9. Sampling

9.1 MTBE can be sampled either in a floating piston cylinder or into an open container since vapor pressures less than 70 kPa (10 psi) are expected.

9.1.1 Cylinder Sampling - Refer to Practice D3700 for instructions on transferring a representative sample from a source into a floating piston cylinder. Add inert gas to the ballast side of the piston to achieve a pressure of 310 kPa (45 psi) above the vapor pressure of the sample.

9.1.2 Open Container Sampling - Refer to Practice D4057 for instructions on manual sampling from bulk storage into open containers. Stopper container immediately after drawing sample.

9.2 Preserve the sample by cooling to approximately 4 °C and by maintaining that temperature until immediately prior to analysis.

9.3 Transfer an aliquot of the cooled sample into a precooled septum vial, then seal appropriately. Obtain the test specimen for analysis directly from the sealed septum vial, for either manual or automatic syringe injection.

10. Preparation of Apparatus

10.1 Install and condition column in accordance with manufacturer's or supplier's instructions. After conditioning, attach column outlet to flame ionization detector inlet and check for leaks throughout the system. When leaks are found, tighten or replace fittings before proceeding.

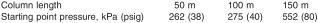

10.2 Adjust the carrier gas flow rate so that an average linear velocity at the starting temperature of the run is between 21 and 24 cm/s, as determined in Eq 1. Flow rate adjustment is made by raising or lowering the carrier gas pressure (head pressure) to the injector. The following starting point pressures can be useful to adjust the carrier gas flow:

10.2.1 Average Linear Gas Velocity:

uave = L/tm

where:

L = the length of the column in cm, and

tm = the retention time in seconds of methane.

10.3 Adjust the operating conditions of the gas chromatograph to conform to the list in Table 1. Turn on the detector, ignite the flame, and allow the system to equilibrate.

10.4 When the method is first set up, ensure that the FID is not saturated. Plot the peak area versus MTBE concentration for prepared standards in the concentration range of interest. If the plot is not linear, increase the split ratio, or use a less sensitive detector range, or both.

11. Column Evaluation and Optimization

11.1 In order to establish that the column/temperature program will perform the required separation, the resolution between cis-2-pentene and tert-butanol and between trans-2-pentene and tert-butanol must be determined. The retention of tert-butanol relative to cis- and trans-2-pentene is very temperature dependent. The order of elution of cis-2-pentene and tert-butanol reverses at subambient temperature. A column which does not resolve these components after adjusting operating conditions is unsuitable.

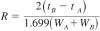

11.2 Analyze a standard mixture that contains approximately 1 % each of tert-butanol, cis-2-pentene, and trans-2-pentene in MTBE by the procedure in Section 13. Calculate resolution (R) between tert-butanol and cis-2-pentene and between trans-2-pentene and tert-butanol using Eq 2. Both resolutions must be at least 1.3.

where:

R = resolution,

tA = retention time Component A,

tB = retention time Component B,

WA = peak width at half height of Component A, and

WB = peak width at half height of Component B and tB > tA

12. Calibration and Standardization

12.1 Component peaks from a sample analysis are identified by matching their retention time with the retention time of reference compounds analyzed under identical conditions. Typical retention times of most common contaminants in MTBE products are listed in Table 2. Analyze mixtures containing these compounds to verify their retention times. Mixtures used for determining retention times can be blended from pure compounds or purchased. Retention times of other suspected contaminants can be established by analyzing mixtures containing these materials under identical conditions. A typical chromatogram ofa MTBE product sample, analyzed on the 150 meter column, is shown in Fig. 1. The peaks are indexed to Table 2.

12.2 Typical mass relative response factors are found in Table 2. These response factors must be verified by analyzing a prepared standard with concentrations similar to those encountered in a MTBE product sample and comparing the measured results with the prepared composition. If the measured composition does not agree with the prepared composition, the response factors should be experimentally determined according to Practice D4626 by measuring the response factors of certified blends that have been purchased or blends prepared according to Practice D4307.