TEST METHOD B (SCATTERED TUNGSTEN RADIATION)

11. Apparatus

11.1 X-ray Spectrometer, capable of measuring radiations mentioned in 3.1.2 and of being operated under the following instrumental conditions or others giving equivalent results:

Tube Voltage: 50 kV

Tube Current: 20 to 45 mA

Tube Target: Tungsten

Analyzing Crystal: Lithium Fluoride (LiF)

Optical Path: Air, Helium (Warning - Compressed gas under pressure)

Collimation: Fine

Pulse Height Analyzer: Threshold discrimination set as low as possible consistent with the removal of noise with respect to the detector employed.

Detector: Proportional or Scintillation

Counting Technique: Fixed Time

11.1.1 Two restrictions are imposed upon the period of the fixed time: namely, that it is 30 s or greater, and that it is such that the count on the position of minimum intensity (background at A = 1.211 Å) should exceed 200 000.

NOTE 9 - The X-ray spectrometer and manner of use should comply with the regulations governing the use of ionizing radiation or recommendations of the International Commission of Radiological Protection, or both.

12. Reagents and Materials

12.1 Iso-octane. (Warning - Extremely flammable.)

12.2 Lead (Pb) Standard Solution - Dissolve tetraethyllead (TEL) (Warning - TEL is toxic by ingestion), lead naphthenate (see Note 4), or other suitable lead containing compound in iso-octane (Warning - Extremely flammable), toluene, or a mixture of these two solvents. When TEL is used, refer to Note 5. This standard solution shall contain an accurately known lead concentration of approximately the following magnitude:

5 g Pb/US gal at 15.5°C (60°F)

6 g Pb/UK gal at 15.5°C (60°F)

1.3 g Pb/L at 15.5°C

12.2.1 Keep the standard solution refrigerated when not in use.

13. Calibration

13.1 Place the standard lead solution in the sample cell using techniques consistent with good operating practice for the spectrometer employed. Insert the cell in the X-ray beam using the instrumental conditions described in Section 10 and allow the spectrometer atmosphere to reach equilibrium (when appropriate). Take one intensity reading at each of the following wavelength settings, then replace the standard solution with a fresh portion and repeat the readings. Repeat this procedure with iso-octane.

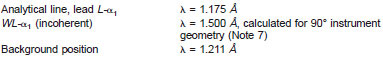

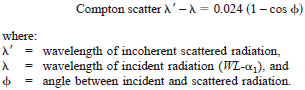

NOTE 10 - Calculated for the case where the angle between the incident radiation and take-off collimator is 90°, using the equation for:

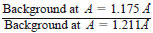

13.2 Determine the corrected background by multiplying the intensity of the background at λ = 1.211 Å by the following ratio obtained on the iso-octane blank:

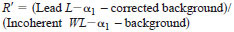

13.3 Take the mean of the two intensity readings at each wavelength setting and calculate the ratio, R', as follows:

13.4 Divide the lead concentration of the standard solution by R' to obtain the calibration factor, F.

14. Quality Control Checks

14.1 Follow the requirements specified in 8.1 for samples analyzed by Test Method B.

15. Procedure

15.1 Obtain sample in accordance with Practice D4057.

15.2 Remove the standard lead solution and the gasoline samples from the refrigerator and bring them to room temperature.

15.3 Establish the calibration factor, F, as described in 13.4. This must be done each day the method is in use.

15.4 Determine the ratio, R', for the samples as shown in 13.1, 13.2, and 13.3 and obtain the lead content of the samples by multiplying R' by the calibration factor, F.

16. Report

16.1 Report the lead content obtained as g Pb/UK gal at 15.5°C (60°F), g Pb/US gal at 15.5°C (60°F) to the nearest 0.01 g or g Pb/L at 15.5°C to the nearest 0.003 g, as appropriate (see Note 4).