6. Apparatus

6.1 Chromatograph - Any gas chromatographic instrument that can accommodate a WCOT column, equipped with a flame ionization detector (FID), and that can be operated at the conditions given in Table 1 may be employed. The chromatograph should be equipped with a cool on-column inlet (or equivalent) for introducing appropriate quantities of sample without fractionation. In addition, the gas chromatograph must be capable of generating a chromatogram where the retention times of an individual peak have retention time repeatability within 0.1 min. Refer to Practices E 260 and E 355 for general information on gas chromatography.

6.2 Sample Introduction System - Any system capable of introducing a representative sample onto the front portion of a WCOT column may be employed. Cool on-column injection is preferred, however other injection techniques can be used provided the system meets the specification for linearity of response in 9.6. For cool on-column injection, syringes with 0.15 to 0.25-mm outside diameter needles have been used successfully for columns 0.25-mm inside diameter or larger and standard 0.47-mm outside diameter syringe needles have been used for columns 0.53-mm inside diameter or greater.

6.2.1 Care must be taken that the sample size chosen does not allow some peaks to exceed the linear range of the detector or overload the capacity of the column.

6.3 Column(s) - Any column used must meet the chromatographic resolution specification in 9.5. WCOT columns with 25 to 30-m lengths and a stationary phase coating of methyl siloxane or 5 % phenyl methyl siloxane have been successfully used. Cross-linked or bonded stationary phases are preferred.

6.4 Recorder - A recording potentiometer or equivalent with a full-scale deflection of 5 mV or less for measuring the detector signal versus time. Full scale response time should be 2 s or less. Sensitivity and stability should be sufficient to generate greater than 2-mm recorder deflection for a hydrocarbon injection of 0.05 mass % under the analysis conditions employed.

6.5 Integrator or Computer - Means must be provided for integrating the detector signal and summing the peak areas between specific time intervals. Peak areas can be measured by computer or electronic integration. The computer, integrator, or gas chromatograph must have the capability of subtracting the area corresponding to the baseline (blank) from the sample area, and have the ability to draw the baselines used for peak area integration.

7. Reagents and Materials

7.1 Carrier Gas - Carrier gas appropriate for the flame ionization detector. Hydrogen and helium have been used successfully. The minimum purity of the carrier gas used should be 99.95 mol %. (Warning - Hydrogen and helium are compressed gases under high pressure. Hydrogen is an extremely flammable gas.)

7.2 n-hexadecane - Hydrocarbon to be added to samples as an internal standard. Minimum purity of 98 % is required.

7.3 Standards for Calibration and Identification - Standard samples of normal paraffins covering the carbon number range (through C44) of the sample are needed for establishing the retention times of the individual paraffins and for calibration for quantitative measurements. Hydrocarbons used for standards must be greater than 95 % purity.

7.4 Solvent - A liquid (99 % pure) suitable for preparing a quantitative mixture of hydrocarbons and for dissolving petroleum wax. Cyclohexane has been used successfully. (Warning - Solvents are flammable and harmful if inhaled.)

7.5 Linearity Standard - Prepare a weighed mixture of n-paraffins covering the range between n-C16 to n-C44 and dissolve the mixture in cyclohexane. Use approximately equal amounts of each of the paraffins and a balance capable of determining mass to within 1 % of the mass of each compound added. It is not necessary to include every n-paraffin in this mixture so long as the sample contains n-C16, n-C44, and at least one of every fourth n-paraffin. It will be necessary to prepare the standard sample in cyclohexane, so that the normal paraffins are completely dissolved in the solvent. Solutions of 0.01 mass % n-paraffin have been used successfully. This sample must be capped tightly, to prevent solvent loss which will change the concentration of paraffins in the standard blend.

NOTE 1 - Refer to Practice D4307 for details of how to prepare hydrocarbon mixtures.

7.6 Internal Standard Solution - Prepare a dilute solution of internal standard in cyclohexane in two steps as follows:

7.6.1 Prepare a stock solution containing 0.5 mass % n-C16 in cyclohexane by accurately weighing approximately 0.4 g n-C16 into a 100 mL volumetric flask. Add 100 mL of cyclohexane and reweigh. Record the mass of n-C16 to within 0.001 g and the mass of solution (cyclohexane and n-C16) to within 0.l g.

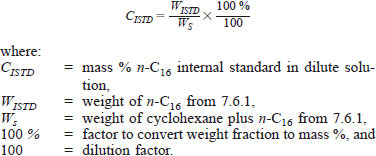

7.6.2 Prepare a dilute solution of n-C16 internal standard by diluting one part of stock solution with 99 parts of cyclohexane. Calculate the concentration of internal standard in the dilute solution using Eq 1.

8. Sampling

8.1 To ensure homogeneity, completely mix the entire wax sample by heating it to 10°C above the temperature at which the wax is completely molten and then mix well by stirring. Using a clean eyedropper, transfer a few drops to the surface of a clean sheet of aluminum foil, allow to solidify and break into pieces. The wax can either be used directly as described in Section 11 or placed in a sealed sample vial until ready for use.

8.1.1 Aluminum foil usually contains a thin film of oil from processing. This oil must be removed by rinsing the foil with solvent such as hexane or mineral spirits, prior to use.