11. Procedure

11.1 Introduce about 0.7 mL of crude oil into the clean, dry, sample tube of the instrument using a suitable syringe. Leave the syringe in place and plug the exit port.

11.2 Turn on the illumination light and examine the sample tube carefully. Make sure that there is no obvious presence of bubbles trapped in the U-tube, and that it is filled completely. The sample must appear to be homogeneous. Turn the illumination light off immediately after inspection of the sample tube, since the heat generated affects the measurement temperature.

11.3 Allow the sample to equilibrate to the test temperature before proceeding to evaluate the test sample for the presence of unseen air or gas bubbles.

11.4 For dark crude oil samples the observation of air or gas bubbles in the sample tube is very difficult. The presence of bubbles can often be detected, however, by observing the fluctuations of the digital display of the T-value or density value. Air or gas bubbles cause large random variations in the third and fourth significant figures for density reading and fifth and sixth significant figures for T readings. When bubbles are absent and the sample is at equilibrium with the test temperature, the displayed values are stable, do not drift, and show only small variations of the order of more or less 1 to 2 units in the last significant figure. If stable values are not observed after a few minutes, then repeat the injection of a new sample into the tube.

NOTE 4 - When viscous liquids are being measured, a stable reading can be achieved even when air or gas bubbles are present. Careful injection of fresh sample will often eliminate bubbles. Since bubbles contribute to lower density readings, an observed increase in the density of the liquid after injection of fresh sample tends to suggest that bubbles were previously present.

11.5 After the instrument displays a steady reading to four significant figures for density and five for T-values, indicating that temperature equilibrium has been reached, record the density or T-value.

11.6 Flush and dry the sample tube as described in 10.2.1 and check the calibration as described in 10.3.1 prior to introducing another sample.

12. Calculation

12.1 Calculating Density Analyzers - The recorded value is the final result, expressed either as density in g/mL, kg/m3 or as relative density. Note that kg/m3 = 1000 x g/mL.

12.2 Noncalculating Density Analyzers - Using the observed T-value for the sample and the T-value for water and appropriate instrument constants determined in 10.4.3, calculate the density or relative density using Eq 6 and Eq 7. Carry out all calculations to six significant figures and round the final results to four. Note that kg/m3 = 1000 x g/mL.

for density:

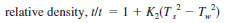

for relative density:

where:

Tw = observed period of oscillation for cell containing water,

Ts = observed period of oscillation for cell containing sample,

dw = density of water at test temperature,

K1 = instrument constant for density,

K2 = instrument constant for relative density, and

t = temperature of test, °C.

12.3 If it is necessary to convert a result obtained using the density analyzer to a density or relative density at another temperature, Guide D1250 can be used only if the table values have not been corrected for the glass expansion factor.