ASTM D5134 Standard Test Method for Detailed Analysis of Petroleum Naphthas through n-Nonane by Capillary Gas Chromatography

12. Procedure for Gas Chromatographic Analysis of Sample

12.1 Set the instrument operating variables to within the limits specified in Table 2. If necessary, change split ratio, sample size, or injection port temperature, or combination thereof, to ensure splitter linearity as determined in Section 11.

12.2 Verify that the isothermal retention time of toluene (at 35°C) is 29.6 more or less 0.2 min as discussed in 9.4.

12.3 Set the recorder or integration device, or both, for accurate presentation of the data. Set up instrument sensitivity such that any component of at least 0.05 % mass will be detected, integrated, and reported.

12.4 Inject 0.2 to 1.0 µL of sample into the injection port and start the analysis. Sample size must be consistent with the splitter linearity range as determined in Section 11. Obtain a chromatogram and peak integration report.

NOTE 3 - Petroleum naphtha samples may contain appreciable quantities of highly volatile components. Samples should be chilled in their original container to 4°C (39°F) before opening for subsampling or transfer (see Section 8).

13. Calculation

13.1 Identify each peak by visually matching it with its counterpart in the appropriate standard chromatogram, Fig. 1, Fig. 2, or Fig. 3. Make allowances for differences in relative peak sizes with different samples. Peaks eluting after n-nonane are not identified individually.

NOTE 4 - To aid the analyst in setting up this test method and identifying peaks in the chromatograms, qualitative reference samples of the alkylate, naphtha, and reformate actually used to generate Fig. 1, Fig. 2, and Fig. 3 are available. Each can be analyzed and its chromatogram compared directly with the corresponding figure to assist in peak assignments.

13.2 Each peak can also be identified by matching its retention index with that of the compounds listed in Table 1. Equations for calculating retention indices are given in Annex A1. Retention indices of compounds eluted during the initial isothermal portion of the analysis must be calculated using the Kovats equation. Retention indices of all other components must be calculated using the equation for linear indices. Differences from the values in the table must be allowed for due to slight differences in columns, temperature, and flow. As noted in 11.1, retention times and therefore retention indices also vary as a result of column overload.

13.3 If a computing integrator is used for automatic identification, examine the report to ensure peaks are properly identified.

NOTE 5 - Caution: Careful review of peak identifications is extremely important. Failure to do so may result in serious errors.

13.4 Sum the areas of all peaks eluting after n-nonane. This group will be treated as a single component, C10+.

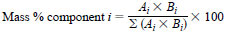

13.5 Calculate the mass percent of each component (including C10+) according to the following equation:

where:

Ai = area of peak representing component i, and

Bi = relative mass response factor for component i. Use a response factor of 1.00 for all components except benzene (0.90) and toluene (0.95).

NOTE 6 - Relative mass response factors determined using quantitative calibration standards may be substituted for the assigned factors in 13.5. However, the reproducibility of the test method (Table 3) is based on data calculated using the assigned factors. Differences in inter-laboratory results on the same sample may exceed the published reproducibility values as a result of using empirically determined response factors.