6. Apparatus

6.1 Penetration Apparatus - Any apparatus that permits the needle holder (spindle) to move vertically without measurable friction and is capable of indicating the depth of penetration to the nearest 0.1 mm, will be acceptable. The weight of the spindle shall be 47.5 ± 0.05 g. The total weight of the needle and spindle assembly shall be 50.0 ± 0.05 g. Weights of 50 ± 0.05 g and 100 ± 0.05 g shall also be provided for total loads of 100 g and 200 g, as required for some conditions of the test. The surface on which the sample container rests shall be flat and the axis of the plunger shall be at approximately 90° to this surface. The apparatus shall have a leveling indicator. The spindle shall be easily detached for checking its weight.

6.1.1 The leveling indicator shall be verified at least annually with a hand-held level.

6.2 Penetration Needle:

6.2.1 The needle (see Fig. 1) shall be made from fully hardened and tempered stainless steel, Grade 440-C or equal, HRC 54 to 60. The standard needle shall be approximately 50 mm (2 in.) in length, the long needle approximately 60 mm (2.4 in.). The diameter of all needles shall be 1.00 to 1.02 mm (0.0394 to 0.0402 in.). It shall be symmetrically tapered at one end by grinding to a cone having an angle between 8.7 and 9.7° over the entire cone length. The cone should be coaxial with the straight body of the needle. The total axial variation of the intersection between the conical and straight surfaces shall not be in excess of 0.2 mm (0.008 in.). The truncated tip of the cone shall be within the diameter limits of 0.14 and 0.16 mm (0.0055 and 0.0063 in.) and square to the needle axis within 2°. The entire edge of the truncated surface at the tip shall be sharp and free of burrs. When the surface texture is measured in accordance with American National Standard B 46.1 or ISO 468 the surface roughness height, Ra, of the tapered cone shall be 0.2 to 0.3 µm (8 to 12 µin.) arithmetic average. The surface roughness height, Ra, of the needle shank shall be 0.025 to 0.125 µm (1 to 5 µin.). The needle shall be mounted in a non-corroding metal ferrule. The ferrule shall be 3.2 ± 0.05 mm (0.126 ± 0.002 in.) in diameter and 38 ± 1 mm (1.50 ± 0.04 in.) in length. The exposed length of the standard needle shall be within the limits of 40 to 45 mm (1.57 to 1.77 in.), and the exposed length of the long needle shall be 50 to 55 mm (1.97 to 2.17 in.). The needle shall be rigidly mounted in the ferrule. The run-out (total-indicator reading) of the needle tip and any portion of the needle relative to the ferrule axis shall not exceed 1 mm (0.04 in.). The weight of the ferrule needle assembly shall be 2.50 ± 0.05 g. (A drill hole at the end of the ferrule or a flat on the side is permissible to control the weight.) Individual identification markings shall be placed on the ferrule of each needle; the same markings shall not be repeated by a manufacturer within a 3-year period.

6.2.2 Needles used in testing materials for conformance to specifications shall be shown to have met the requirements of 6.2.1 when tested by a qualified agency.

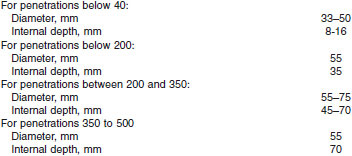

6.3 Sample Container - A metal or glass cylindrical, flat-bottom container of essentially the following dimensions shall be used:

NOTE 2 - For referee testing, the container for testing materials with penetrations below 40 shall be 55 x 35 mm.

6.4 Water Bath - A bath capable of maintaining a temperature of 25 ± 0.1°C (77 ± 0.2°F) or any other temperature of test within 0.1°C. The bath shall have a perforated shelf supported in a position not less than 50 mm from the bottom and not less than 100 mm below the liquid level in the bath. If penetration tests are to be made in the bath itself, an additional shelf strong enough to support the penetrometer shall be provided. Brine may be used in the bath for determinations at low temperatures.

NOTE 3 - The use of distilled water is recommended for the bath. Take care to avoid contamination of the bath water by surface active agents, release agents, or other chemicals; as their presence may affect the penetration values obtained.

6.5 Transfer Dish - When used, the transfer dish shall have a capacity of at least 350 mL and of sufficient depth of water to cover the large sample container. It shall be provided with some means for obtaining a firm bearing and preventing rocking of the container. A three-legged stand with three-point contact for the sample container is a convenient way of ensuring this.

6.6 Timing Device - For hand-operated-penetrometers any convenient timing device such as an electric timer, a stop watch, or other spring activated device may be used provided it is graduated in 0.1 s or less and is accurate to within ±0.1 s for a 60-s interval. An audible seconds counter adjusted to provide 1 beat each 0.5 s may also be used. The time for a 11-count interval must be 5 ± 0.1 s. Any automatic timing device attached to a penetrometer must be accurately calibrated to provide the desired test interval within ±0.1 s.

6.7 Thermometers - Calibrated liquid-in-glass thermometers of suitable range with subdivisions and maximum scale error of 0.1°C (0.2°F) or any other thermometric device of equal accuracy, precision and sensitivity shall be used. Thermometers shall conform to the requirements of Specification E 1 or Specification E 2251. Other thermometric devices shall conform to the requirements of Specification E 1137.

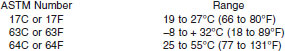

6.7.1 Suitable thermometers commonly used are:

6.7.2 The thermometer used for the water bath shall periodically be calibrated in accordance with Test Method E 77. An alternate thermometric device shall periodically be calibrated in accordance with Specification E 1137.