7. Preparation of Test Specimen

7.1 If the sample is not sufficiently fluid as received, heat the sample with care, stirring when possible to prevent local overheating, until it has become sufficiently fluid to pour. In no case should the temperature be raised to more than 60°C above the expected softening point for tar pitch in accordance with Test Method D36, or to more than 90°C above it for petroleum asphalt (bitumen). Heat samples for the minimum time necessary to ensure that they are sufficiently fluid. Stir to ensure that the sample is homogeneous. Avoid incorporating bubbles into the sample.

7.2 Pour the sample into the sample container to a depth such that, when cooled to the temperature of test, the depth of the sample is at least 120% of the depth to which the needle is expected to penetrate. Pour separate portions for each variation in test conditions. If the sample container is less than 65 mm in diameter and the expected penetration is greater than 200, pour three separate portions for each variation in test conditions.

NOTE 4 - If sufficient material is available it is recommended to fill the sample container to near the brim.

7.3 Allow to cool in air at a temperature between 15 and 30°C for 45 min to 1.5 hr for the small (33 x 16 mm or less) containter, 1 to 1.5 h for the medium (55 x 35 mm) container and 1.5 to 2 h for larger containers. Then place the samples together with the transfer dish, if used, in the water bath maintained at the prescribed temperature of test. Allow the small (33 x 16 mm or less ) container to remain for 45 min to 1.5 hr, the medium (55 x 35 mm) container to remain for 1 to 1.5 h and the larger containers to remain for 1.5 to 2 h.

NOTE 5 - If conditions warrant, it is appropriate to loosely cover each container as a protection against dust. A convenient way of doing this is by covering with a lipped beaker.

8. Test Conditions

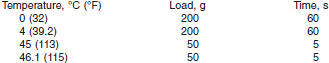

8.1 Where the conditions of test are not specifically mentioned, the temperature, load, and time are understood to be 25°C (77°F), 100 g, and 5 s, respectively. Other conditions may be used for special testing, such as the following:

In such cases the specific conditions of test shall be reported.