13. Report

13.1 Report the following information:

13.1.1 Wear scar diameter to the nearest 0.01 mm (from 12.2),

13.1.2 Description of the wear scar area, and

13.1.3 Deviations from the standard conditions of the test load, relative humidity, and fuel temperature, etc. (Fig. 3).

14. Precision and Bias

14.1 Precision - The precision of this test method as obtained by statistical analysis of interlaboratory test results should be used for judging the acceptability of results (95 % of confidence). The interlaboratory study was carried out on both the semi-automatic and fully automatic instruments, using 10 fuel samples and 8 participating laboratories.

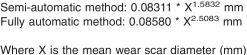

14.2 Repeatability - The difference between successive test results, obtained by the same operator with the same apparatus under constant operating conditions on identical test material would, in the long run, and in the normal and correct operation of the test method exceed the following values in only one case in twenty:

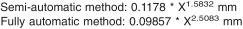

14.3 Reproducibility - The difference between two single and independent results, obtained by different operators working in different laboratories on identical test material would, in the long run, and in the normal and correct operation of the test method exceed the following values in only one case in twenty:

14.4 Relative Bias Between the Semi-Automatic and Fully Automatic Test Methods - There is no statistically significant relative bias between the two methods according to Practice D6708.

14.5 Bias - The procedure in this test method has no bias because lubricity is not a fundamental and measurable fluid property.

15. Keywords

15.1 aviation turbine fuel; BOCLE; boundary lubrication; jet fuel; lubricity; wear; wear scar