9. Preparation of Apparatus

9.1 Set up the density analyzer and constant temperature bath following the manufacturer's instructions. Adjust the bath or internal temperature control so that the desired test temperature is established and maintained in the sample compartment of the analyzer. Calibrate the instrument at the same temperature at which the density of the sample is to be measured.

10. Calibration of Apparatus

10.1 Calibrate the instrument when first setting up and whenever the test temperature is changed. Thereafter, conduct calibration checks at least weekly during routine operation or more frequently as may be dictated by the nature of the crude oils being measured (see 10.3).

10.2 Initial calibration, or calibration after a change in test temperature, necessitates calculation of the values of the Constants A and B from the periods of oscillation, (T), observed when the sample cell contains certified reference liquids such as air and double-distilled boiled water. Other calibrating materials such as n-nonane, n-tridecane, cyclohexane, and n-hexadecane (for high temperature applications) can also be used as appropriate.

10.2.1 While monitoring the oscillator period, T, flush the sample tube with petroleum naphtha, followed with an acetone flush and dry with dry air. Continue drying until the display exhibits a steady reading. In cases where saline components can be deposited in the cell, flush with distilled water followed by acetone and dry air. Contaminated or humid air can affect the calibration. When these conditions exist in the laboratory, pass the air used for calibration through a suitable purification and drying train. In addition, the inlet and outlet ports for the U-tube must be plugged during measurement of the calibration air to prevent ingress of moist air.

10.2.2 Allow the dry air in the U-tube to come to thermal equilibrium with the test temperature and record the T-value for air.

10.2.3 Introduce about 0.7 mL of freshly boiled and cooled double-distilled water into the sample tube from the bottom opening using a suitable syringe. The water must be free of even the smallest air or gas bubbles. The sample tube shall be completely full. Allow the water to reach thermal equilibrium at the test temperature and record the T-value for water and the test temperature.

10.2.4 Alternatively introduce one of the hydrocarbon calibration standards and measure the T-value as in 10.2.3.

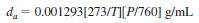

10.2.5 Calculate the density of air at the temperature of test using the following equation:

where:

T = temperature, K, and

P = barometric pressure, torr.

10.2.6 Determine the density of water at the temperature of test by reference to Table 1.

10.2.7 Alternatively record the density at the test temperature for the hydrocarbon calibrant used in 10.2.4 as obtained from an appropriate reference source or from direct determination (see 7.6).

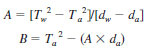

10.2.8 Using the observed T-values and the reference values for water and air, calculate the values of the Constants A and B using the following equations:

where:

Tw = observed period of oscillation for cell containing water,

Ta = observed period of oscillation for cell containing air,

dw = density of water at test temperature, and

da = density of air at test temperature.

Alternatively, use the T and d values for the other reference liquid if one is used.

10.2.9 If the instrument is equipped to calculate density from the Constants A and B and the observed T-value from the sample, then enter the constants in the instrument memory in accordance with the manufacturer's instructions.

10.2.10 Check the calibration and adjust if needed by performing the routine calibration check described in 10.3.

10.2.11 To calibrate the instrument to determine relative density, that is, the density of the sample at a given temperature referred to the density of water at the same temperature, follow 10.2.1-10.2.9, but substitute 1.000 for dw in performing the calculations described in 10.2.8.

10.3 Since some crude oils can be difficult to remove from the sample tube, frequent calibration checks are recommended. These checks and any subsequent adjustments to Constants A and B can be made if required, without repeating the calculation procedure.

NOTE 2 - The need for a change in calibration is generally attributable to deposits in the sample tube that are not removed by the routine flushing procedure. Although this condition can be compensated for by adjusting A and B, as described below, it is good practice to clean the tube with warm chromic acid solution (Warning - Causes severe burns. A recognized carcinogen.) whenever a major adjustment is required. Chromic acid solution is the most effective cleaning agent; however, surfactant-type cleaning fluids have also been used successfully.

10.3.1 Flush and dry the sample tube as described in 10.2.1 and allow the display to reach a steady reading. If the display does not exhibit the correct T-value or density for air at the temperature of test, repeat the cleaning procedure or adjust the value of Constant B commencing with the last decimal place until the correct density is displayed.

10.3.2 If adjustment to Constant B was necessary in 10.3.1 then continue the recalibration by introducing freshly boiled and cooled double-distilled water into the sample tube as described in 10.2.3 and allowing the display to reach a steady reading. If the instrument has been calibrated to display the density, adjust the reading to the correct value for water at the test temperature (see Table 1) by changing the value of Constant A, commencing with the last decimal place. If the instrument has been calibrated to display the relative density, adjust the reading to the value 1.0000.

NOTE 3 - In applying this periodic calibration procedure, it has been found that more than one value each for A and B, differing in the fourth decimal place, will yield the correct reading for the density of air and water. The setting chosen would then be dependent upon whether it was approached from a higher or lower value. The setting selected by this method could have the effect of altering the fourth place of the reading obtained for a sample.

10.4 Some analyzer models are designed to display the measured period of oscillation only (T-values) and their calibration requires the determination of an instrument constant K, that must be used to calculate the density or relative density from the observed data. Use the procedure in 10.4.1, 10.4.2, and 10.4.3 in this case.

10.4.1 Flush and dry the sample tube as described in 10.2.1 and allow the air to reach equilibrium at the test temperature and the readout to display a steady value. Record the T-value for air.

10.4.2 Introduce freshly boiled and cooled double-distilled water into the sample tube as described in 10.2.3, allow the display to reach a steady reading and record the T-value for water.

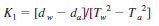

10.4.3 Using the observed T-values and the reference values for water and air (10.2.5 and 10.2.6), calculate the instrument constant, K, using the following equations:

for density:

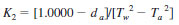

for relative density:

where:

Tw = observed period of oscillation for cell containing water,

Ta = observed period of oscillation for cell containing air,

dw = density of water at test temperature, and

da = density of air at test temperature.