ASTM D5186 Standard Test Method for Determination of the Aromatic Content and Polynuclear Aromatic Content of Diesel Fuels and Aviation Turbine Fuels By Supercritical Fluid Chromatography

8. Preparation of Apparatus

8.1 Install the SFC instrumentation in accordance with the manufacturer's instructions. System operating conditions will depend upon the column used and optimization of performance. Conditions listed in Table 1 have been used successfully. If the performance characteristics in terms of retention and resolution, specified in 8.2, are not achieved, modify the temperature, pressure, or mobile phase flow rate to achieve compliance. A column of low activity may be reactivated by solvent rinsing using established liquid chromatography activation techniques.

NOTE 1 - This temperature can be increased (up to 40°C) if the resolution between the monoaromatics and polynuclear aromatics is not satisfactory. Lower temperatures are suggested to improve resolution between nonaromatics and monoaromatics.

8.2 System Performance:

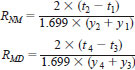

8.2.1 Resolution - Analyze the performance mixture prepared in 7.6. The resolution between the nonaromatics and monoaromatics (RNM) must be at least four and resolution between the monoaromatics and polynuclear aromatics (RMD) must be at least two when calculated in accordance with the following equations:

where:

t1 = time for the n-C 16 peak apex, s,

t2 = time for the toluene peak apex, s,

t3 = time for the tetralin peak apex, s,

t4 = time for the naphthalene peak apex, s,

y1 = peak width at half height of n-C16 peak, s,

y2 = peak width at half height of toluene, s,

y3 = peak width at half height of tetralin, s, and

y4 = peak width at half height of naphthalene, s.

8.2.2 Retention Time Reproducibility - Repeated injections of the performance mixture must show a retention time repeatability (maximum difference between duplicate runs) of not more than 0.5 % for n-C16 and toluene peaks.

8.2.3 Detector Accuracy Test - This test method assumes that the FID response approximates the theoretical unit carbon response. To verify this assumption, analyze the performance mixture and calculate the response factors, relative to hexadecane (RRFi), for each of the components in the performance mix, using the following equations:

where:

Ai = Component i in performance mix, area %,

Mi = Component i in performance mix, known mass %,

RFi = response factor of Component i,

RFC16 = response factor of hexadecane in performance mix, and

RRFi = relative response factor of Component i.

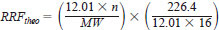

These values can then be compared to the theoretical response factor for each component in the performance mix as calculated by the following equation:

where:

12.01 = atomic mass of carbon,

n = number of carbon atoms in component molecule,

MW = molecular mass of component,

226.4 = molecular mass of hexadecane, and

16 = number of carbon atoms in hexadecane molecule.

The measured RRF for each component in the test mixture must be within ±10 % of the theoretical value as calculated with Eq 5 or summarized in Table 2. If this is not attained, it will be necessary to vary the injection volume, restrictor position, or detector gas flows, or combination thereof, until agreement is attained.

8.2.4 Detector Linearity Check:

8.2.4.1 The following procedure has been found to be useful for verifying detector linearity. It is recommended that the range of aromatics covers at least the samples to be analyzed. However, the size of the hexadecane (n-C16) diluent peak tends to exceed the linear range of the FID. Should this occur, the detector accuracy test (see 8.2.3) provides one indication of linear performance.

8.2.4.2 Select a motor diesel or aviation turbine fuel that has an aromatics content equal to or greater than the maximum concentration to be analyzed. Accurately prepare two weighed blends of this fuel in n-C16. The mass dilutions should nominally contain fuel and n-C16 in proportions of 1:1 and 1:3.

8.2.4.3 Analyze the fuel and two blends by the procedure in Section 9. Determine the measured mass % aromatics present in the neat fuel and each blend as described in Section 10.

8.2.4.4 Calculate the expected concentration of aromatics in the two blends using the following equation:

where:

A = aromatics in the original fuel, mass %,

B = expected aromatics in the diluted fuel, mass %,

C = mass of hexadecane in the dilution, and

D = mass of original diesel fuel in the dilution.

8.2.4.5 Compare the measured results obtained for mass % aromatics in the two dilutions with their corresponding expected aromatics results. These values should agree to within the repeatability limits stated in 13.1.1. If agreement is not obtained, it may be necessary to adjust restrictor position or FID gas flows, clean the FID, or decrease the injection volume.