ASTM D5580 Standard Test Method for Determination of Benzene, Toluene, Ethylbenzene, p/m-Xylene, o-Xylene, C9 and Heavier Aromatics, and Total Aromatics in Finished Gasoline by Gas Chromatography

11. Calibration

11.1 Preparation of Calibration Samples - Prepare multi-component calibration standards of benzene, toluene, ethylbenzene, o-xylene, and 1,2,4-trimethylbenzene at concentrations of interest by mass in accordance with Practice D4307. O-xylene is used to represent the xylenes while 1,2,4-trimethylbenzene is used for the C9 and heavier aromatics. For each aromatic component, use at least five calibration points and ensure that the concentration of each aromatic component is within its calibration range. For benzene, calibration concentrations of 0.1, 0.5, 1.0, 2.0, and 5 volume percent can be used. For toluene: 1.0, 2.5, 5.0, 10.0, and 15.0 volume %. For ethylbenzene, o-xylene, and 1,2,4-trimethylbenzene: 0.5, 1.0, 2.5, 5.0, and 10 volume % can be used. The relative densities listed in Table 2 shall be used as a guide in determining the proper mass of aromatic components that need to be added in order to arrive at a target volume percent concentration.

11.2 Before preparing the standards, determine the purity of the aromatics by capillary GC and make corrections for the impurities found. Whenever possible, use stocks of at least 99.9 % purity.

11.3 Prepare standards by transferring a fixed volume of aromatic component using pipettes, eye droppers, or syringes to 100-mL volumetric flasks or 100-mL septum-capped vials as follows. Cap and record the tare weight of the volumetric flask or vial to 0.1 mg. Remove the cap and carefully add the aromatic components to the flask or vial starting with the least volatile (1,2,4-trimethylbenzene). Cap the flask and record the net mass (Wi) of the aromatic component added to 0.1 mg. Repeat the addition and weighing procedure for each aromatic component. Do not exceed 50 volume % for all aromatics added. Similarly, add 10 mL of the internal standard, 2-hexanone, and record its net mass ( Ws) to 0.1 mg. Dilute each standard to the mark with aromatics free 2,2,4-trimethylpentane (isooctane). Store the capped calibration standards in a refrigerator at 0 to 5°C (32 to 40°F) when not in use.

11.4 Calibration Procedure - With the valve initially in the RESET mode, chromatograph each of the calibration mixtures (11.1) twice using valve timing procedures in accordance with 10.5. For the first analysis use times T1 (BACKFLUSH) and T3 (RESET) to actuate the valve. For the second analysis use times T2 (BACKFLUSH) and T4 (RESET) to actuate the valve.

NOTE 2 - The first analysis is used to calibrate the gas chromatograph for benzene and toluene. The second analysis is used to calibrate for ethylbenzene, the xylenes (o-xylene), and the C9 and heavier aromatics (1,2,4-trimethylbenzene).

11.4.1 Linearity Test - Analyze the calibration standards in accordance with the procedure in 11.4. Measure the peak areas of benzene, toluene, and internal standard peaks from the first analysis. From the second analysis measure the peak areas of internal standard, ethylbenzene, o-xylene, and 1,2,4-trimethylbenzene. Determine the response ratio (rspi) and amount ratio (amti) for each component in each standard using Eq 2 and Eq 3.

rspi = (Ai/As)

where:

Ai = area of aromatic component, and

As = area of internal standard.

amti = (Wi/Ws)

where:

Wi = mass of aromatic component, and

Ws = mass of internal standard.

11.4.1.1 Prepare a calibration curve for each aromatic component by plotting the response ratios (rspi), as the y-axis, versus the amount ratios (amti), as the x-axis. Fig. 3 is an example of such a plot.

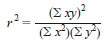

11.4.1.2 Calculate the correlation coefficient r2 value for each aromatic component in the calibration using Eq 4. The r2 value should be at least 0.990 or greater. If the above criteria for r2 is not met, rerun the calibration or check instrument parameters and hardware.

where:

11.4.1.3 Table 3 gives an example on the calculation of r2 for an ideal data set.

11.4.2 Linear Least Square Fit - For each aromatic i calibration data set, obtain the linear least square fit equation in the form:

(rspi) = (mi)(amti) + bi

where:

rspi = response ratio for aromatic i ( y-axis),

mi = slope of linear equation for aromatic i,

amti = amount ratio for aromatic i (x-axis), and

bi = y-axis intercept.

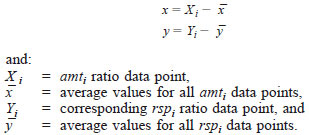

11.4.2.1 The values mi and bi are calculated as follows:

and:

11.4.2.2 For the example in Table 3

mi = 5/10 = 0.5

and

bi = 1.5 - (0.5)(3) = 0

11.4.2.3 Therefore, the least square equation (Eq 7) for the example in Table 3 is:

(rspi) = 0.5(amti) + 0

NOTE 3 - Normally the bi value is not zero and can be positive or negative. Fig. 3 gives an example of linear least square fit for benzene and the resulting equation in the Eq 7.

11.4.3 Y-Intercept Test - For an optimum calibration, the absolute value of the y-intercept (bi) must be at a minimum. In this case, Ai approaches zero when wi is less than 0.1 mass %. In practice, this means the mass % (wi) calculated for an aromatic with zero peak area must be close to zero. The equation to determine the mass % aromatic i, or wi, reduces to Eq 13. The y-intercept can be tested using 13 below:

wi = (bi/mi)(Ws/Wg)100 %

where:

wi = mass % aromatic i,

Ws = mass of internal standard added, g, and

Wg = mass of gasoline samples, g.

NOTE 4 - Since in practice Ws and Wg vary slightly from sample to sample, use an average value as indicated below.

For benzene, wi must be less than 0.02 mass %. For the other aromatics, wi must be less than 0.2 mass %. If any of the wi values exceed the mass % limit, rerun the calibration procedure for aromatic i, or check instrument parameters and hardware.

The following gives an example of the calculation for the y-intercept (bi) test using the data from Fig. 3 for aromatic i(benzene) for which bi = 0.0018 and mi = 1.41. From 13.1, a typical sample preparation may contain approximately Ws = 0.8 g (1.0 mL) of internal standard and Wg = 6.75 g (9.0 mL) of a gasoline sample. Substituting these values into Eq 13 yields:

wi = (0.0018/1.41)(0.8/6.75)100 %

wi = 0.01 mass %

Since wi is less than 0.02 mass% , the y-intercept (bi) has an acceptable value for benzene. Similarly, determine wi for all other aromatics.

12. Column Conditioning

12.1 Both the TCEP and WCOT columns are to be briefly conditioned before use. Connect the columns to the valve (see Fig. 1 and 10.1) in the chromatographic oven. Adjust the carrier gas flows in accordance with 10.3 and place the valve in the RESET position. After several minutes, increase the column oven temperature to 120°C and maintain these conditions for 20 min. Cool the columns below 60°C before shutting off the carrier gas.