ASTM D5185 Standard Test Method for Determination of Additive Elements, Wear Metals, and Contaminants in Used Lubricating Oils and Determination of Selected Elements in Base Oils by Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES)

16. Report

16.1 Report mg/kg to three significant figures for calcium, magnesium, zinc, barium, phosphorus, and sulfur. Report mg/kg to two significant figures for aluminum, boron, chromium, copper, iron, lead, manganese, molybdenum, nickel, potassium, sodium, silicon, silver, tin, titanium and vanadium.

17. Precision and Bias

17.1 Precision - The precision of this test method was determined by statistical analysis of interlaboratory results. In this study, dilution solvents were limited to xylene or kerosine. Some laboratories chose to use Babington-type nebulizers, peristaltic pumps, and background correction. Fourteen laboratories analyzed twelve specimens in duplicate. The samples were: one gas turbine used oil, four gasoline engine used oils, two truck diesel engine used oils, two marine engine used oils, SRM 1085 diluted in SRM 1083 (base oil) to contain approximately 40 mg/kg of eleven different metals (this oil also contained 8 mass % of an ethylene-propylene copolymer viscosity index improver), SRM 1085 diluted in SRM 1083 to contain approximately 40 mg/kg of twelve different metals, SRM 1085 diluted in SRM 1083 to contain approximately 2 mg/kg of 12 different metals.

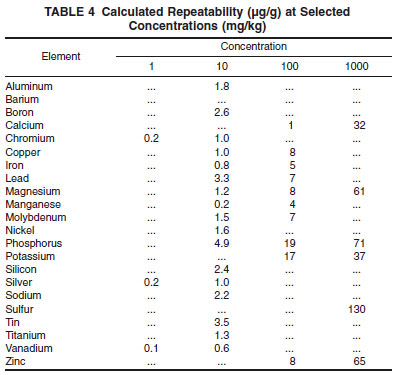

17.1.1 Repeatability - The difference between two test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values in Table 2 and Table 4 only in one case in twenty.

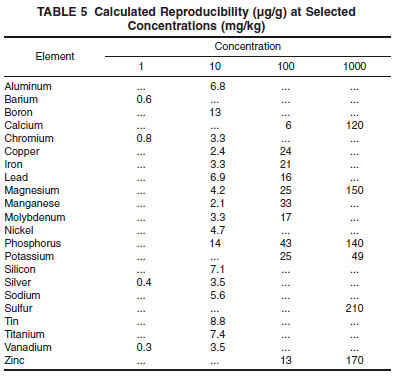

17.1.2 Reproducibility - The difference between two single and independent results, obtained by different operators working in different laboratories on identical test materials, would in the long run, in the normal and correct operation of the test method, exceed the values in Table 3 and Table 5 only in one case in twenty.

17.1.3 Parametric representations of precision, calculated separately for the set of three base oil dilutions of NIST SRM 1085, are essentially the same, within experimental error, as the precision listed in Table 2 and Table 3.

17.2 Bias - Bias was evaluated by analyzing quantitative dilutions of SRM 1085, that contains oil-soluble metals rather than insoluble particulates. The means of the reported values for Al, Cr, Cu, Fe, Pb, Mg, Mo, Ni, Si, Ag, Sn, and Ti do not differ from the corresponding expected values by more than the repeatability of the method, when no significant interferences from other elements exist (see 6.1).

18. Keywords

18.1 additive-elements; aluminum; barium; boron; calcium; chromium; copper; emission-spectrometry; ICP; inductively coupled plasma atomic emission spectrometry; iron; lead; lubricating oils; magnesium; manganese; molybdenum; nickel; phosphorous, potassium; silicon; silver; sodium; sulfur; tin; titanium; vanadium; wear metals; zinc