determined, corrected, and all analyses subsequent to and including the last independent reference standard analysis confirmed to be within the compliance specifications in that batch should be repeated.

13.3 Control charts may be utilized to monitor the variability of measurements from the quality control check standards and independent reference standards in order to optimally detect abnormal situations and ensure a stable measurement process.