9. Preparation of Apparatus

9.1 Column Conditioning - Capillary columns with bonded (or cross-linked) stationary phases do not normally need to be conditioned; however, it is good chromatographic practice to briefly condition a new column as described below.

9.1.1 Install the column in the chromatographic oven and connect one column end to the sample inlet system. Turn on the source of carrier gas and set the flow controller (or pressure regulator) to the flow rate to be used in the analysis. Increase the column temperature to the maximum value to be used in the analysis and maintain this temperature for 30 min. Cool the column temperature to room temperature and connect the remaining column end to the detector. Care must be taken that the column terminates as close as possible to the tip of the FID jet. The temperature of the column between the column oven and the detector jet must be maintained above the maximum column temperature.

9.2 Operating Conditions - Set the chromatographic operating conditions (see Table 1) and allow the system to achieve all temperature setpoints. The recorder, computer or integrating device should be connected so that a plot of the detector signal versus time can be obtained. Make certain that the FID is ignited before proceeding.

9.3 Baseline Blank - After conditions have been set to meet performance requirements, program the column temperature upward to the maximum temperature to be used. Once the column oven temperature has reached the maximum temperature, cool the column to the selected starting temperature. Without injecting a sample, start the column temperature program, the recording device and the integrator. Make two baseline blank runs to determine if the baseline blank is repeatable. If the detector signal is not stable or if the baseline blanks are not repeatable, then the column should either be conditioned further or replaced.

9.3.1 Baseline Bleed - Observe the detector response from the blank run on the recorder. Some increase in detector response will be observed at the upper column temperatures due to stationary phase bleed. Column bleed is acceptable so long as the duplicate baseline blank analyses are repeatable. The baseline should be a smooth curve, free of any chromatographic peaks.

9.4 Solvent Blank - Make a 1-µL injection of the cyclohexane solvent and program the column oven. The solvent is of suitable purity if there are no detected peaks within the retention time range over which the wax samples elute.

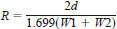

9.5 Column Resolution - Check the efficiency of the GC column by analyzing, under conditions specified in 10.2, a 1-µL injection of 0.05 mass % solution of n-C20 and n-C24 in cyclohexane. The column resolution must not be less than 30 as calculated using Eq 2.

where:

d = distance (mm) between the peak maxima of n-C20 and n-C24,

W1 = peak width (mm) at half height of n-C20, and

W2 = peak width (mm) at half height of n-C24.

9.6 Linearity of Response - For quantitative accuracy, detector response must be proportional to the mass of hydrocarbon injected, and the response of the non-normal paraffins is assumed to be equivalent to the response of the n-paraffin with the same carbon number. In addition, sample injection technique and sample solution properties must be such that representative sample is introduced to the gas chromatograph without discrimination. Before use, the analysis system must be shown to conform to these requirements as specified in 9.6.1.

9.6.1 Analyze the linearity standard described in 7.5 and calculate the relative mass response factors according to Practice D4626. Response factors calculated relative to hexadecane must be between 0.90 and 1.10.

9.6.2 If relative response factors are not within the limits stated above, take appropriate action and reanalyze the linearity standard to ensure linearity and the absence of discrimination.

9.7 Retention Time Repeatability - Check the retention time repeatability by analyzing the linearity standard in duplicate. Retention times for duplicate analyses must not differ by more than 0.10 min between duplicate runs.

10. Calibration and Standardization

10.1 n-Paraffin Identification - Determine the retention time of each n-paraffin in the range from C16 to C44 by injecting small amounts of each paraffin either separately or in known mixtures. Completely dissolve samples in cyclohexane.

10.2 Standardization - Inject the linearity standard described in 7.5 and measure the peak area of each n-paraffin by electronic integrator or computer.

10.2.1 Calculate the response per unit mass of the detector for each component in the linearity standard, relative to n-C16, according to Practice D4626.