11. Report

11.1 TMC and Gear Tooth Condition - Report the total mass change of the gears in milligrams, and the numbers of teeth as determined in 9.9. Note the occurrence of any other surface defects (see Appendix X1).

12. Precision and Bias

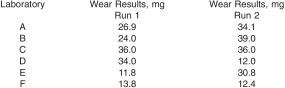

12.1 The precision of this test method was not determined in accordance with currently accepted guidelines (for example, Committee D02's research report RR:D02-1007 "Manual on Determining Precision Data for ASTM Methods on Petroleum Products and Lubricants"). Only one oil was tested in six laboratories. The precision of only the wear portion of the test method was determined by statistical examination of interlaboratory results as follows and is most useful for nominal wear results in the neighborhood of 25 mg:

12.1.1 Intermediate Precision Conditions - Conditions where test results are obtained with the same test method using the same oil, with changing conditions such as operators, measuring equipment, test stands, and time.

NOTE 3 - Intermediate Precision is the appropriate term for this test method, rather than repeatability, which defines more rigorous within-laboratory conditions.

12.1.2 Intermediate Precision Limit (i.p.) - The difference between two test results for wear obtained under intermediate precision conditions that would, in the long run, in the normal and correct conduct of the test method, exceed 27.4 mg in only one case in twenty.

12.1.3 Reproducibility - The difference between two single and independent test results for wear obtained by different operators working in different laboratories on identical test material would, in the long run, in normal and correct operation of the test method, exceed 43.2 mg in only one case in twenty.

12.2 Bias - The procedure in Test Method D4998 has no bias because the value of wear results can be determined only in terms of the test method.

12.3 Results - The test oil used was a heavy-duty transmission oil formulation, SAE 30 viscosity, without added viscosity index improver. All tests were done with 19 L samples of test oil drawn from a single drum and sent to the laboratories. No test gears were distributed. Each laboratory used test gears from its own stock.

13. Keywords

13.1 anti-wear characteristics; fluid; FZG; gear systems; hydraulic fluid; lubricants; petroleum and petroleum products; transmission fluid and gear oil; wear and wear life of lubricants