ASTM D5291 Standard Test Methods for Instrumental Determination of Carbon, Hydrogen, and Nitrogen in Petroleum Products and Lubricants

9. Procedure

9.1 Test Method A:

9.1.1 Accurately to within +/-1 mg weigh out about 50 to 200 mg of homogenous test specimen taken according to Practices D4057 or D4177, in a capsule. Crimp the capsule with a forceps.

9.1.1.1 Weigh the solid samples in tin capsules.

9.1.1.2 Weigh the liquid samples in copper capsules and saturate with an absorbent (magnesium oxide) within the copper capsules. Seal the copper capsules with tin plugs. These precautions will induce a slower combustion to prevent any back flashes with the light samples, or incomplete sample combustion.

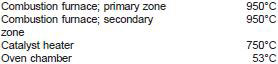

9.1.2 The following typical settings may be used.

9.1.2.1 Temperatures:

9.1.2.2 Oxygen and helium carrier gas pressures should be 40 psi each.

9.1.2.3 Typical settings for gas flows are:

Helium - 400 cm3/min (normal flow)

70 cm3/min (conservation flow)

Oxygen - 7 dm3/min

Air - 6 dm3/min

9.1.3 To start the sequence of analysis, run two to four blank capsules, followed by five calibration standards. The results must agree within +/-10 % for blanks, and +/-1 % of the theoretical value for calibration standards.

9.1.4 Hold all the results in the instrument memory, and recall the best values for the calibration. Enter these results and the known calibrant concentrations into the microprocessor to generate a one point calibration curve.

9.1.5 Analyze the calibration standard again to check the new curve. The results should differ by less than 1 %, or repeat the calibration.

9.1.6 Combust the encapsulated sample in a manner similar to the calibrant. Depending on the sample matrices, set varying oxygen flow rates and combustion times to overcome incomplete combustion.

9.2 Test Method B:

9.2.1 Accurately to within +/-0.02 mg weigh out 2 to 4 mg of a homogeneous test specimen taken according to Practices D4057 or D4177, into the vial. Pinch the center of the vial with a forceps and fold it in half. Flatten the vial with the tweezers, and fold the vial in thirds.

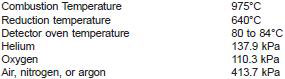

9.2.2 The following typical settings may be used.

9.2.3 Run two to four blanks through the system. Run a conditioning sample followed by another blank. Repeat this sequence.

9.2.4 Run a calibration standard and obtain a response factor, (K), that is calculated as: detector counts for standard/mass of nitrogen, carbon, or hydrogen in the standard.

9.2.5 If the response factors obtained are within manufacturer's specifications, run the samples.

9.3 Test Method C:

9.3.1 Accurately to within +/-0.02 mg weigh out about 5 mg of homogeneous test specimen taken according to Practices D4057 or D4177, in a tin capsule. Crimp the capsule closed with a forceps.

9.3.2 For liquid samples, add about 30 mg of Chromosorb to the tin capsule after weighing the sample.

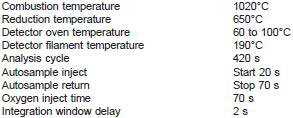

9.3.3 The following typical settings may be used.

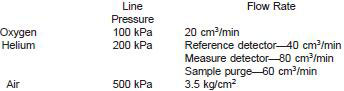

9.3.4 Typical settings for gas flows are:

9.3.5 To start the sequence of analysis, run one unweighed sample to determine retention times, followed by one to two blank capsules, two to three calibration samples for a response factor calculation or three to six calibration samples for a linear regression calculation, then unknown samples.

9.3.6 Randomly insert standards during the analysis of samples to check and update the calibration. The placement and frequency of standards is dependent on sample type and change in analytical conditions, however, a good rule of thumb is one standard for every ten samples.

10. Calculation

10.1 Calculate the concentrations of carbon, hydrogen, and nitrogen, on the appropriate sample basis, as follows:

where:

A = the percent of the carbon, hydrogen or nitrogen in the sample, mass %,

B = the detector response for carbon, hydrogen or nitrogen in the sample minus response from blank,

C = the detector response for carbon, hydrogen or nitrogen in the standard minus response from blank,

D = the mass of the sample, mg,

E = the mass of the standard, mg, and

F = the percent of the carbon, hydrogen or nitrogen in the standard, mass %.

10.2 The calculation can be automatically provided by the instrumental system used for these test methods.