9. Procedure

9.1 From the dried analysis sample, riffle to obtain a test sample of about 75 g. Weigh the test sample to the nearest 0.01 g and record the mass as Ws.

9.2 Charge an extractor thimble with the test sample, place the thimble in the extractor, and assemble extractor and condenser.

NOTE 3 - Do not use grease on joints. Use TFE-fluorocarbon sleeves to control leaking problems.

9.3 Put two or three clean boiling chips into a clean, dry boiling flask and weigh to the nearest 0.1 mg. Record the mass as W1.

NOTE 4 - Because of the required mass precision, handle the flask with clean tongs or gloves.

9.4 Pour 210 mL of methylene chloride into the boiling flask and assemble it to the extractor.

9.5 Start the cooling water flow to the condenser. Raise the heating mantle to the flask and adjust the power to bring the solvent to a boil. Adjust the heat to control the reflux rate, being careful not to override the capacity of the condenser. About 2 drops/s reflux to the thimble should be satisfactory. An aluminum foil tent around the upper portion of the flask and lower portion of the extractor will help speed up reflux rate.

9.6 After the extractor has gone through four dump cycles, continue heating until the chamber around the sock is two-thirds full. Note the color of the solvent in the thimble region. If it is not clear, continue refluxing through the fifth cycle (dump and fill sock until two-thirds full). Continue in this fashion until the solvent in the thimble region is clear. Several dump cycles can be necessary when excessive fines are present or when the de-dust oil is only mildly soluble (asphalt or "heavy" vacuum reside).

9.7 Bring approximately 200 mL of deionized water to a boil in the 300 mL beaker.

9.8 Remove the flask from the extractor and place it on top of the beaker of boiling water under a fume hood. Start a small flow of air through the bent glass tube, then insert the tube into the neck of the flask being careful not to touch the liquid. Air flow shall be low enough to avoid splattering of the liquid.

9.9 After the methylene chloride has evaporated, dry the outside of the flask, rinse the outside with acetone, then place the flask with its contents in a drying oven (or vacuum oven) at 110 °C +/- 2 °C (and approximately 100 mm Hg), for 15 min.

9.10 Remove the flask from the drying oven and cool to room temperature in a desiccator. Weigh the flask and contents to the nearest 0.1 mg and record the mass as W2.

9.11 Repeat the procedure from 9.1-9.10 with a second test sample.

10. Calculation

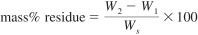

10.1 Calculate the amount of residue as a percent of the original sample mass as follows:

where:

Ws = mass of the test sample, g.

W1 = mass of the boiling flask and chips.

W2 = mass of the boiling flask, chips, and residue.